No serious off-roading enthusiast would ever leave the pavement without a fully functioning winch. The risk of getting stuck in a mud puddle or stranded in a ditch is simply too great, even for experienced drivers. Not to mention recovery winches give Jeepers more freedom and independence. With the help of these durable devices, they can explore rugged trails miles from civilization and pull their Wrangler to safety without any outside help. When shopping for a winch, there are a lot of factors to consider. No one can tell you what winch will work best for you, so the best thing to do is decide what you want to do with a winch and then compare your options.

Contents

- What is a Winch & Types of Winches

- Electric Winch Motors

- How an Electric Winch Works

- What You Need to Operate an Electric Winch

- How Hydraulic Jeep Wrangler Winches Work

- The Pros and Cons of Using Steel Cable

- The Pros and Cons of Synthetic Rope

- What Size Winch Do I Buy for My Jeep?

- Winch Mounting Systems

- Stretching the Cable

- How to Safely Use Your Winch

- How the Winch's Controls Work

- Anchoring a Winch

- How to Use a Winch for Straight Line Recovery

- The Not-So Straight Line Recovery

- Additional Accessories for Your Winch and Recovery

- How to Use Additional Recovery Tools

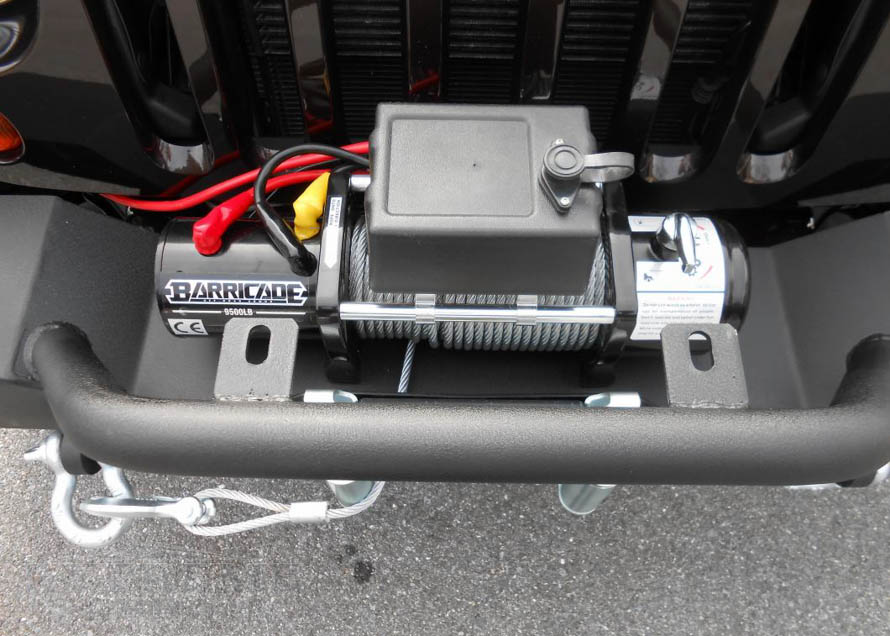

Shop Jeep Wrangler Winches

Having a winch on your Wrangler can save you and others while off-roading. Be sure to select the proper pound rating winch for all of your Jeep's accessories (heavy-duty bumpers, bigger wheels and tires, etc.). Better to be safe than sorry.