How to Install a Teraflex Performance Leveling Kit on your 07-18 Jeep Wrangler JK 4 Door; 2018 Jeep Wrangler JL 4 Door

Installation Time

4 hours

Tools Required

- 10, 14, 15, 16, 17, 18, 19, 21mm sockets and wrenches

- 7/16”, 5/8”, 3/4” sockets and wrenches

- 3/8” &1/2” drive ratchets

- 3”, 6”, & 12” extensions

- Ft-lbs torque wrench

- Breaker bar

- Floor jack

- Jack stands

- Wheel chocks

- Hammer

- Pry bars

- Pliers

- Safety glasses

Shop Parts in this Guide

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize

yourself with the required steps and evaluate if you are experienced and capable

to personally perform these modifications.

Refer to the parts list to ensure that all necessary components and hardware

has been included. If any parts are missing please contact your local retailer for

assistance.

Installation:

1. Remove track bar bolts using a 21mm socket, at both the front and rear axle and remove track bars.

2. Loosen all control arm bolts using a 21mm socket, DO NOT REMOVE ARMS OR BOLTS!

3. Lift the vehicle and support under the frame with jack stands. Make sure that the axle will drop far enough to remove and install the coil

springs.

4. Remove the wheels.

Rear Installation:

5. Support the rear axle with a jack and slightly lift one or two inches so that it is easy to remove the bolts from the shocks. (If you remove the nut from the bolt prior to jacking up on the axle you can put slight pressure on the bolt with your hand while jacking the axle and see where it is easiest to remove the bolts.)

6. Remove the bottom shock bolts using an 18mm socket and wrench.

7. Remove the clips that secure the ABS wiring harness to the upper control arm mount.

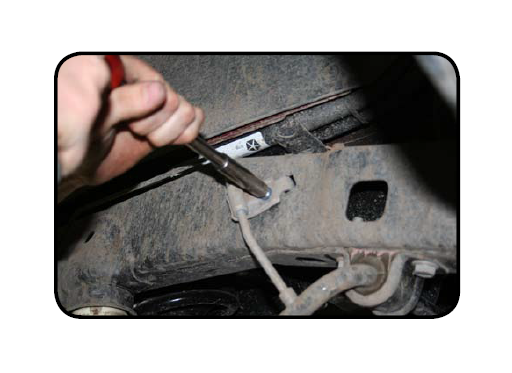

8. Remove the bracket that holds the park brake cables to the body using a 10mm deep well socket.

9. Remove the brake line mount at the frame using a 10mm socket.

10. Carefully lower the rear axle far enough to remove the rear springs. Be careful not to let the coils fall out as you lower the axle. You will want to lower the axle far enough to install the new 1.5” springs in place. While lowering the axle make sure the brake lines, ABS wires and axle vent do not stretch as this could cause damage to these vital parts.

11. Install the new rear springs. Make sure to reuse the factory spring isolator.

12. Jack up the rear axle and replace lower shock bolts. Torque to 56 ft-lbs.

13. Reinstall the brake line mount and torque to 16

ft-lbs.

14. Remove jack from under axle.

15. Rear installation complete.

Front installation:

16. Place jack under the axle and slightly lift the front axle so you can easily remove factory hardware form shocks, sway bar links.

17. Remove the front shocks by using a 18mm wrench and socket at the axle side.

18. Remove sway bar links using 18mm socket and wrench at the axle and 18mm socket and 20mm wrench at the sway bar. Lower the jack enough to remove the springs.

19. Remove front coil springs.

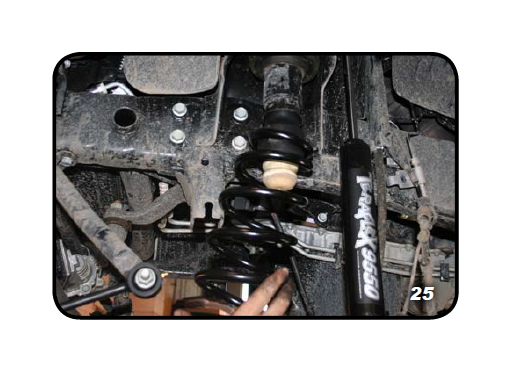

20. Install new 1.5 inch coil springs. Do the drivers side first.

21. Install the new sway bar links on the outside of the sway bar and inside of the axle mount. Torque to 75 ft-lbs.

22. Reinstall the lower shock bolts and torque to 56 ft-lbs.

23. Reinstall wheels, torque lug nuts to 95- 115 ft-lbs, Remove jack stands, lower the vehicle onto its own weight, and torque all the control

arm bolts. Torque the uppers to 75 ft-lbs and the lowers to 125 ft-lbs.

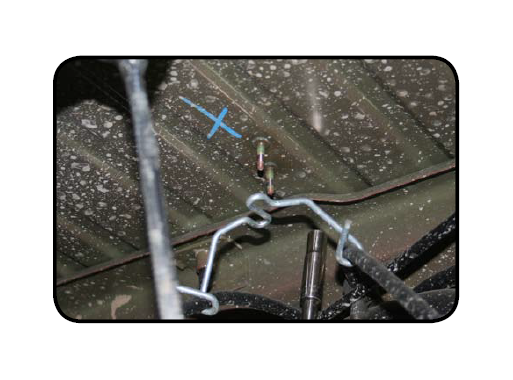

24. Install the rear track bar. To align the rear track bar to the axle have someone push on the body of the jeep until the bolt hole lines up. Torque to 125 ft-lbs.

25. Install the front track bar. To align the front

track bar have someone move the steering

wheel until the bolt hole lines up. Torque to 125

ft-lbs.

26. To straighten the steering wheel, loosen the adjuster sleeve on the drag link by using 15mm sockets. Mark the position by making a line across the sleeve and the threads this line will indicate the original position. Looking from the drivers side rotate the adjuster sleeve counter clockwise 3/4 of a turn. This should get your steering wheel close to center. Every vehicle is different so test drive yours and determine if yours needs further adjustment. Once steering wheel is straight torque pinch clamp bolts to 45 ft-lbs.

27. Re-torque all fasteners after 300 miles.