How to Install Teraflex BellyUp Skid Plate on your 1987-1995 Wrangler

Shop Parts in this Guide

Think safety first when installing this kit. The installation of this kit will require use of the TeraFlex 231SS or equivalent.

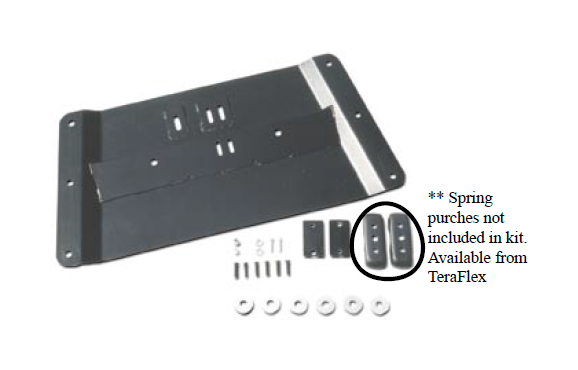

Component list

Please check the components in your kit prior to beginning installation. Each kit should include:

1- Belly Up Skid Plate

2- Engine Mount Nuts

2- 1/2” lock washer

2- Motor Mount Spacers

6- 1/2” x 1/5” Buttonhead bolts

2- 3/8” washer

2- 10mm x 40mm bolt

6- 1/2-inch transfer case spacers

Warning:

This product is not inclusive in and of itself.

DO NOT attempt to install this product unless you have or will have modified the following components:

a. transfer case slip yoke eliminator kit with constant velocity (CV) type rear drive shaft.

b. body lift - One-inch for 2.5L engines and six-cylinder YJs with automatic transmissions. Two-inch for six-cylinder YJs with manual transmissions.

c. This kit may require longer, “anti-spring-wrap” type purches which will require welding on the axle tube. You must remove your old purches and replace them.

This product does and will effect drive shaft angle and may cause drive shaft vibration.

Installation considerations

Exhaust alignment - Check exhaust alignment and adjust as necessary.

Driveshaft clearance - We recommend allowing at least one inch of clearance for the driveshaft.

Check driveshaft length - If a longer driveshaft is required, Tera offers one inch longer yokes for use with TeraLow driveshafts. Please contact the manufacturer of your driveshaft for longer yokes to fit your application if you don’t already have one.

Shift Linkage Adjustment - Check the shifting linkage and adjust if needed.

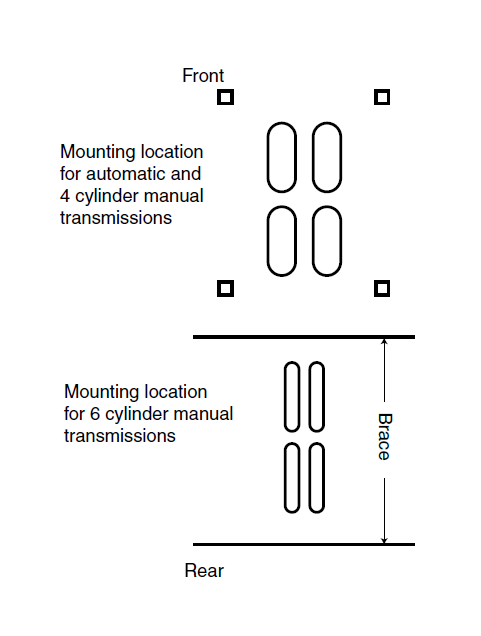

Body Lift - Automatics and four cylinder manuals will need at least a one-inch body lift. Six cylinder manuals will require a two-inch body lift.

Drive shaft vibrations - If drive shaft vibrations occur, adjust axle pinion angle for proper drive shaft angles, and/or shim down the skid plate.

Spring purches - Spring purchases may be needed to correct pinion angles and and must be welded in place. TeraFlex offers longer spring purches for this purpose (Part #PURCH3).

Motor mount spacers - When installing the motor mount spacers, it will be necessary to redrill the hole to accomodate the special nut used on this kit. A 1/2-inch drill bit will be adequate, but a 9/16-inch bit would make installation easier.