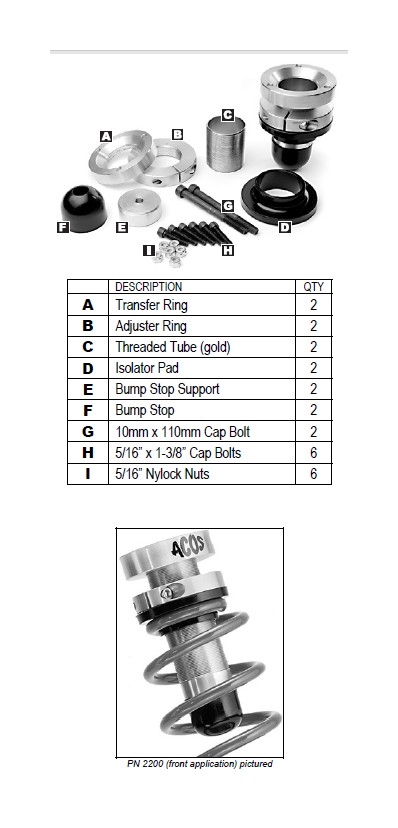

How to Install Zone Offroad Adjustable Rear Coilover Spacer (97-06 Wrangler TJ) on your Jeep Wrangler

Tools Required

- Metric/Standard Socket Wrench Set

- Torque Wrench

- 8mm, 1/4" & 5/16" Allen Wrenches

- Tape Measure

- Medium Strength Threadlocker

- Spray Lubricant (WD-40 or similar)

- Anti-Seize Lubricant

- Hydraulic Floor Jack

- Transfer Punch (or equivalent)

- 1/4" and 3/8" Drill Bits

- Coil Spring Compressor *

- Satin Black Spray Paint *

- Factory Service Manual (recommended)

Shop Parts in this Guide

Welcome

CONGRATULATIONS on your purchase of a new JKS ACOSTM system! At JKS Manufacturing, we are committed to providing you with the best products available and your satisfaction is our first priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain important installation and maintenance information.

Important

MOST VEHICLES REQUIRE additional parts or modifications to accommodate the immediate increase in ride height provided by the ACOS system.

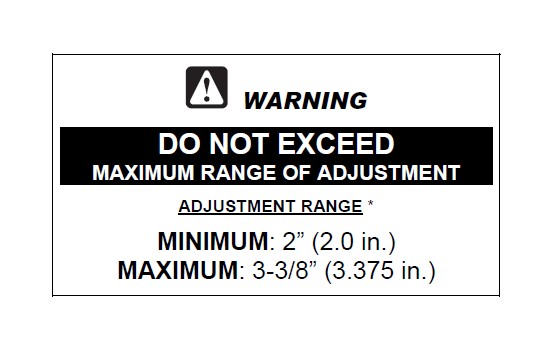

DO NOT EXCEED maximum range of adjustment - see illustration on page 3.

Installation

1. REMOVE REAR COIL SPRINGS

Remove the rear coil springs per the factory service manual instructions for your vehicle. HINT: A coil spring compressor is useful for removal.

Depending on the application, it may be necessary to completely or partially remove any of the following components before spring can be free from upper mount.

• Shock Absorber

• Swaybar

• Track Bar

• Lower Suspension Arm

2. PREPARE UPPER SPRING MOUNT

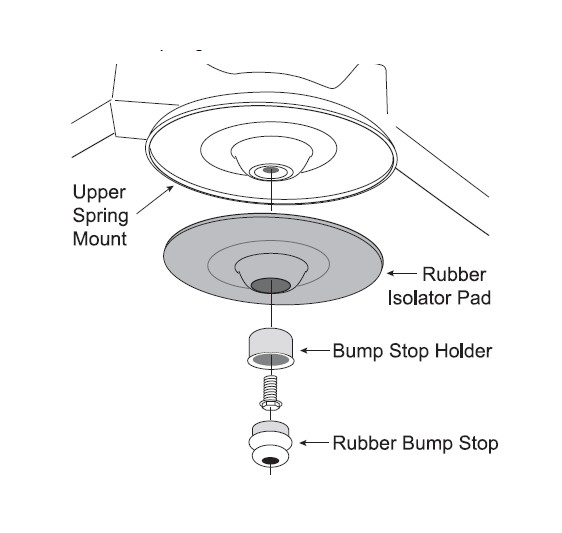

Pry the rubber bump stop (jounce bumper) free from the bump stop holder.

Locate and remove the bolt that secures the bump stop holder to the upper spring mount. Remove the bump stop holder.

Remove the rubber isolator pad from the upper spring mount. Also remove any dirt or debris from the spring mount.

3. DRILL UPPER SPRING MOUNT

Remove the Adjuster Ring (B) and new Isolator Pad (D) from the pre-assembled ACOS unit.

Rotate the Transfer Ring (A) on Threaded Tube (C) until top of Transfer Ring is lust below top edge of tube.

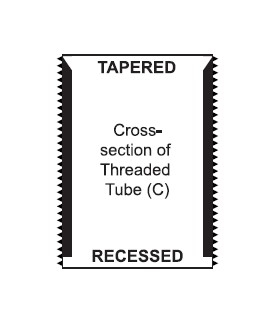

HINT: Threaded Tube (C) is tapered on one end to fit properly against the upper spring mount. Other end of tube is recessed to accommodate the Bump Stop Support (E). Make sure tube orientation is correct!

Position the Threaded Tube (C) with Transfer Ring (A) against the upper spring mount. HINT: Tapered end of Threaded Tube must contact spring mount to ensure Transfer Ring is centered.

Temporarily secure the Threaded Tube (C) with Transfer Ring (A) in place by inserting the 10mm x 110mm Cap Bolt (G) through Bump Stop (F), Bump Stop Support (E), Threaded Tube (C), and then threading into the hole in center of upper spring mount. Bolt should be snug, but do NOT tighten yet.

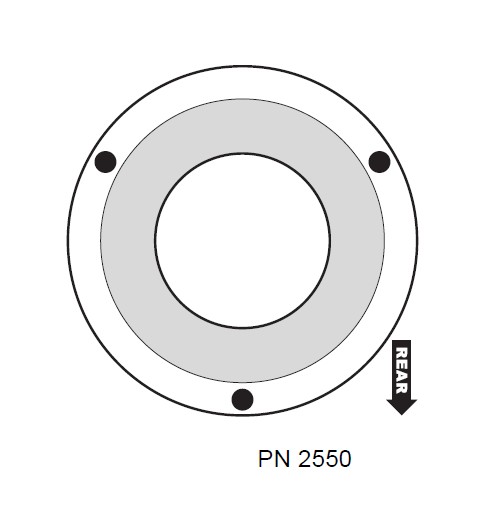

Rotate the Transfer Ring (A) on Threaded Tube (C) until the pre-drilled holes are in the 2-, 6-, and 10-o'clock positions, with the 6-o'clock hole located towards the rear of vehicle. See illustration below.

Mark the hole locations on the upper spring mount using a transfer punch or equivalent. Remove the ACOS components from the upper spring mount.

Using a 1/4" bit, drill a pilot hole at each hole location. Enlarge each hole with a 3/8" drill bit.

Paint any exposed metal on the upper spring mount to prevent corrosion.

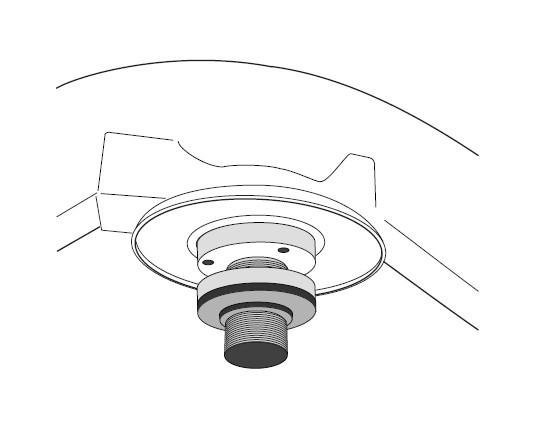

4. INSTALL ACOS ON UPPER SPRING MOUNT

Position the Transfer Ring (A) against the upper spring mount and align the mounting holes.

Insert a 5/16" x 1-3/8" Cap Bolt (H) through each hole and secure with a 5/16" Nylock Nut (I) from above the spring mount. Tighten bolts until snug, then loosen 1/2 turn so that Transfer Ring (A) is slightly movable by hand.

Apply medium strength threadlocker to the upper threads of Threaded Tube (C). Thread tube completely into Transfer Ring (A) until it contacts the upper spring mount. This will center the Transfer Ring on the spring mount.

Next insert the 10mm x 110mm Cap Bolt (G) through the Bump Stop (F) and Bump Stop Support (E), and thread into the hole in the center of the upper spring mount. Bolt should be snug, but NOT fully tightened yet.

Now tighten the 5/16" x 1-3/8" Cap Bolts (H) to 40 ft-lb. using a torque wrench.

IMPORTANT: The Transfer Ring (A) must rest completely flat against the upper spring mount.

Remove the10mm x 110mm Cap Bolt (G), Bump Stop (F), and Bump Stop Support (E) from upper spring mount and re-install Adjuster Ring (B) and Isolator Pad (D) onto the Threaded Tube (C).

Apply anti-seize lubricant to the 10mm x 110mm Cap Bolt (G) and insert through Bump Stop (F) and Bump Stop Support (E). Thread bolt completely into hole in the center of upper spring mount, but do NOT tighten. HINT: Raised surface of Bump Stop Support (E) must face up and fully engage the recessed bottom of Threaded Tube (C).

Slowly tighten 10mm x 110mm Cap Bolt (G) into the coil spring mount until sides of Bump Stop (F) begin to bulge. Do NOT overtighten!

5. SET ADJUSTER RING FOR DESIRED RIDE HEIGHT

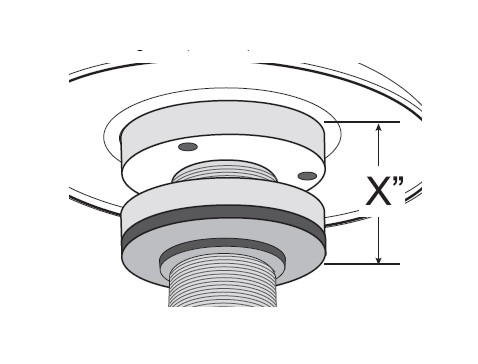

Once the Adjustable Coil Spacer is installed, rear ride height is determined by measuring the distance between top of Transfer Ring (A) and bottom of Isolator Pad (D), and subtracting 1/4" (0.25 in.).

Apply spray lubricant to Threaded Tube (C) and rotate Adjuster Ring (B) to desired position.

Tighten recessed bolt in Adjuster Ring (B) to lock in position.

6. RE-INSTALL REAR COIL SPRINGS

Re-install the rear coil springs per the factory service manual instructions for your vehicle. HINT: A coil spring compressor is useful for installation.

Also re-install any of the components that were removed during the REMOVE REAR COIL SPRINGS step of this installation.

ATTENTION INSTALLER

IMPORTANT NOTE REGARDING SHOCK ABSORBERS

Most vehicles will require additional parts or modifications to accommodate the increase in ride height provided by the ACOS system.

To prevent the coil springs from becoming unseated during maximum suspension extension, correct length shock absorbers must be installed.

Operation

Future ride height adjustments should be made with NO LOAD on the rear coil springs, and the suspension at FULL DROOP.

NEVER turn Adjuster Ring (B) while under tension, and ALWAYS apply spray lubricant to Threaded Tube (C) before adjusting.

Maintenance

Regular cleaning with pressurized water is recommended to maximize ease of operation and reliability.