Guaranteed Free Delivery by 12/24! available on most items - Details

How to Install Zone Offroad Adjustable Front Coilover Spacer (97-06 Wrangler TJ) on your Jeep Wrangler

Tools Required

- Metric/Standard Socket Wrench Set

- 8mm and 5/16” Allen Wrenches

- Tape Measure

- Spray Lubricant (WD-40 or similar)

- Anti-Seize Lubricant

- Hydraulic Floor Jack

- Coil Spring Compressor *

- Die Grinder with Cut-Off Wheel (or Reciprocating Saw) and Grinding Wheel *

- 10mm x 1.5p Tap *

- Satin Black Spray Paint *

- Factory Service Manual (recommended)

Shop Parts in this Guide

Welcome

CONGRATULATIONS on your purchase of a new JKS ACOS™ system! At JKS Manufacturing, we are committed to providing you with the best products available and your satisfaction is our first priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain important installation and maintenance information.

Important

MOST VEHICLES REQUIRE additional parts or modifications to accommodate the immediate increase in ride height provided by the ACOS system.

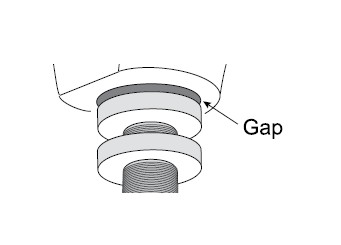

DO NOT EXCEED maximum range of adjustment – see illustration on page 3.

Installation

1. REMOVE FRONT COIL SPRINGS

Remove the front coil springs per the factory service manual instructions for your vehicle. HINT: A coil spring compressor is useful for removal.

Depending on the application, it may be necessary to completely or partially remove any of the following components before spring can be free from upper mount.

• Shock Absorber

• Swaybar

• Brake Line

• ABS Wire

• Lower Suspension Arm

• Track Bar

• Steering Drag Link

• Spring Retainer Clip

2. PREPARE UPPER SPRING MOUNT

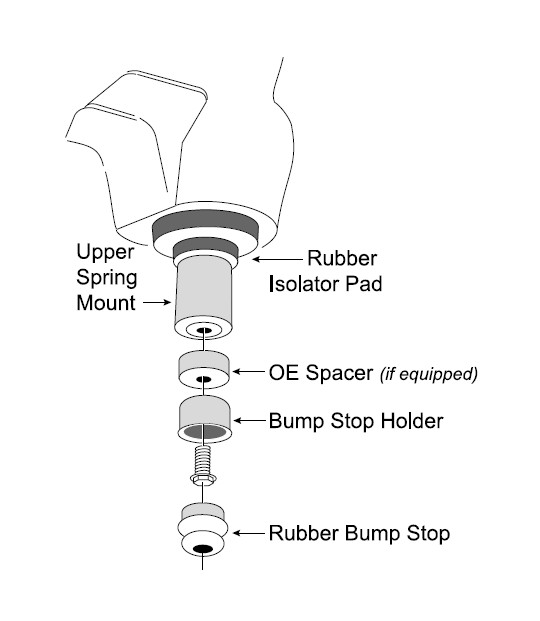

On Wrangler TJ and Grand Cherokee ZJ models, the bump stop holder is secured to the upper spring mount with a single bolt that is accessible once the rubber bump stop is removed.

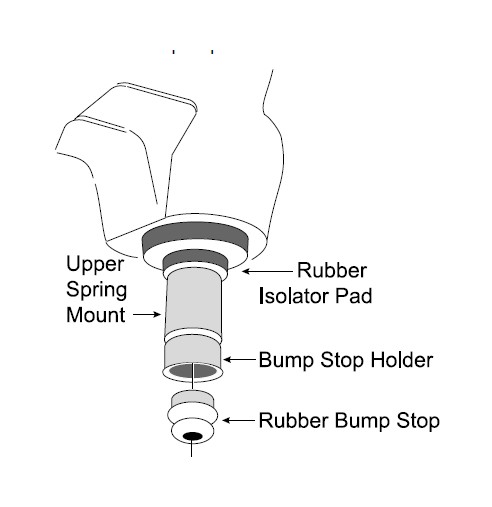

On some Cherokee XJ and Comanchee MJ models, however, the bump stop holder is welded to the spring mount. Specific instructions are provided for vehicles with weld-on bump stop holders.

IMPORTANT: Some Cherokee XJ and Comanchee MJ models utilize welded bump stop holders which must be cut and removed according to the following instructions.

For removal of bolt-on bump stop holder:

Pry the rubber bump stop (jounce bumper) free from the bump stop holder.

Locate and remove the bolt that secures the bump stop holder to the upper spring mount. Remove the bump stop holder and spacer (if equipped) from the upper spring mount.

Remove the rubber isolator pad from the upper spring mount.

For removal of weld-on bump stop holder:

Pry the rubber bump stop (jounce bumper) free from the bump stop holder.

Locate the flat washer that is welded to the spring mount inside the bump stop holder.

Measure the distance between the bottom of flat washer and the lower edge of bump stop holder. Transfer the position of the flat washer to the outside of bump stop holder.

Cut away the lower portion of bump stop holder until even with bottom of flat washer. DO NOT CUT OFF FLAT WASHER! HINT: A die grinder with cutoff wheel or reciprocating saw is useful for cutting bump stop holder.

Grind away any remaining portion of bump stop holder that protrudes beyond flat washer. At the same time, remove any debris from surface of flat washer. HINT: A grinding wheel is useful for removing any additional material or debris.

Insert a 10mm x 1.5p tap straight into the flat washer to form a threaded hole. The hole in flat washer should be the correct size. If not, enlarge the hole according to the size indicated on the tap.

Remove the rubber isolator pad from the upper spring mount.

Paint any exposed metal to prevent corrosion.

3. INSTALL ACOS ON SPRING MOUNT

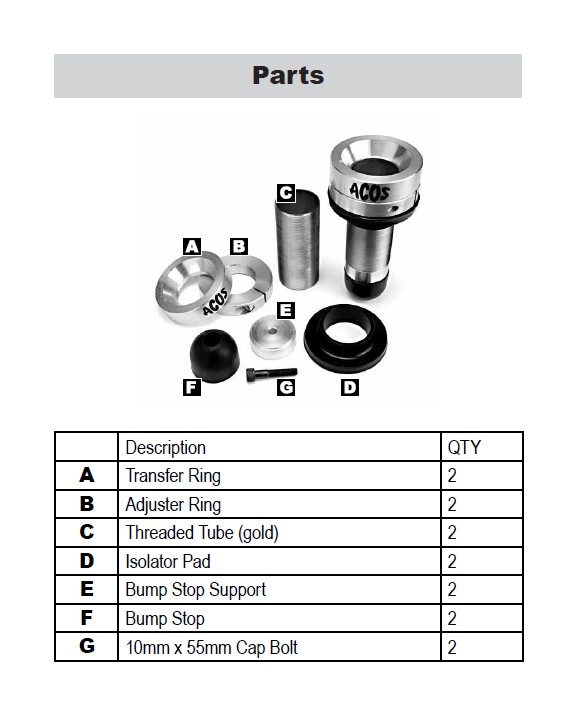

Rotate the Transfer Ring (A) until inner threads are even with top edge of Threaded Tube (C).

Slide the pre-assembled ACOS unit all the way on to the upper spring mount. If necessary, remove any debris or obstructions that prevent Threaded Tube (C) from seating cleanly against top surface of upper spring mount.

HINT: Transfer Ring (A) should not make contact with upper spring mount at this time. If necessary, adjust Transfer Ring away from top surface of spring mount.

Apply anti-seize lubricant to the 10mm x 55mm Cap Bolt (G) and insert through Bump Stop (F) and Bump Stop Support (E). Thread bolt completely into hole in the center of upper spring mount, but do NOT tighten. HINT: Raised surface of Bump Stop Support (E) must face up and fully engage bottom of Threaded Tube (C).

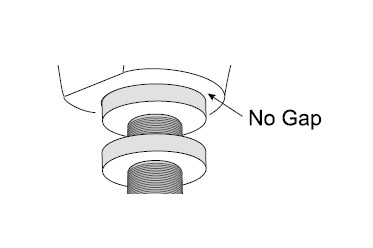

Now rotate the Transfer Ring (A) up until it contacts the flat surface above it.

Unthread the 10mm x 55mm Cap Bolt (G) a few turns so Threaded Tube (C) can be lowered slightly. Then rotate the Transfer Ring (A) one-half turn up towards flat surface above.

Slowly tighten 10mm x 55mm Cap Bolt (G) into the coil spring mount until sides of Bump Stop (F) begin to bulge. Do NOT overtighten!

4. SET ADJUSTER RING FOR DESIRED RIDE HEIGHT

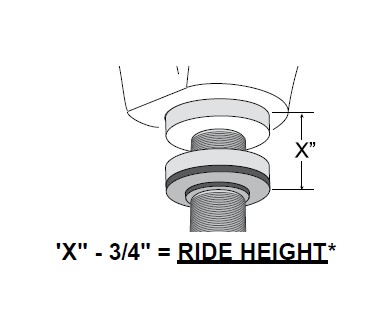

Once the Adjustable Coil Spacer is installed, front ride height is determined by measuring the distance between top of Transfer Ring (A) and bottom of Isolator Pad (D), and subtracting 3/4” (0.75 in.).

Apply spray lubricant to Threaded Tube (C) and rotate Adjuster Ring (B) to desired position.

Tighten recessed bolt in Adjuster Ring (B) to lock in position.

5. RE-INSTALL FRONT COIL SPRINGS

Re-install the front coil springs per the factory service manual instructions for your vehicle. HINT: A coil spring compressor is useful for installation.

Also re-install any of the components that were removed during the REMOVE FRONT COIL SPRINGS step of this installation.

ATTENTION INSTALLER

IMPORTANT NOTE REGARDING SHOCK ABSORBERS

Most vehicles will require additional parts or modifications to accommodate the increase in ride height provided by the ACOS system.

To prevent the coil springs from becoming unseated during maximum suspension extension, correct length shock absorbers must be installed.

Operation

Future ride height adjustments should be made with NO LOAD on the front coil springs, and the suspension at FULL DROOP.

NEVER turn Adjuster Ring (B) while under tension, and ALWAYS apply spray lubricant to Threaded Tube (C) before adjusting.

Maintenance

Regular cleaning with pressurized water is recommended to maximize ease of operation and reliability.