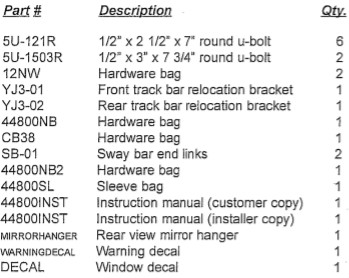

How to Install Tuff Country 3.5 in. Suspension Lift Kit w/ Shocks (87-95 Wrangler YJ) on your Jeep Wrangler

Tools Required

- Torque wrench

- Standard socket set

- Standard wrench set

- Metric socket set

- Metric wrench set

- Tape measure

- Hydraulic floor jacks

Congratulations on your selection 'to purchase a Tuff Country .EZ-Ride Suspension System. We at Tuff Country EZ-Ride Suspension are proud to offer a high quality product at the industries most competitive pricing. Thank you for your confidence in us and our product.

For a list of parts, please refer to the last page of the installation manual.

Make sure to use thread locker or lock tite on all new and stock hardware associated with the installation of this suspension system.

It is the responsibility of the installers or the retail shop'

to make sure that the customer receives a copy of the installation manual and the warning pamphlets. Tuff Country sends (2) copies of the installation manual. One for the installer and one for the customer that has proper post installation procedures.

After the completion of the installation a front end alignment is required.

Important customer information:

Tuff Country EZ-Ride Suspension highly recommends that a qualified or a certified mechanic performs this installation.

It is the responsibility of the customer or the mechanic to wear safety glasses at all times when performing this installation.

It is the customers or the installers responsibility to read and understand all steps before installation begins. If you have any questions or concerns, please contact our technical department @ (801) 280-2777. Also, the OEM manual should be used as a reference guide.

This vehicles reaction and handling characteristics may differ from standard cars and/or trucks. Modifications to improve and/or enhance off road performance may raise the intended center of gravity. Extreme caution must be utilized when encountering driving conditions which may cause vehicle imbalance or loss of control. DRIVE SAFELY! Avoid abrupt maneuvers: such as sudden sharp turns which could cause a roll over, resulting in serious injury or death.

It is the customers responsibility to make sure that a re-torque is performed on all hardware associated with this suspension system after the first 100 miles of installation. It is also the customers responsibility to do a complete re-torque after every 3000 miles or after every off road use.

After the original installation, Tuff Country EZ-Ride Suspension also recommends having the alignment checked every 6 months to ensure proper tracking, proper wear on tires and front end components. Tuff Country EZ-Ride Suspension takes no responsibility for abuse, improper installation or improper suspension maintenance.

If you desire to return your vehicle to stock, it is the customers responsibility to save all stock hardware.

The Tuff Country EZ-Ride Suspension product safety label that is included in your kit box must be installed inside the cab in plain view of all occupants.

Special note: Before installation begins, it is the customers/installers responsibility to make sure that all parts are on hand. If any parts are missing, please feel free to call one of our customer service representatives @ (801) 280-2777.

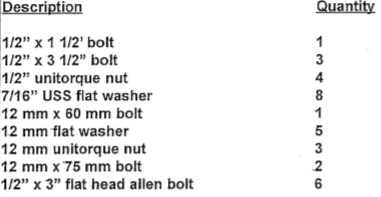

Hardware bag 44800NB includes:

Hardware bag 44800NB2 includes:

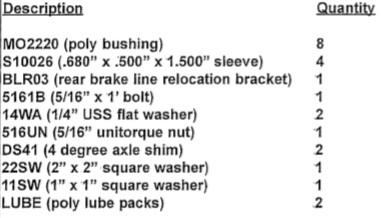

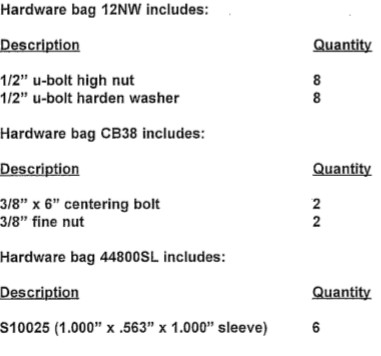

Hardware bag 12NW includes:

Please follow instructions carefully:

Before installation begins, measure from the center of the hub, to the bottom of the fender well, and record measurements below.

Front end installation:

1. To begin installation, block the rear tires of the vehicle so that the vehicle is stable and can not roll backwards. Safely lift the front of the vehicle and support the frame with a pair of jack stands. Place one on the driver side and one on the passenger side. Next, remove the tires and wheels from the front of the vehicle.

2. Working on the driver side, remove the stock hardware from the stock upper stem mount on the stock shock and discard the stock hardware. Next, remove the lower stock mounting hardware that connects the stock shock to the stock location. Save the stock hardware. The stock shock may be discarded. Special note: New longer front shocks are needed after this suspension system has been installed and the front shocks need to be ordered as a separate part -#. If you have not already ordered your front shocks, please feel free to contact Tuff Country or your local Tuff Country dealer and order your front shocks. Tuff Country recommends installing a 30" fully extended cellular gas shock in the front. Repeat procedure on the passenger side.

3. Working on the driver side, remove the stock sway bar end link from the stock lower location and save the stock hardware. Now remove the stock upper mounting hardware that connects the stock sway bar end link to the stock sway bar. The stock end link and the stock upper mounting hardware may be discarded. Repeat procedure on the passenger side.

4. Working on the driver side, remove the stock brake line from the stock mounting location and save the stock hardware. Repeat procedure on the passenger side.

5. Place a pair of hydraulic floor jacks under the front axle. Place one on the driver side and one on the passenger side. Carefully raise up on both hydraulic floor jacks at the same time until they come into contact with the front axle.

6. Working on the passenger side, remove the stock track bar from the stock location, save the stock hardware for later re-installation. Let the stock track bar hang.

7. Working on the driver side, remove the stock tie rod that connects to the stock pitman arm. Save the stock hardware for later re-installation. Carefully break the stock tapper on the stock tie rod and the stock pitman. Special note: take special care not to damage the stock tie rod boot. Next, remove the stock sector shaft hardware holding the stock pitman arm to the stock sector shaft. Save the stock hardware for later re-installation. With a pitman arm puller, carefully remove the stock pitman arm from the stock sector shaft. The stock pitman arm may be discarded. Special note: The pitman arm needs to be ordered as a sperate part # from the box kit. If you have not already ordered your new pitman arm, please contact Tuff Country or your local Tuff Country dealer and order (1) 70401 (old part # YJSA).

8. Working on the driver side, remove the stock u-bolts from the stock location. The stock u-bolts and the stock hardware may be discarded. Set the stock u-bolt plate aside for later re-installation. Repeat procedure on the passenger side.

9. Working on the driver side, remove the stock spring from the stock front and rear location. The stock spring may be discarded. Save the stock mounting hardware for later reinstallation.

10. Locate the new front springs. Special note: The new front springs need to be ordered as a sperate part # from the box kit. If you have not already ordered your new front springs, please contact Tuff Country or your local Tuff Country dealer and order (2) 48380 (old number TCIYJ3F). Remove the new bushings and sleeves from the new front spring pack. Using some lithium or moly base grease, spread a fair amount of grease onto the new bushings and re-install the bushings and sleeves back into the new front springs. Special note: Using the lithium or moly base grease will help on performance of the springs, the life of the bushings as well as help prevent squeaking.

11. Locate the stock spring mounting hardware that was removed in step # 9. Working on the driver side, install the new front spring into the stock location. Add some thread locker or lock tite and torque the spring hanger hardware (rear eyelet) to 90 ft. lbs. Special note: Do not tighten the spring shackle hardware. We will do this, once the weight of the vehicle is on the ground. Repeat procedure on the passenger side.

12. Carefully lower down on both hydraulic floor jacks holding the front axle at the same time until the front axle perch seats properly with the newly installed front springs.

13. Locate (2) 1/2" x 2 1/2" x 7" round u-bolts. Locate (4) 1/2" u-bolt high nuts and (4) 1/2" u-bolt harden washers from hardware bag 12NW. Also, locate the stock u-bolt plate that was removed from step # 8. Working on the driver side, install the new u-bolts into the stock location and secure using the new u-bolts, hardware and stock u-bolt plate. Torque the new u-bolts to 85 ft lbs.

14. Locate (2) 1/2" x 3" x 7 3/4" round u-bolts. Locate (4) 1/2" u-bolt high nuts and (4) 1/2" u-bolt harden washers from hardware bag 12NW. Also, locate the stock u-bolt plate that was removed in step # 8. Working on the passenger side, install the new u-bolts into the stock location and secure using the new u-bolts, hardware and stock u-bolt plate. Torque to new u-bolts to 85 ft lbs.

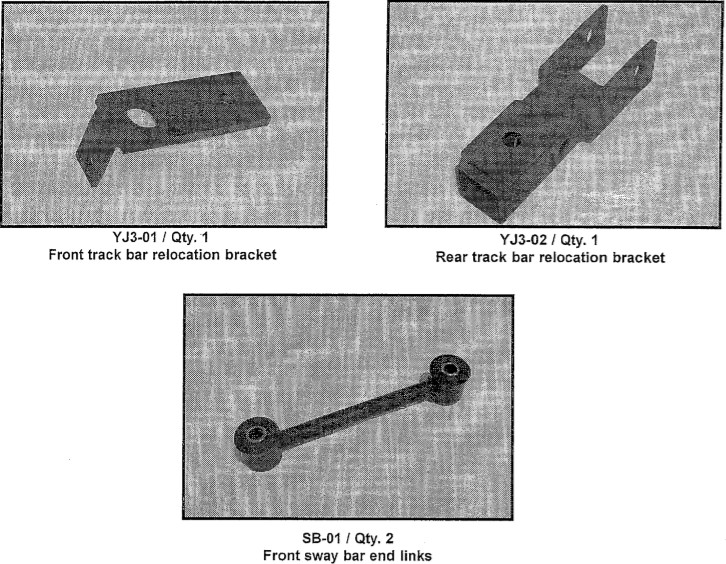

15. Locate the new front sway bar end links. Locate (8) M02220 (poly bushings), and (4) S10026 (sleeves) from hardware bag 44800NB2. Install the new bushings and sleeves into each end of the new end links. Special note: Make sure to use a lithium or moly base grease prior to inserting the new bushings and sleeves into the new end links. This will help increase the life of the bushings, help prevent squeaking and allow the new end links t work properly.

16. Locate (2) 1/2" x 3 1/2" bolts, (4) 7/16" USS flat washers and (2) 1/2" unitorque nuts from hardware bag 44800NB. Working on the driver side, install The new end link to the stock sway bar and secure using the new 1/2" x 3 1/2" bolt and hardware. Do not tighten at this point. Repeat procedure on the passenger side.

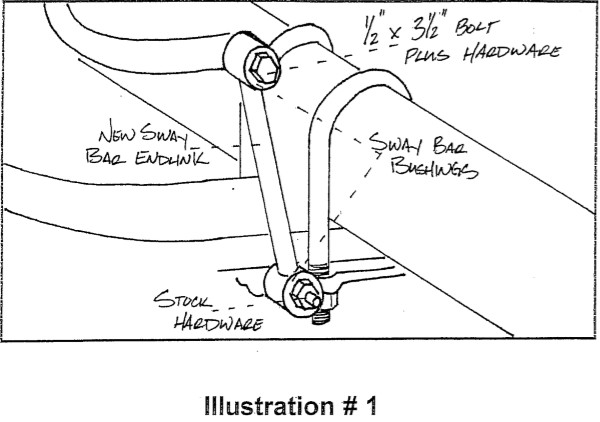

Illustration # 1

17. Locate the front stock lower end link hardware that was removed from step # 3. Working on the driver side, secure the new end link to the stock lower u-bolt plate and secure using the stock hardware. Make sure to use thread locker or tite and torque to 50 ft lbs. Repeat procedure on the passenger side. Move back to the new hardware that was installed in step# 15, attaching the new end links to the stock sway bar and add some thread locker or lock-tite and torque the new 1/2" hardware to 80 ft lbs.

18. Carefully remove the hydraulic floor jacks from under the front axle.

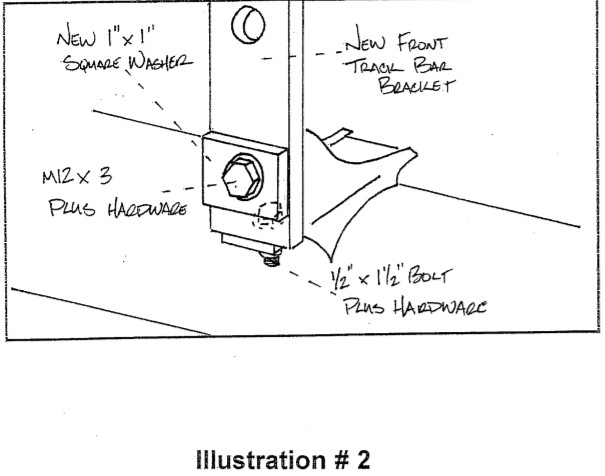

19. Locate the new front track bar relocation bracket. Locate (1) 12 mm x 60 mm bolt, (2) 12 mm flat washers and (1) 12 mm unitorque nut from hardware bag 44800NB. Also, locate (1) 1" x 1" square washer from hardware bag 44800NB2. Working on the passenger side, install the new front track bar relocation bracket around the outside of the stock location and secure using the new 12 mm x 60 mm bolt and hardware. Special note: the -1" x 1" square washer will be installed on the outside of the new track bar relocation bracket.

Illustration # 2

20. Using the newly installed front track bar relocation bracket as a guide, carefully drill a 1/2" hole into the bottom of the stock track bar location.

21. Locate (1) 1/2" x 1 1/2" bolt, (2) 7/16" USS flat washers and (1) 1/2" unitorque nuts. Move back to the new front track bar relocation bracket that was installed in step # 19 and remove the newly installed 12 mm hardware. Set the new 12 mm bolt, hardware and 1" x 1" square washer aside. Secure the new front track bar relocation bracket to the stock mounting point using the new 1/2" x 1 1/2" bolt and hardware into the previously drill hole. Make sure to add some thread locker or lock tite and torque to 80 ft lbs. Now re-install the new 12 mm bolt, hardware and 1" x 1' square washer that was moved earlier in this step. Make sure to add some thread locker or lock tite and torque to 65 ft lbs.

Illustration # 2

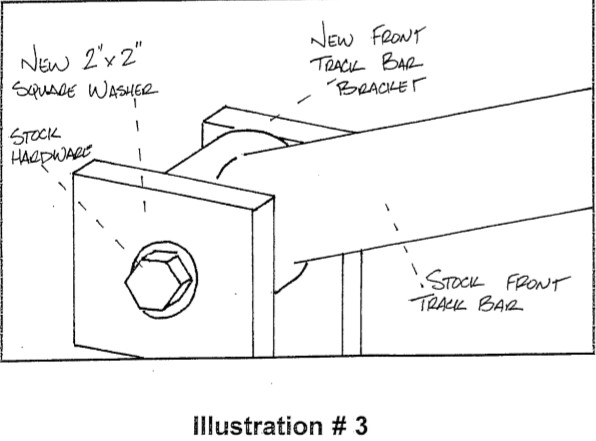

22. Locate (1) 2" x 2" square washer from hardware from hardware bag 44800NB2. Also, locate the stock front track bar hardware that was removed in step # 6. Install the stock track bar to the newly installed track bar relocation bracket and secure using the stock hardware and the new 2" x.2" square washer. Make sure to add some thread locker or lock tite and torque the stock hardware to 65 ft lbs. Special note: The new 2"x 2" square washer will be installed to the front of the stock track bar. Also, if you are not able to install the stock track bar to the newly installed track bar relocation bracket, this step will need to be performed once the weight of the vehicle is on-the ground.

Illustration #:3

23. Working on the driver side, carefully drill a 5/16" hole into the front portion of the stock upper shock mount. Repeat procedure on the passenger side.

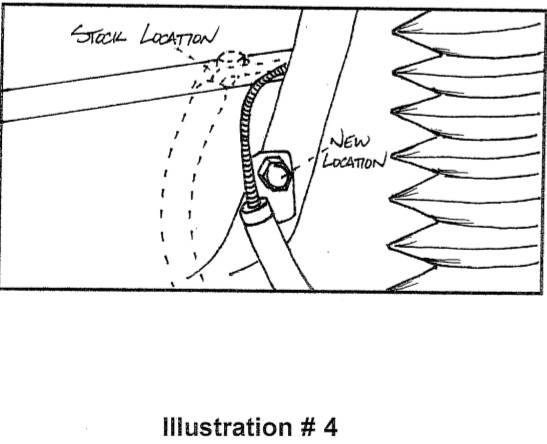

24. Locate the stock brake line mounting hardware that was removed in step # 4. Working on the driver side, secure the stock brake line into the new location and secure using the stock hardware. Make sure to use thread locker or lock tite and torque to 18 ft lbs. Repeat procedure on the passenger side. Special note: Carefully bending of the stock hard line will make installation easier. Take special care not to over extend or break the stock hard line.

Illustration* 4

25. Locate the new front shocks. Special note: New longer front shocks are needed after this suspension system has been installed and the front shocks need to be ordered as a separate part #. If you have not already ordered your front shocks, please feel free to contact Tuff Country or your local Tuff Country dealer and order your front shocks. Tuff Country recommends installing a 30" fully extended cellular gas shock in the front. Locate the new poly bushings and proper sleeve from the hardware bag supplied with the new front shocks and install the new poly bushings and crush sleeve into the bottom part of the new shock. Special note: Make sure to use a lithium or moly base grease prior to inserting the new bushings and sleeves into the new lower eyelet of the new shock. This will increase the life of the bushing as well as prevent squeaking.

26. Locate the stock lower mounting shock hardware that was removed in step # 2. Working on the driver side, install the new shock into the stock lower mounting location and secure using the stock hardware. Make sure to add thread locker or lock tite and torque the lower mounting hardware to 60 ft lbs. Secure the upper stem of the new shock into the stock location and secure using the new hardware provided with the new shock. Make sure to add some thread locker or lock tite and torque to 18 ft lbs. Special note: Tuff Country EZ-Ride Suspension highly recommends that the shocks are installed with shock boots. If shock boots are not installed, damaged my occur to the piston of the new shock. Repeat procedure on the passenger side.

27. Locate the new pitman arm. Special note: The pitman arm needs to be ordered as a sperate part # from the box kit. If you have not already ordered your new pitman arm, please contact Tuff Country or your local Tuff Country dealer and order (1) 70401 (old part -# YJSA). Locate the stock sector shaft hardware and the stock tie rod hardware that was removed in step # 7. Install the new pitman arm to the stock sector shaft and secure using the stock hardware. Make sure to use thread locker or lock tite and torque to 145 ft lbs. Next, install the tie rod to the newly installed pitman arm and secure using the stock hardware. Torque to 85 ft lbs.

28. Check and double check to make sure that steps were performed properly with the front end.

29. Install the tires and wheels and carefully lower the vehicle to the ground.

30. If you were not able to install the stock track bar into the newly installed track bar relocation bracket in step #22, perform step # 22 now that the weight of the vehicle is on the ground.

Special note: If the vehicle that you are working on is equipped with a automatic transmission, please follow step # 31

Special note: If the vehicle that you are working on is not equipped with an automatic transmission, please skip to step # 32

31. Locate the new rear springs. Locate (2) new 4 degree axle shims from hardware bag 44800NB2. Also, locate (2) 3/8" x 6" center bolts and (2) 3/8" fine nuts from hardware bag CB38. Working on the rear springs and using a pair of clamps, place the clamps on both side of the axle shim that is attached to the new rear spring. Carefully remove the centering bolt and nut holding the axle shim to the new rear springs. The centering bolt, nut and axle shim may be discard. Next, install the new 4 degree shims to the new rear springs and secure using the new 3/8" centering bolt and nuts. Torque the new hardware to 40 ft lbs. With a suitable cutting tool, carefully cut off the excess thread off the centering bolt. Special note: Make sure that when you installed the new 4 degree shim that the thicker part of the shim is installed towards the transfer case.

32. To begin installation, block the front tires of the vehicle so that the vehicle is stable and can not roll forward. Safely lift the rear of the vehicle and support the frame with a pair of jack stands. Place one on the driver side and one on the passenger side. Next, remove the tires and wheels from the rear of the vehicle.

33. Working on the driver side, remove the stock shock from the stock upper and lower mounting location. Save the stock mounting hardware. The stock shock may be discarded. Special note: New longer rear shocks are needed after this suspension system has been installed and the rear shocks need to be ordered as a separate part #. If you have not already ordered your rear shocks, please feel free to contact Tuff Country or your local Tuff Country dealer and order your rear shocks. Tuff Country recommends installing a 23" fully extended cellular gas shock in the rear. Repeat procedure on the passenger side.

34. Place a pair of hydraulic floor jacks under the rear axle. Place one on the driver side and one on the passenger side. Carefully raise up on both hydraulic floor jacks until they make contact with the rear axle.

35. Working on the driver side, remove the stock track bar from the stock track bar mounting location. Save the stock hardware. Also at this time, remove the stock inner plate that is located inside the stock track bar pocket and discard.

36. Working on the driver side, remove the stock brake line from the stock brake line bracket. Special note: Brake fluid will leak out, use something to catch the brake fluid as it leaks out. Also, once the installation is complete, the brake lines are going to have to be bleed and proper brake fluid is going to need to be added.

37. Working on the driver side, remove the stock u-bolts from the stock location. The stock u-bolts and hardware may be discarded. Save the stock u-bolt plate for later re-installation. Repeat procedure on the passenger side.

38. Working on the driver side, remove the stock spring from the stock spring hanger and the stock shackle. Save the stock hardware-for later re-installation. The stock spring may be discarded. Repeat procedure on the passenger side.

39. Locate the new rear springs. Special note: The new rear springs need to be ordered as a sperate part # from the box kit. If you have not already ordered your new rear springs, please contact Tuff Country or your local Tuff Country dealer and order (2) 49380 (old number TCIYJ3R). Remove the new bushings and sleeves from the new rear spring pack. Using some lithium or moly base grease, spread a fair amount of grease onto the new bushings and re-install the bushings and sleeves back into the new rear springs. Special note: Using the lithium or moly base grease will help on performance of the springs, the life of the bushings as well as help prevent squeaking.

40. Locate the stock spring hardware that was removed in step # 38. Working on the driver side, install the new spring into the stock location and secure using the stock hardware. Add some thread locker or lock tite to the spring hanger hardware and torque to 90 ft lbs. Special note: Do not tighten the spring shackle hardware. We will do this, once the weight of the vehicle is on the ground. Repeat procedure on the passenger side.

41. Carefully lower down on both hydraulic floor jacks holding the rear axle at the same time until the rear axle perch seats properly with the newly installed rear springs.

42. Locate (4) 1/2" x 2 1/2" x 7" round u-bolts. Locate (8) 1/2" u-bolt high nuts and (8) 1/2" u-bolt harden washers from hardware bag 12NW. Also, locate the stock u-bolt plate that was removed from step # 37. Working on the driver side, install the new u-bolts into the stock location and secure using the new u-bolts, hardware and stock u-bolt plate. Torque the new u-bolts to 85 ft lbs. Repeat procedure on the passenger side.

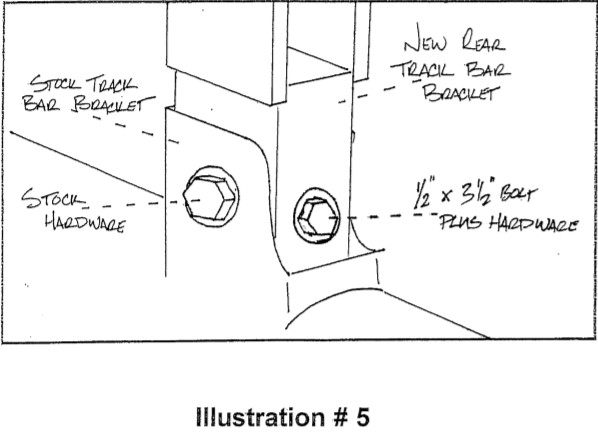

43. . Locate the new rear track bar relocation bracket. Locate the stock track bar mounting hardware that was removed in step # 35. also, locate (1) 1/2" x 3 1/2" bolt, (2) 7/16" USS flat washers and (1) 1/2" unitorque nut from hardware bag 44800NB. Working on the driver side, slide the new track bar relocation bracket into the stock track bar pocket. Special note: Make sure that the washer that is welded on to the side of the new bracket is installed towards the driver side of the vehicle once the new track bar relocation bracket is installed into the stock pocket. Secure the new bracket to the stock pocket using the stock hardware. Do not tighten at this point. Using the new rear track bar bracket as a guide, carefully drill a 1/2" hole into the stock bracket and secure using the new 1/2" x 3 1/2" bolt and hardware. Make sure to use thread locker or lock tite and torque to 75 ft lbs. Now more back to the stock hardware holding the new track bar relocation bracket to the stock location and add some thread locker or lock tite and torque to 75 ft lbs.

Illustration # 5

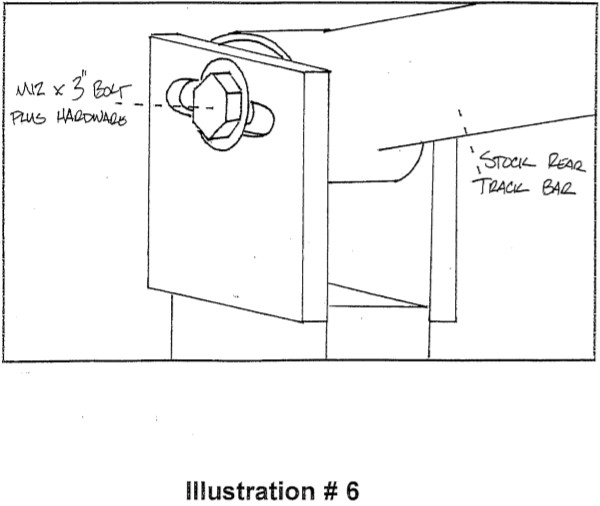

44. Locate (1) 12 mm x 75 mm bolt, (2) 12 mm flat washers and (1) 12 mm unitorque nut from hardware bag 44800NB. Install the stock track bar to the newly installed track bar relocation bracket and secure using the new 12 mm x 75 mm bolt and hardware. Make sure to use some thread locker or lock tite and torque to 75 ft lbs. Special note: If you are not able to install the stock track bar to the newly installed track bar relocation bracket, this step may need to be performed once the weight of the vehicle is on the ground.

Illustration # 6

45. Locate (1) BLR03, (1) 5/16".x 1" bolt, (2) 1/4" USS flat washers and (1) 5/16" unitorque nut from hardware bag 44800NB2. Install the new brake line relocation bracket to the stock location and secure using the new 5/16" x 1' bolt and hardware. Make sure to use thread locker or lock tite and torque to 12 ft lbs. Next, install the stock brake line to the newly installed brake line relocation bracket.

46. Locate the new rear shocks. Special note: New longer rear shocks are needed after this suspension system has been installed and the rear shocks need to be ordered as a separate part #. If you have not already ordered your rear shocks, please feel free to contact Tuff Country or your local Tuff Country dealer and order your rear shocks. Tuff Country recommends installing a 23" fully extended cellular gas shock in the rear. Locate the new poly bushings and proper sleeves from the hardware bag supplied with the new rear shocks and install the new poly bushings and crush sleeve into the top and bottom part of the new shock. Special note: Make sure to use a lithium or moly base grease prior to inserting the new bushings and sleeves into the new lower eyelet of the new shock. This will increase the life of the bushing as well as prevent squeaking.

47. Locate the stock upper and lower shock mounting hardware that was removed in step # 35. Working on the driver side, install the new shock into the stock location and secure using the stock hardware. Make sure to use thread locker or lock tite and torque the stock upper and lower mounting hardware to 80 ft lbs. Special note: Tuff Country EZ-Ride Suspension highly recommends that the shocks are installed with shock boots. If shock boots are not installed, damaged my occur to the piston of the new shock. Repeat procedure on the passenger side.

48. Carefully remove the hydraulic floor jacks from under the rear differential.

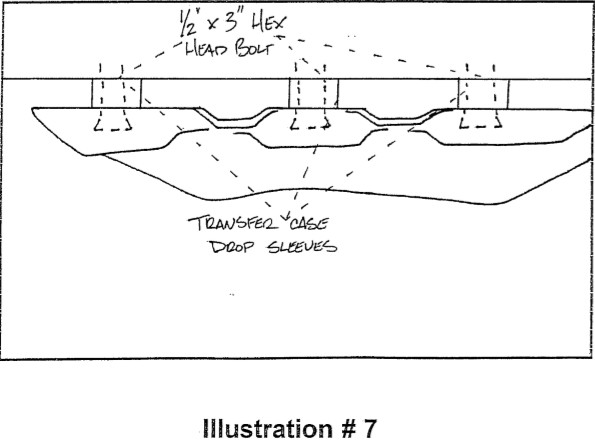

49. Place a hydraulic floor jack under the transfer case cross member. Working on the driver side, remove the (3) stock bolts holding the stock transfer case cross member to the stock frame rail. The stock hardware may be discarded. Repeat procedure on the passenger side.

50. Locate (6) S10025 transfer case lowering sleeves from hardware bag 44800SL. Also, locate (6) 1/2" x 3" flat head alien bolts from hardware bag 44800NB. Working on the driver side, install (3) transfer case lowering sleeves between the stock transfer case cross member and the stock frame rail and secure using the new 1/2" x 3" flat head alien bolts. Make sure to use thread locker or lock tight. Repeat procedure on the passenger side. Torque the new 1/2" x 3" alien head alien bolts to 85 ft lbs. Special note: Tuff Country highly recommends NOT using a air gun when installing the new 1/2" x 3" flat head alien bolts, if an air gun is used the bolt may strip in the frame of the vehicle. Illustration # 7

51. Carefully remove the hydraulic floor jack from under the transfer case cross member.

52. Install the tire and wheels and carefully lower the vehicle to the ground. 53. If you were not able to install the stock track bar to the newly installed track bar relocation bracket in step # 44, perform this step now that the weight of the vehicle is on the ground. 54. With the help from a buddy, carefully bleed the stock brake lines. Also, make sure to fill the brake fluid reservoir with proper brake fluid. 55. Check and double check to make sure that all steps were performed properly and check again.

Congratulations, installation complete!

Special note: After the completion of the installation, Tuff Country EZ-Ride Suspension recommends taking the vehicle to an alignment shop and having a proper front end alignment performed.

Tuff Country EZ-Ride Suspension recommends that a complete re-torque is done on all bolts associated with this suspension system. It is the customers responsibility to make sure that a re-torque is performed on all hardware associated with this suspension system after the first 100 miles of installation. It is also the customers responsibility to do a complete re-torque after every 3000 miles or after every off road use. Neglect of following these steps could cause brackets to come loose and cause serious damage to the suspension system and to the vehicle.

Tuff Country EZ-Ride Suspension packages (2) sets of instruction sheets with this box kit. (1) is for the installer and (1) is for the customer. The (1) for the customer has some post installation procedure literature and it is the installers responsibility to make sure that the customer receives a copy of the installation manual along with the literature.

If you have any questions or concerns, please feel free to contact Tuff Country or your local Tuff Country dealer.