How to Install Teraflex 2.5 in. Lift Kit w/ adapters for shocks on your Wrangler

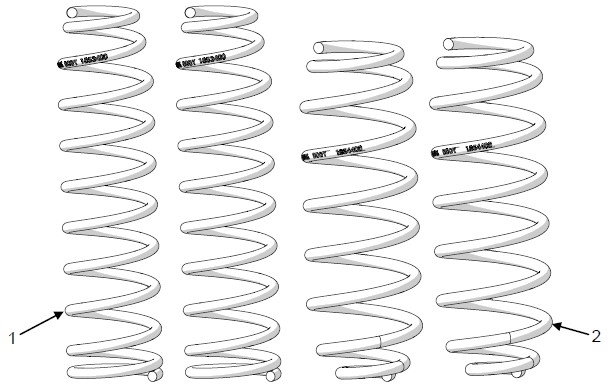

Contents:

Rear Sway Bar Link Instructions

Spring Instructions

Bumpstop Instructions

Rear Lower Spring Retainer Instructions

Rear Brake Line Extension Bracket Instructions

This packet may not include all necessary instruction sets for your lift kit. Check every received box for additional instruction sets.

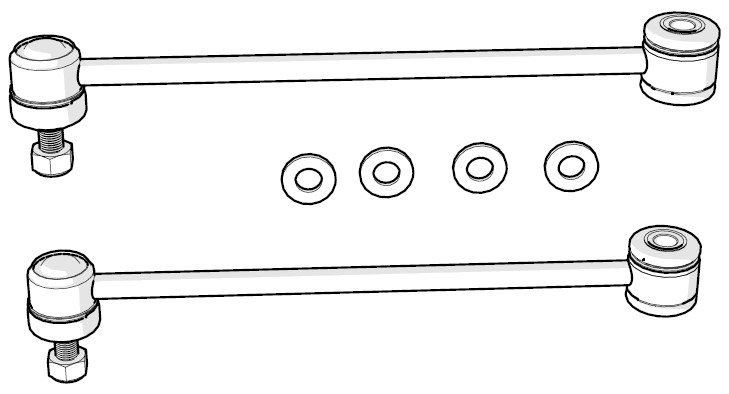

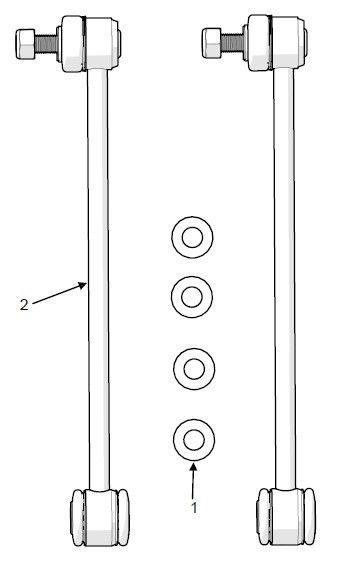

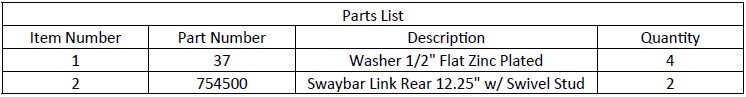

JK 3”-4” Rear Swivel Stud Swaybar Link Kit

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

1. Park the vehicle on a level surface and chock the front tires. Break the rear lug nuts loose with the vehicle on the ground but do not remove the nuts completely. Jack the rear of the vehicle off the ground and lower it onto jack stands. Remove the wheels.

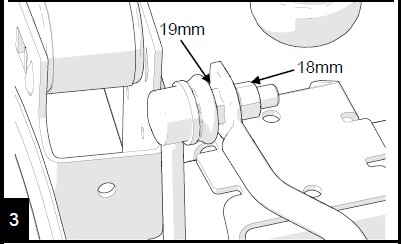

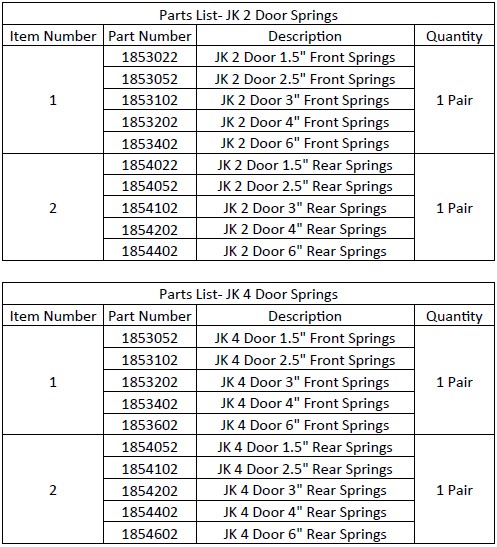

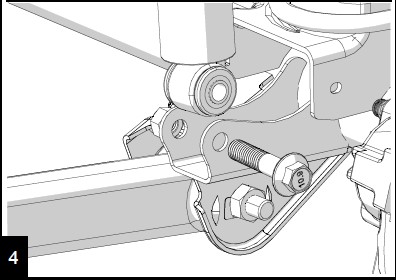

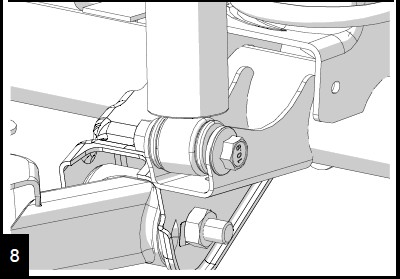

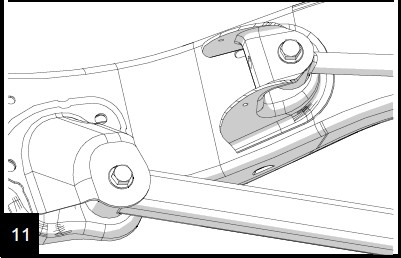

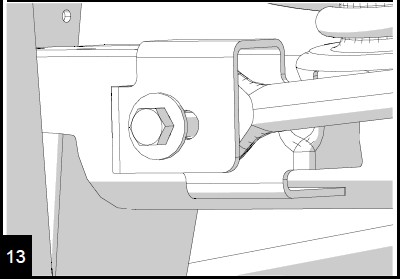

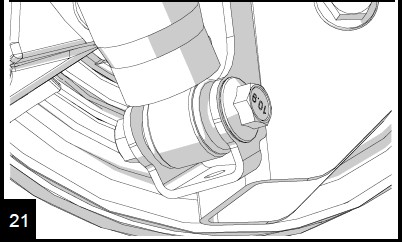

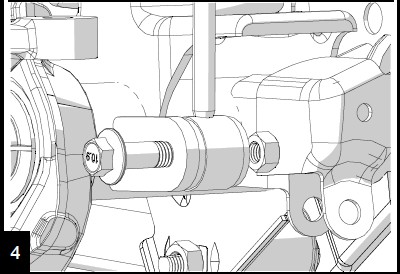

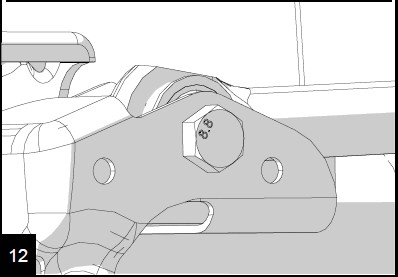

2. Using the 18mm socket and wrench, remove the bolt holding the factory link to the axle bracket.

Using a 19mm wrench to hold the stud from turning and an 18mm to remove the nut, remove the link form the swaybar. Repeat steps 2 and 3 on other side.

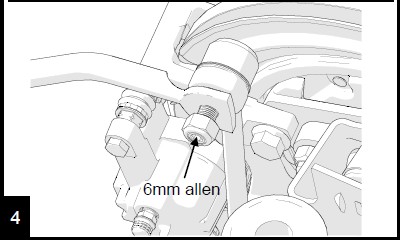

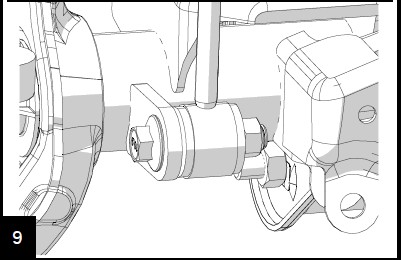

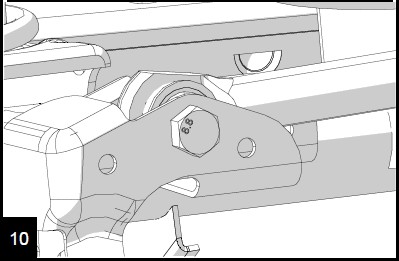

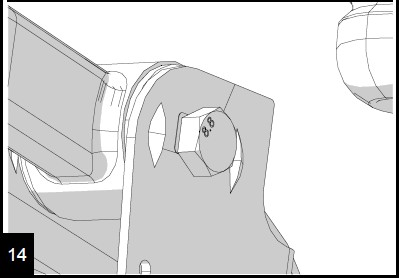

With both factory links removed, install the swivel end of the link into the swaybar from the outside. Install the new lock nut using the 19mm end wrench and the 6mm allen wrench. Torque to 66 ft-lbs

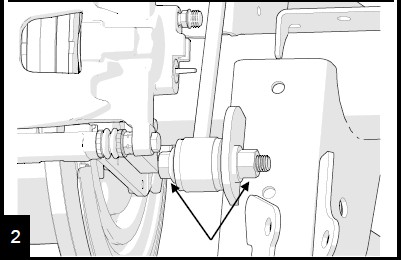

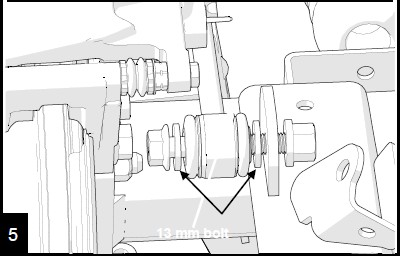

5. Using the 18mm install the factory hardware and two provid-ed washers on the lower end of the link. Place the washers on either side of the bushing. Torque to 75 ft-lbs.

6. Replace the wheels, torque to 110 ft-lbs. Raise off the jack stands, lower to the ground and remove the chocks.

JK Spring Removal and Installation

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

This product will change the highway handling characteristics of your vehicle, exercise caution.

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

FRONT REMOVAL

1. Refer to the factory service manual for lift locations. Raise and support the vehicle. Remove the tires and wheels and support the axle with a jack or jack stands.

2. Remove the track bar at the axle with a 21mm. The nut is a flag nut. (See 999208 Front Track Bar/Removal)

Loosen all front control arm bolts with a 21mm. DO NOT REMOVE ARMS OR BOLTS.

Remove the shocks at the axle with an 18mm wrench and socket. (See 999207 Shocks/Front/Removal)

Remove the sway bar links with an 18mm wrench and socket at the axle. If you are replacing the links, remove completely. (See 999027 Front Quick Disconnect/Removal)

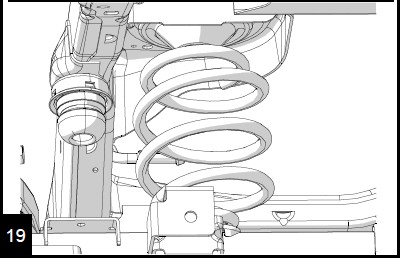

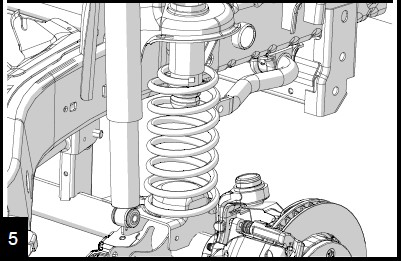

Lower the jack until the spring is free. Remove the coil spring. Be sure to watch the ABS, brake lines and breathers that they are not over stretched..

FRONT INSTALLATION

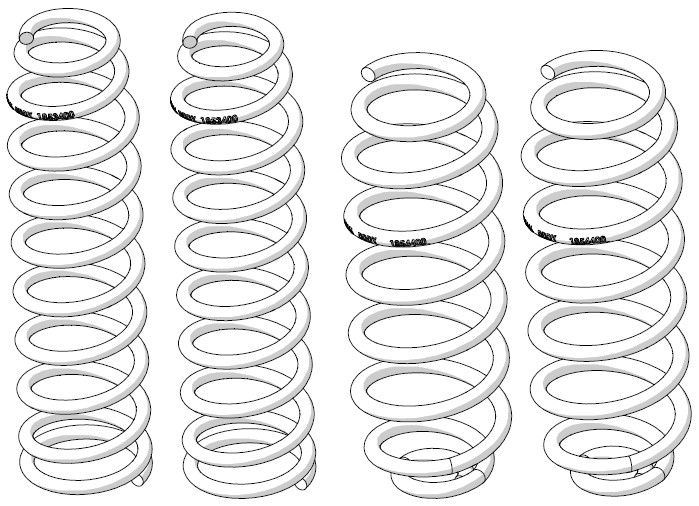

Install both coil springs, drivers side first followed by the passenger side. Rotate the spring until they are fully seated.

Raise the jack high enough to install the shocks. Torque to 56 ft-lbs (76 Nm). (See 999207 Shocks/Front/Installation)

Reinstall the sway bar links or install new links if supplied. Torque top and bottom to 75 ft-lbs. (See 999027 JK Quick Disconnect Links/Installation)

Reinstall the front track bar once the vehicle is sitting on the ground. Torque to 125 ft-lbs. (See 999208 Front Track Bar/ Installation)

Reinstall wheels and tires. Torque lug nuts to 95-115 ft-lbs. Once the vehicle is on the ground, torque upper control arm bolts to 75 ft-lbs and all lowers to 125 ft-lbs.

REAR REMOVAL

12. Refer to the factory service manual for lift locations. Raise and support the vehicle. Remove the tires and wheels and support the axle with a jack or jack stands.

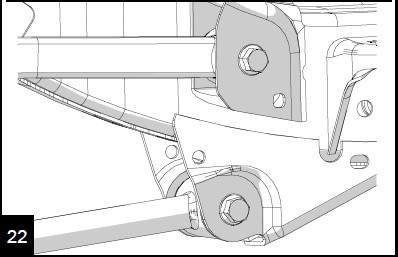

13. Remove the rear track bar at the axle with a 21mm. The nut is a flag nut. (See 999043 Rear Track Bar/Removal)

With a 21mm loosen all rear control arm bolts. DO NOT REMOVE ARMS OR BOLTS.

Remove the shock at the axle with an 18mm. (See 999207 Shocks/Rear/Removal)

Remove the clips that secure the ABS wiring harness to the upper control arm mount.

Remove the parking brake cable bracket from the underside of the body with a 10mm deep socket and discard.

Remove the brake line mount from the frame with a 10mm.

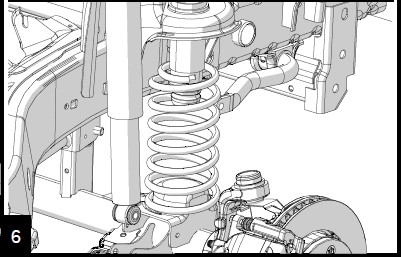

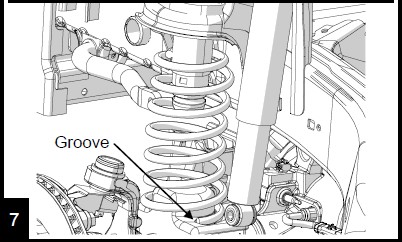

Carefully lower the axle enough to remove the spring. Be sure to watch the ABS, brake lines and breather tubes for overextension. Remove the old spring.

REAR INSTALLATION

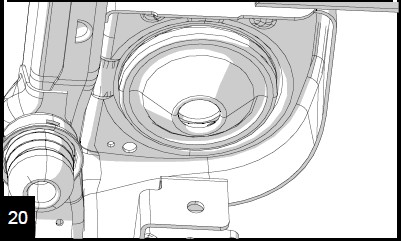

Install the new springs. Make sure to reuse the factory spring isolator.

Raise the axle high enough to reinstall the lower shock bolts. Torque to 56 ft-lbs. (See 999207 Shocks/Rear/Installation) Using a drop bracket if necessary, reinstall the brake line mount to frame. Torque to 16 ft-lbs.

Reinstall wheels and tires, torque to 95-115 ft-lbs. Lower to the ground. Torque all upper control arm bolts to 75 ft-lbs and all lower control arms to 125 ft-lbs.

23. Reinstall the rear track bar at the axle. Have someone push on the body to help align the bolt holes. Torque to 125 ft-lbs. (See 999043 Rear Track Bar/Installation) Recheck every bolt for torque . Re-torque all bolts after 100 miles.

24. To straighten the steering wheel, loosen the adjuster sleeve on the drag link with a 15mm. Make a mark across the sleeve and threads to indicate the original position. Looking from the drivers side, rotate the adjuster sleeve counter clockwise 3/4 of a turn. This should be pretty close. Every vehicle is different, test drive yours and adjust as needed. Torque the pinch clamp bolts to 45 ft-lbs.

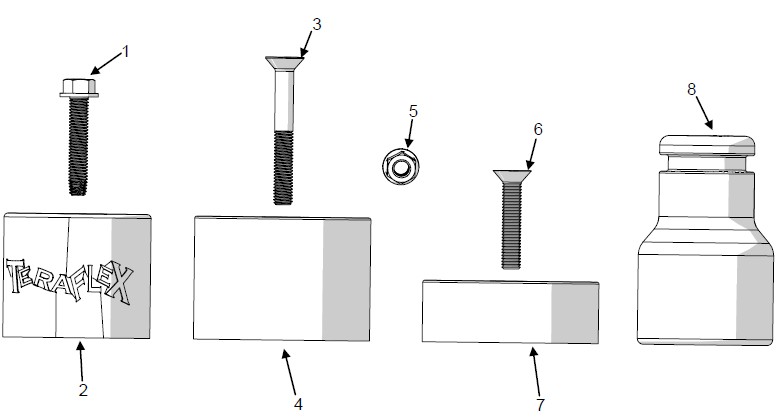

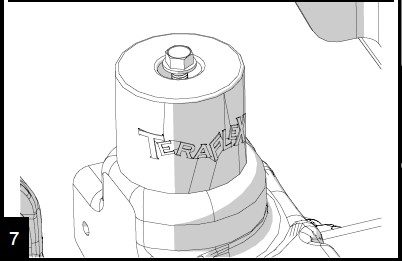

JK Front Bumpstop Extensions

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

INSTALLATION

1. Refer to the factory service manual for lift locations. Raise and support the vehicle. Remove the tires and wheels and support the axle with a jack or jack stands.

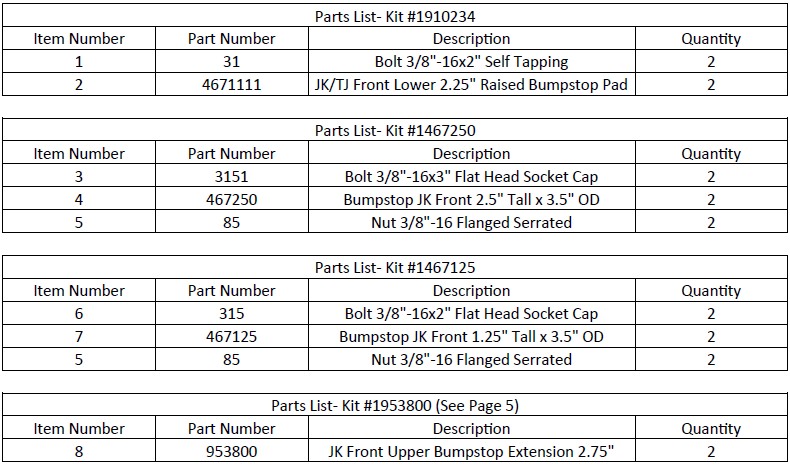

2. Remove the shocks from the axle using a 13mm. Remove the ABS lines at the frame if equipped. Remove the front track bar at the axle with a 21mm. (See Front Track Bar/ Removal 999208)

Remove the shocks at the axle with an 18mm. (See Shocks/ Front Removal 999207)

Disconnect the swaybar links front the axle with an 18mm. (See 999027 Quick Disconnect Links/Removal)

Lower the axle and remove the springs. (See Springs/Front Removal 999206) Upper bumpstop extensions installation see page 5 now.

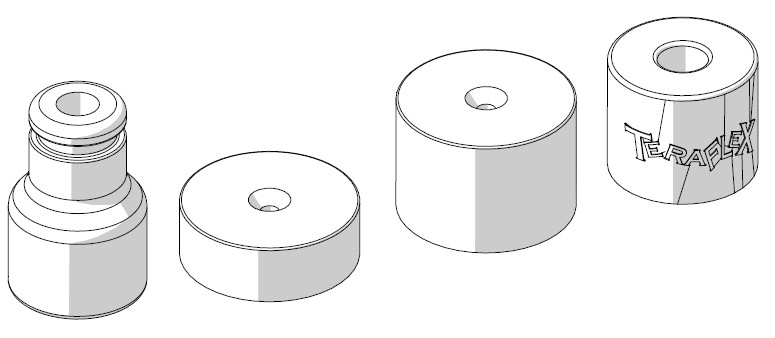

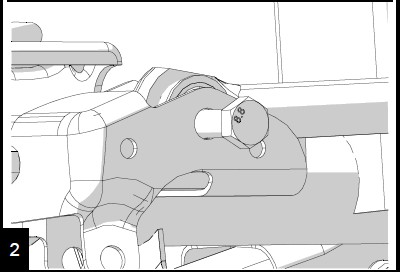

Locate the center of the spring pad and drill a 5/16” hole for standard pad installation. For speedbump pads, drill a 3/8” hole.

Use the standard bumpstop as a guide and thread the self tapping bolt into the hole. After threads are cut, remove the bolt and bumpstop.

Reinstall the springs and spacer together. Install the pad mounting bolt and tighten.

For Speedbump applications, install the bolt through the bumpstop with the nut below the spring pad.

Reinstall the shocks. (See 999207 Shocks/Front/Installation) Torque lower bolt to 56 ft-lbs.

Reconnect the swaybar links to the axle. Torque to 75 ft-lbs.

Reinstall the tires, remove supports and lower to the ground. Reinstall the front trackbar. (See Front Trackbar/Installation)

UPPER INSTALLATION

1. Park the vehicle on a level surface and set the parking brake. Raise the vehicle and support the frame to allow axle droop. Support the axle with a hydraulic jack. Remove the wheels and tires.

2. Perform steps 2-5 of the lower instructions. Then remove the factory bumpstop from the jounce tube by working it back and forth while twisting and pulling to the side.

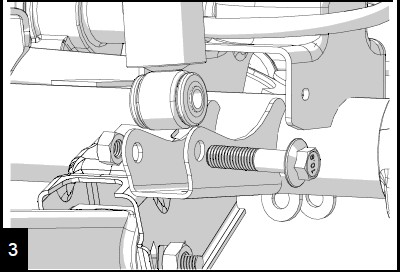

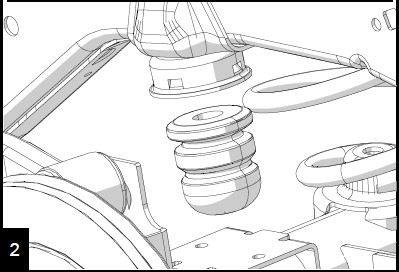

Reinstall the bumpstop by aligning the bumpstop, extension, and jounce tube. Use the hydraulic jack and raise the axle until they are seated together. A grease coating will help.

Reinstall the spring and perform steps 10-12 of the lower instructions.

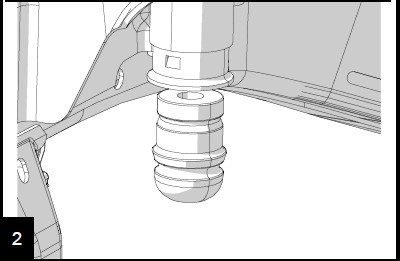

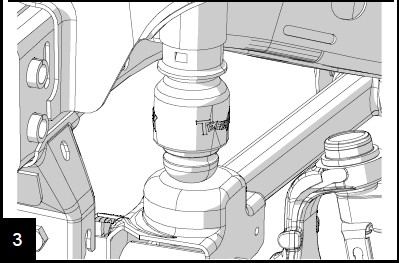

JK Rear Bumpstop Extensions

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

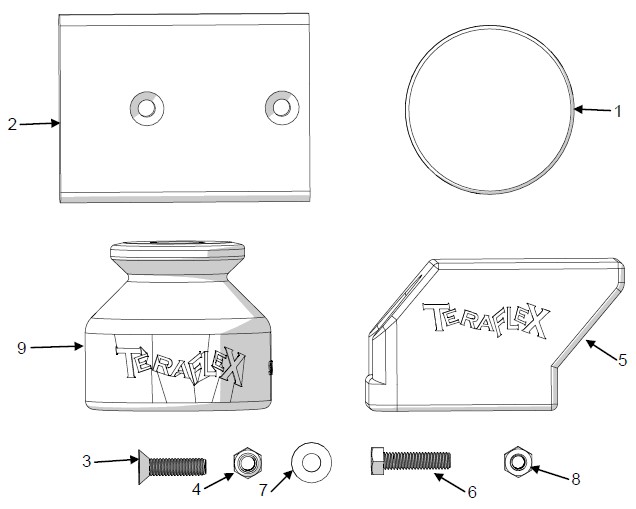

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

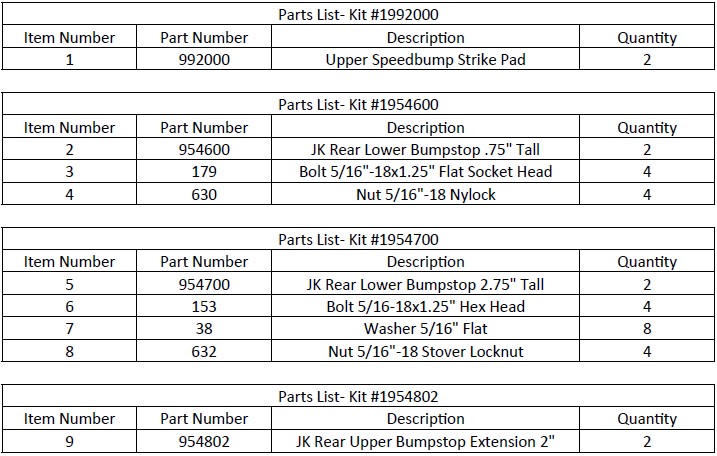

UPPER INSTALLATION

1. Refer to the factory service manual for lift locations. Raise and support the vehicle. Remove the tires and wheels and support the axle with a jack or jack stands.

2. Remove the factory bumpstop from the cup on the frame by working it back and forth while twisting a puling to the side.

Apply grease to the bumpstop and the extension. Or just the strike pad.

Align the bumpstop, extension and frame cup. Place a block between the frame and the axle bump pad. Raise the axle with a jack until the bumpstop and extension seat.

LOWER INSTALLATION

5. Park the vehicle on a level surface and set the parking brake. This installation can be done with the vehicle on the ground. Installation is the same for the Speedbump lower strike pad.

6. Align the extension on the factory pad with the “shelf” towards the front of the vehicle. Install the provided bolts with washers into the two holes. Torque to 25 ft-lbs.

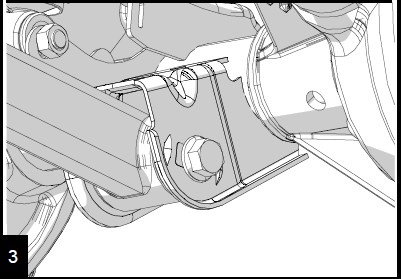

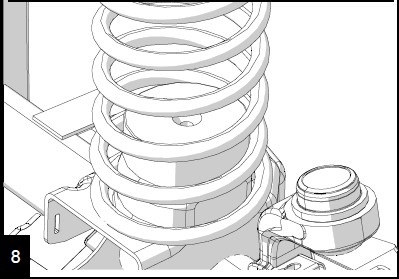

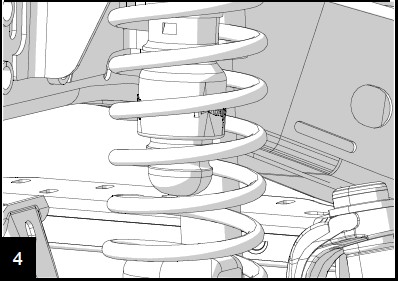

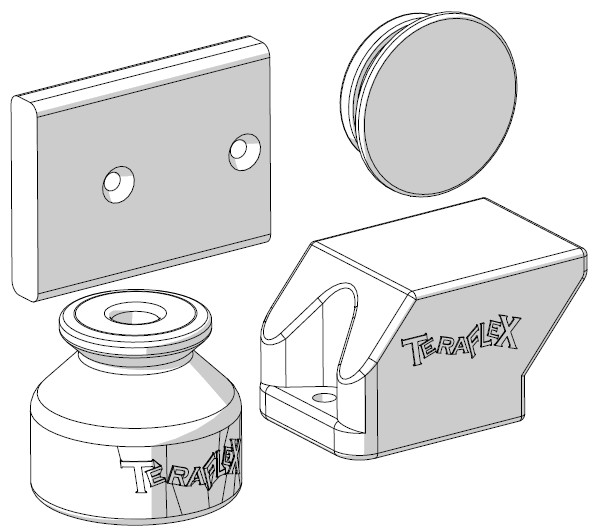

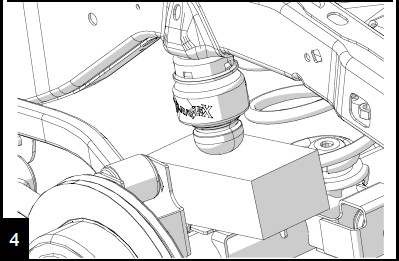

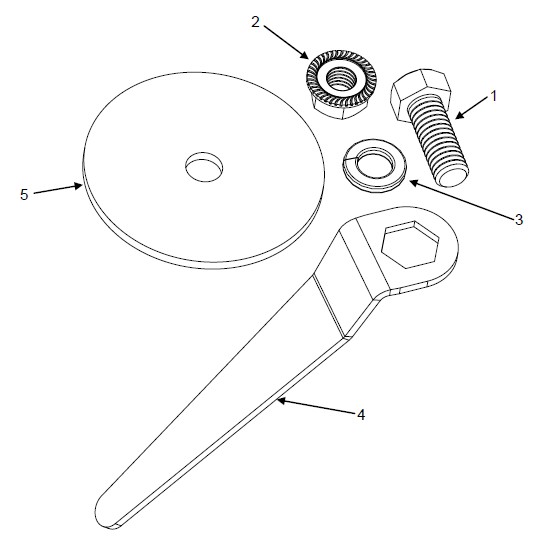

JK Rear Lower Spring Retainer

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

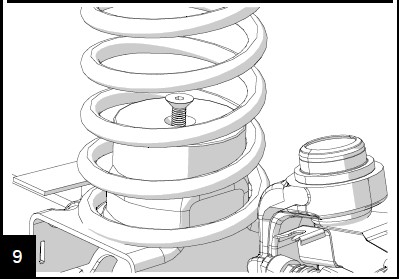

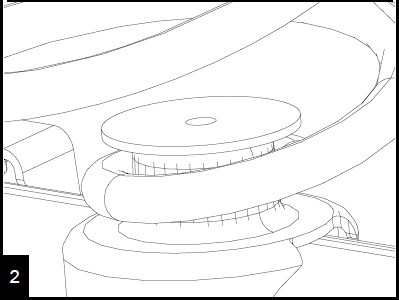

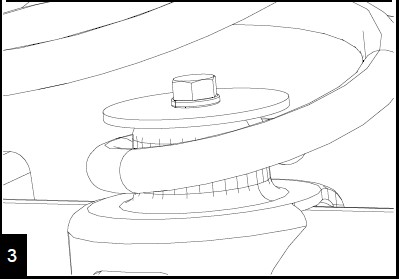

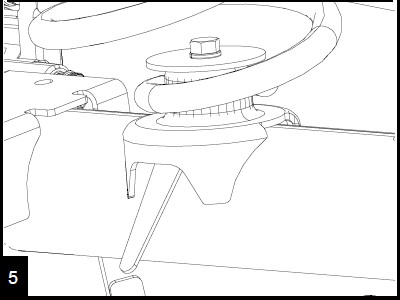

1. Park the vehicle on a level surface and set the parking brake. This installation can be done with the vehicle on the ground.

2. Place the retainer on the lower spring pad.

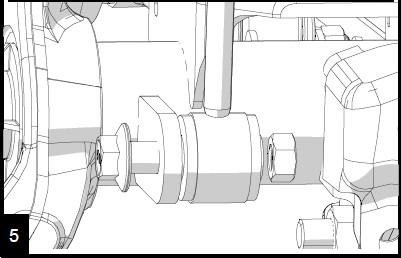

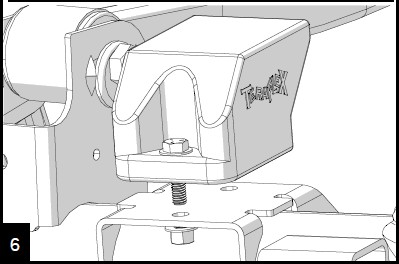

Install the 3/8” bolt and lock washer through the spring retainer and spring pad.

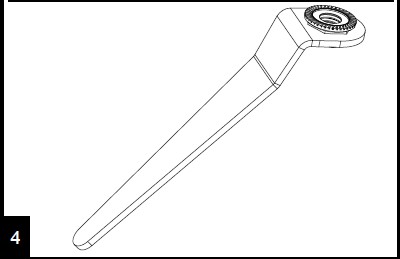

Place a nut into the provided tool. Slide the tool underneath the spring pad from the front of the axle and thread the bolt into the nut.

Torque the bolts to 30 ft-lbs (41 Nm)

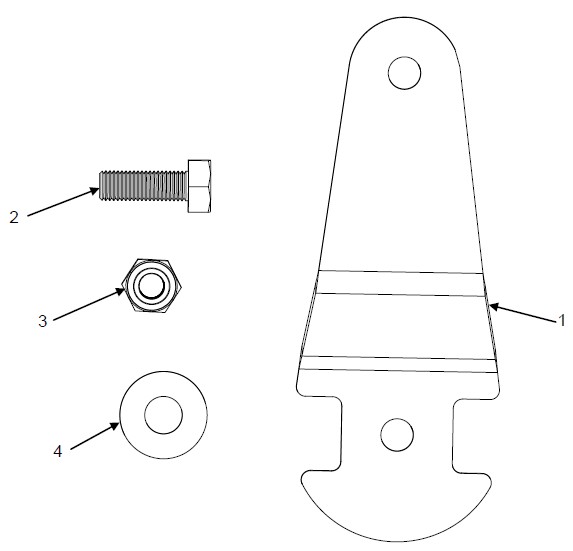

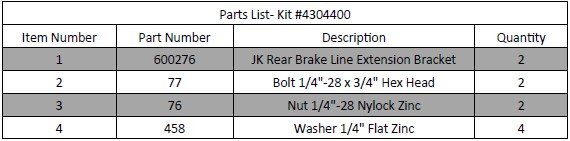

JK Rear Brake Line Extension Brackets

Important Notes:

Prior to beginning this or any installation read these instructions to familiarize yourself with the required steps and evaluate if you are experienced and capable to personally perform these modifications. A factory service manual should be used in conjunction with these installation instructions.

Refer to the parts list to ensure that all necessary components and hardware has been included. If any parts are missing please contact your local TeraFlex dealer for assistance.

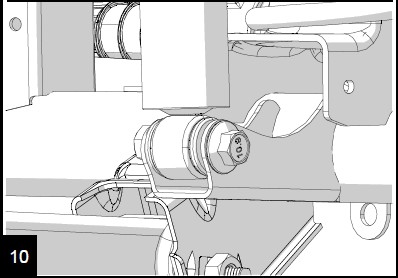

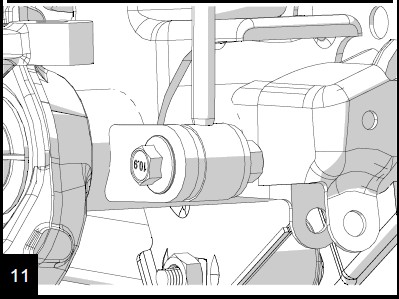

1. Park the vehicle on a level surface and set the parking brake. This installation can be done with the vehicle on the ground.

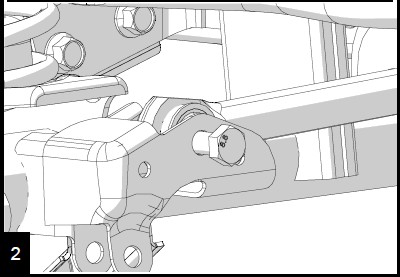

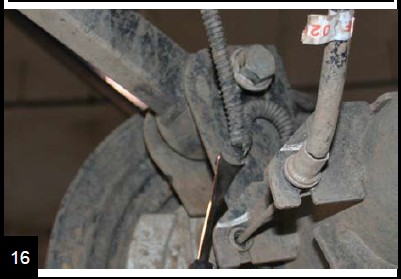

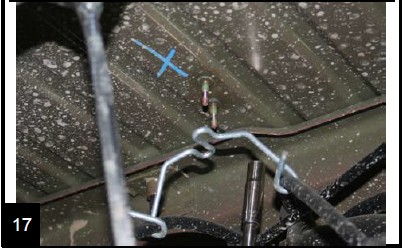

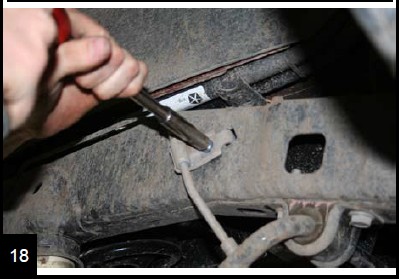

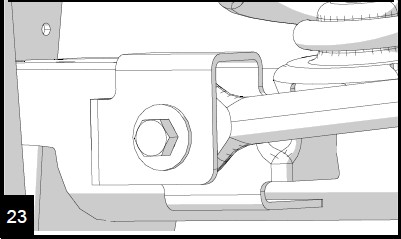

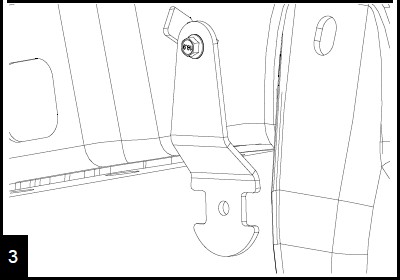

2. Unbolt the rear brake line bracket from the frame with a 10mm.

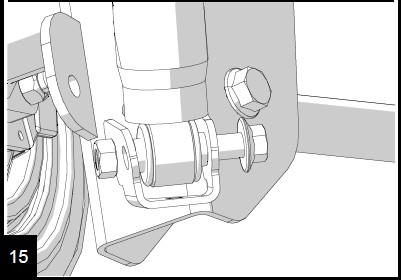

Install the bracket to the frame using the factory bolt. Note orientation with the bend inwards. Torque to 48 inch-lbs (5.4 Nm)

Using a 7/16” wrench and the supplied hardware, bolt the brake line to the bracket with a washer on both sides. Torque bolt to 120 inch-lbs (13 Nm)

Press the hard brake line against the frame to avoid contact with the sway bar links as the suspension cycles.