How to Install a Rugged Ridge Bowless XHD Soft Top w/ Tinted Windows on your 1997-2006 Jeep Wrangler TJ

Shop Parts in this Guide

Contents:

1. XHD Bowless Top

2. Rear Roll Bar Cross Bar

3. Left Side Window

4. Right Side Window

Caution -

This product is designed to enhance the appearance of the vehicle and to shield the occupants from ordinary weather conditions, DO NOT rely on product to contain occupants within the vehicle, or to protect against injury or death in the event of an accident. This top will not protect the occupants from falling objects. Never operate vehicle in excess of manufacture’s specification. SEAT BELTS ARE TO BE WORN AT ALL TIMES.

Note -

An aftermarket (no drill) windshield header will need to be purchased before top can be installed (Rugged Ridge p/n: 13308.04).

Before installing XHD Bowless top, confirm contents and read installation instructions. Failure to do so may result in a poor fitting top and could place occupants in a potentially dangerous situation. The bowless top is designed to use factory plastic door surrounds. The XHD Bowless top (p/n:) must have factory door surrounds and cannot be installed if these parts are missing. After installation, re-read instructions to confirm that the XHD Bowless top has been installed properly before driving.

PLEASE NOTE:

XHD Bowless top should be installed at a temperature above 72F. Below this temperature, the fabric may contract an inch or more, making it very hard to fit to the vehicle.

(Step 1) - With top on the ground, make sure surround foam supports are slid into retaining pockets.

(Step 2) - Install new header to windshield frame. Follow manufacturer's installation instructions for header. Rugged Ridge part number (13308.04).

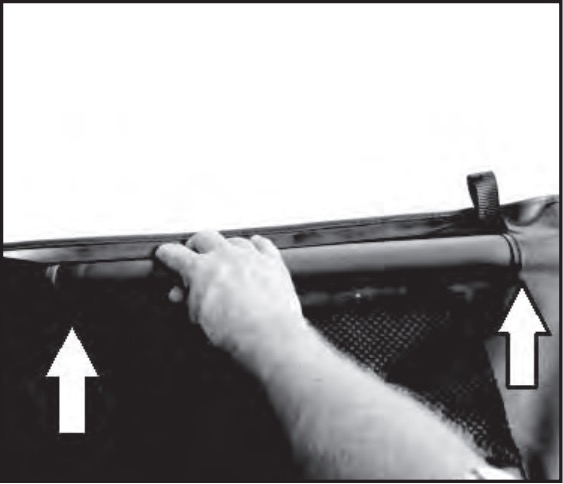

(Step 3) - With the help of a second person, place XHD bowless top (without side windows installed) over roll bar. Make sure cross bar is resting on rear roll bar.

Step 1

Step 2

Step 3

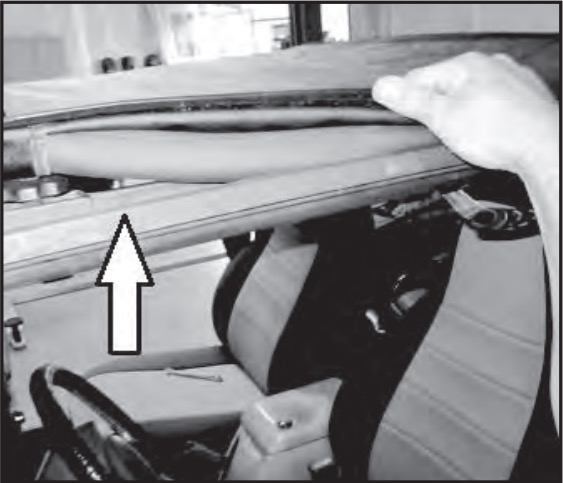

(Step 4) - Slide top forward and position foam supports on top of plastic door surround.

(Step 5) - Pull and lock plastic side retainers into door surround. Front side rain flaps should be pulled out over surrounds.

(Step 6) - Pull top forward and lock front plastic retainer into windshield header. Make sure retainer is held in the full length of header.

Step 4

Step 5

Step 6

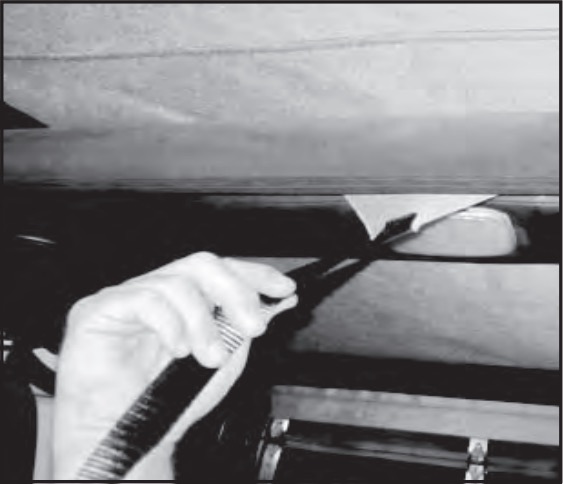

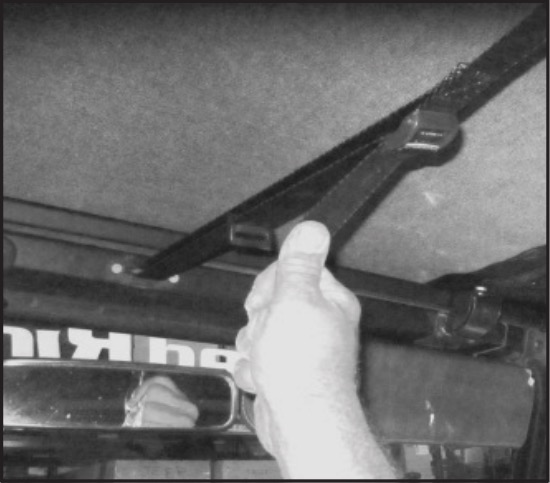

(Step 7) - Slide center strap between roll bar and sound bar. Pull through windshield footman loop.

(Step 8) - Slide strap through buckle and pull tight. Slide second plastic strap loop forward and insert extra strap through loop.

(Step 9) - Pull rear of top into place over roll bar. Rear cross bar should rest at the start of the roll bar turn down. Top should be centered to cross bar and the roll bar.

Step 7

Step 8

Step 9

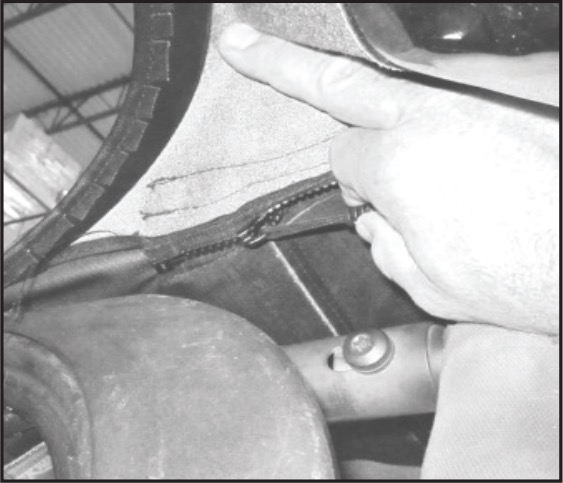

(Step 10) - Attach side window zipper to bowless top. Pull zipper 1/3 back. DO NOT pull all the way back at this time. Repeat for other side.

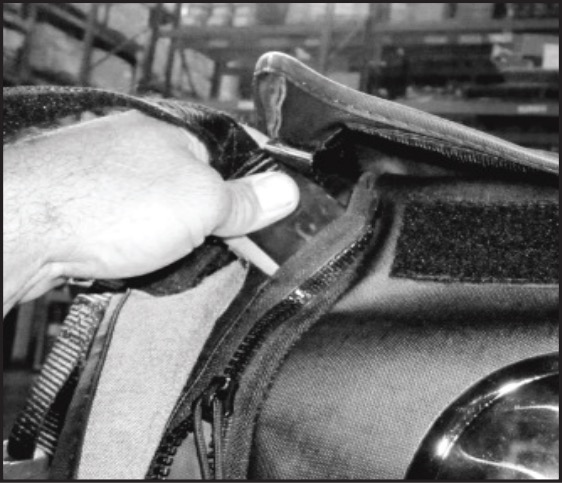

(Step 11) - Attach rear side window zipper to bowless top rear window. Pull zipper down about 3 inches. DO NOT pull all the way down at this time. Repeat for other side.

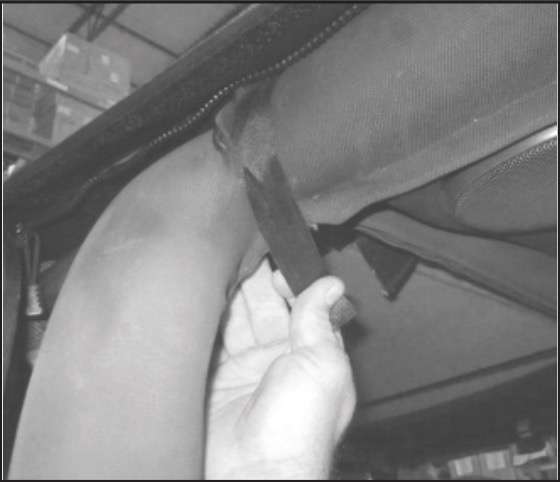

(Step 12) - Fish rear buckle strap behind side window and rear window zipper. Strap should run parallel to roll bar. Repeat for other side.

Step 10

Step 11

Step 12

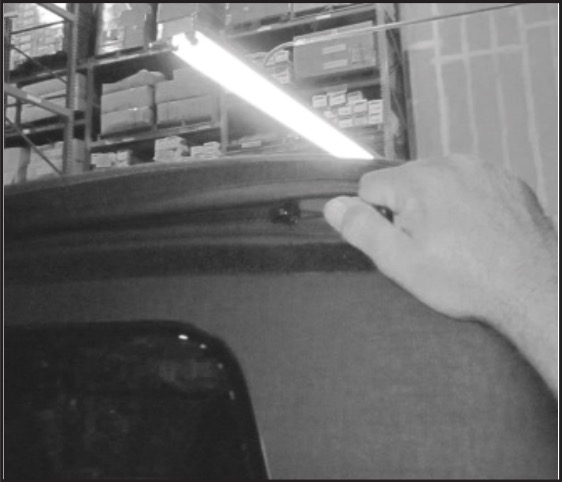

(Step 13) - Pull buckle strap down to body tub. Hook strap to the INSIDE of the tub and pull tight. Secure Velcro straps and repeat on other side.

(Step 14) - Secure inner Velcro straps to roll bar. Straps should be looped to front bar as shown. Repeat for other side.

(Step 15) - Slide front side window plastic retainer into factory door surround. Repeat for other side.

Step 13

Step 14

Step 15

(Step 16) - Working from the front of the vehicle pull side window lower plastic retainer down and lock into body. Pull rear corner down and lock into body. Repeat for other side.

(Step 17) - Pull side window to bowless top zipper all the way back. Pull sides of bowless top over side window and secure Velcro. Repeat for other side.

(Step 18) - Slide rear window tailgate bar onto top. Please note that rear tailgate bar is not supplied with the bowless top. The rear bar is to be reused from factory hardware. If rear bar is needed please order Rugged Ridge part number (13550.01).

Step 16

Step 17

Step 18

(Step 19) - Pull rear window down and lock rear tailgate bar into body tub retainer bracket.

(Step 20) - Pull and lock plastic retainer flaps into body tub.

(Step 21) - Pull rear window zippers down and seal with Velcro flaps.

Step 19

Step 20

Step 21

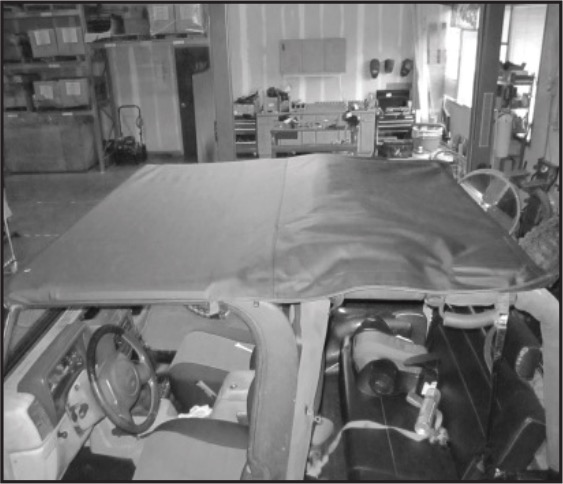

The XHD Bowless Top can be converted to a full length summer island top with the removal of side windows. Side windows are stored above roll bar for protection. No special storage flap or extra buckles are required.

(Step 1) - Remove side windows from vehicle. Removal will be the reversal of steps (10 - 21) from instruction sheets (3 - 4). Remove side Velcro straps from center roll bar.

(Step 2) - Loosen rear buckle strap and remove from vehicle.

(Step 3) - Remove rear tailgate bar from top (bar to be secured back to body tub after removal). Fold top over roll bar with rear window draped over front windshield.

Step 1

Step 2

Step 3

(Step 4) - Fold side windows as shown.

(Step 5) - Place side windows onto front section of bowless top making sure windows are positioned between Velcro strips.

(Step 6) - Fold rear window back over top making sure side windows stay centered. Pull Velcro loose from top of rear window and bowless top. Pull rear window tight and secure to Velcro on either side of bowless top.

Step 4

Step 5

Step 6

(Step 7) - Straps attached to rear window are to be used on vehicles not equipped with a full rear sound bar. Secure straps around roll bar and through plastic buckles. Pull straps tight. DO NOT use straps on vehicles equipped with full roll bar sound bar.

(Step 8) - Fold top over back of vehicle making sure rear window remains secured to Velcro strips. Rear window should be sandwiched between the bowless top and roll bar and sound bar if equipped.

(Step 9) - Position rear cross bar onto vehicle making sure it is properly centered. Pull rear buckle straps back down over roll bar and secure hook to INSIDE of body tub. Pull strap tight and secure Velcro.

(Step 10) - Rear window should be tight. Repeat steps (6 - 9) if glass is not tight.

Step 8

Step 9

Step 10

Washing:

Fabric should be washed often using soap, warm water and a soft bristle brush. Rinse with clear water to remove all traces of soap.

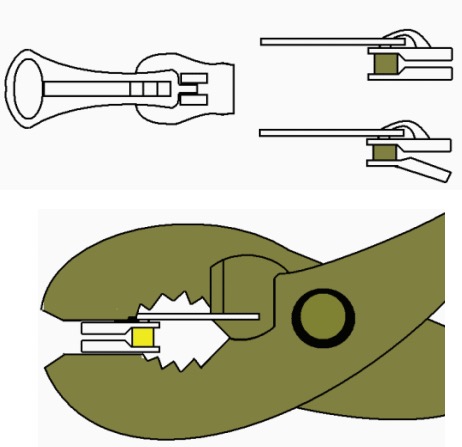

Zippers:

Keep Zippers clean and lubricated with a silicone lubricant. If a zipper opens behind the slider, it can be repaired by using pliers to squeeze sides back parallel. Return Zipper back to normal open position. Squeeze until zipper operates correctly.

Windows:

Keep windows clean to avoid scratches. DO NOT use a brush on windows! Wash with soaked cloth or sponge and mild dish washing detergent. NEVER WIPE WINDOWS WHEN DRY. Be care full when removing snow or ice. Windows will scratch and crack at low temperatures.