How to Install Stainless Works Dual Outlet Axle-Back Exhaust w/ Polished Tips (07-17 Wrangler JK) on your Jeep Wrangler

Shop Parts in this Guide

Thank you for purchasing a Stainless Works exhaust system for your Jeep Wrangler JK/JKU. Our team has done our very best to ensure that this product is the premium in performance, quality, and fitment. We are proud to say that this system will unleash the true character of your vehicle. We encourage you to read through the following steps, and check the included Bill of Materials before beginning. Please follow these steps to ensure that your installation goes as planned.

A. Disconnect the battery before starting work on the exhaust system for your vehicle. Reconnect the battery when the job is completed.

B. Your exhaust system can be installed by a weekend warrior but the use of a lift is recommended for ease of installation. If using a jack, the vehicle must be placed on a level hard surface. Jack stands are required for safety reasons.

C. You will assemble the components together as specified below, but only snug the clamps as you move along from front to back. After aligning all the components in the vehicle, you will tighten all the clamps working from front to back of the vehicle.

D. When installing your catback bumper exit system, make certain that the hangers at the end of the exhaust have at least ¾” of clearance to the bumper. The exhaust will grow over ½” in length and can possibly damage the bumper. If the end of the hangers are too close to the bumper, then you must make sure that you have everything pushed forward onto the slip fit joints more fully.

DISASSEMBLY

1. Disconnect battery.

2. Raise and support vehicle.

3. Beginning near the rear axle, loosen the clamp at the inlet to the rear muffler.

4. Remove the muffler hangers from the rubber insulators.

5. Remove the factory axleback.

If you are only installing the SW axleback (JPJKAB) you can jump ahead to step 12. If you installing a SW catback system continue to step 6.

6. Using an 18mm socket, remove the (4) 12mm bolts from the brace under the transfer case. Set the brace and bolts aside.

7. Loosen the clamp at the inlet to the factory catback and remove the exhaust from the hangers.

8. Reinstall the brace using the same (4) 12mm bolts.

SW CATBACK INSTALLATION

9. Install catback inlet tube to the factory Y-pipe connection point using the original 2½” clamp. Slide the wire hanger into the insulator.

10. Install either the resonator or the muffler delete using (1) of the provided 2½” clamps. We recommend using the resonator for the high clearance dump system (JPJKUCBD). For best results, make sure the muffler is oriented so that the perforations open from the inlet side. With the full catback system you can choose to use the muffler delete for a louder, more aggressive tone. Keep the other option in a safe place, in the event you choose to swap it at a later time.

2 Doors Only: Before installing the tailpipe, 2 door models will require some minor trimming. Measure 21” from the inlet end of the tailpipe, mark and cut at this location. Deburr the end of the tube after cutting.

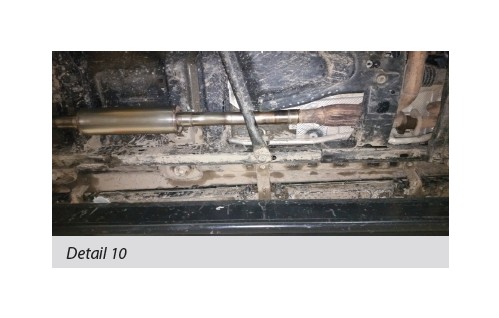

11. Install tailpipe to the resonator using (1) 2½” clamp. Slide tailpipe hanger into the insulator. The over axle tube should be positioned as shown in the picture.

If you are only installing the SW high clearance catback (JPJKUCBD) you can jump ahead to step 14. If you installing a full SW catback system (JPJKUCB) continue to step 12 for axleback installation.

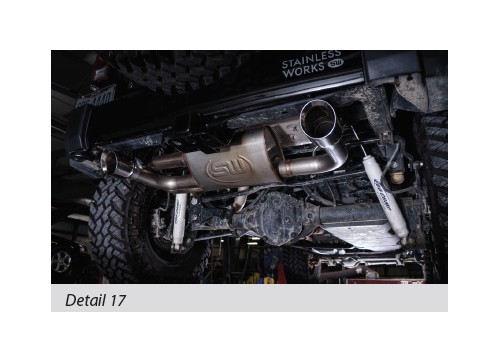

12. Install the SW axleback muffler using (1) 2½” clamp to connect to the tailpipe.

13. Install the muffler into the (2) hanger insulators.

14. Adjust your exhaust system as needed, working from front to back, and tighten.

15. Lower the vehicle.

16. Reconnect battery.

17. After double checking for clearance and making sure all lines, wires, and hoses are secured, drive the car for 10-20 miles and re-check all clamps and clearances. Your system can be tack welded at the joints/clamps to reduce shifting of the system during heating and cooling cycles. Be sure to disconnect the battery before performing any welding.