How to Install SkyJacker 4" Value Flex Lift Kit on your 1987-2006 Wrangler

PRE-INSTALLATION NOTES:

• A professional mechanic is recommended to perform the installation.

• Read the instructions carefully and study the photo illustrations before attempting the installation.

• Secure and properly block the vehicle on a level concrete or asphalt surface.

• Always wear safety glasses.

FRONT:

1. Secure and properly block the tires of vehicle on a level concrete or asphalt surface.

2. Jack up front of vehicle and install jack stands under frame behind the lower link rear brackets. Remove tires and front shocks. Now remove

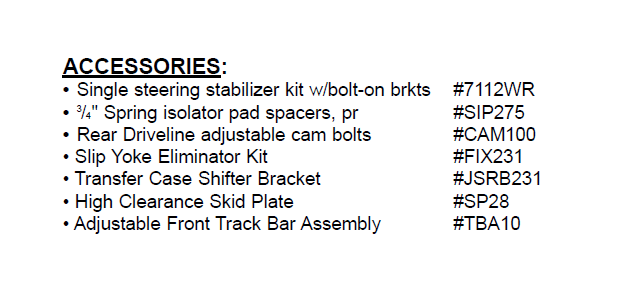

steering damper, also remove track bar from passenger side axle (see photo #1) and driver side frame (it may be necessary to pry loose).

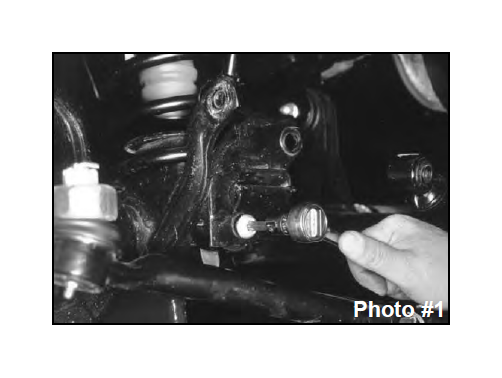

3. Remove drag link assembly from pitman arm and lower it down. (For 4" lifts, remove pitman arm also.) Now remove the sway bar end link's lower bolt at axle housing on

both sides (see photo #2). Lower front axle down until coil springs become loose.

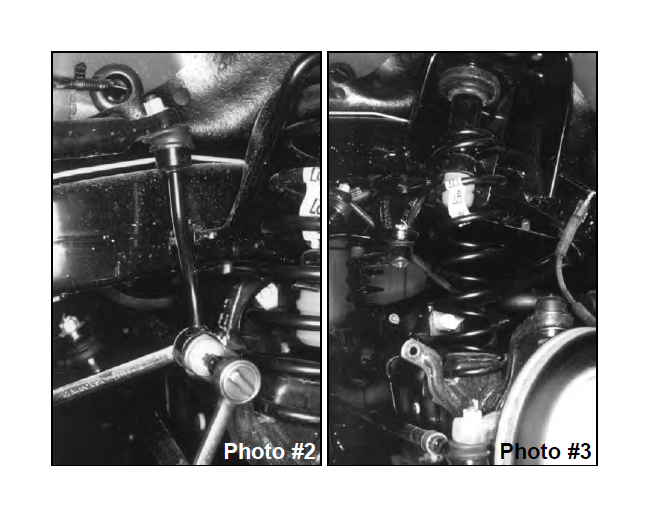

Remove the bottom bolt and clip from left front coil spring (see photo #3). At this time

install new polyurethane tie rod dust covers.These will install on each end of the drag link and tie rod.

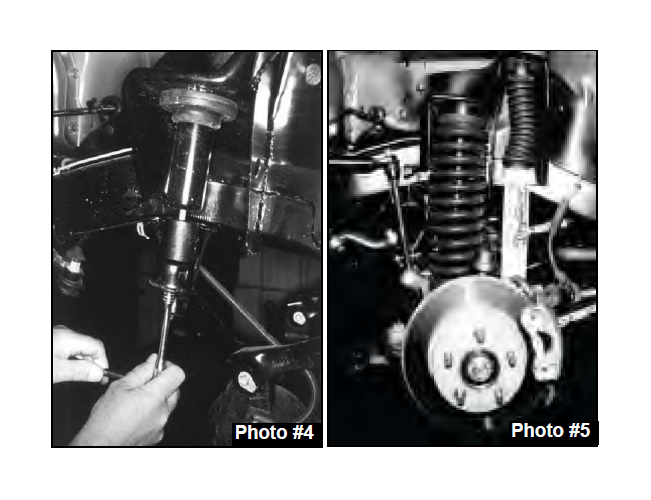

4. Now remove both coil springs. Remove upper bump stop (use channel lock pliers working bump stop back and forth). 21/2" Lifts: remove bolt from inside bump stop cup. Install bump stop spacer and original cup using 10mm x 13/4" long bolts furnished. Reinstall factory bump stop. (See photo #4.) 4" Lifts: Install new red poly-urethane longer bump stops.

5. Install new coil springs. Raise jack up so that enough load is applied to hold coil springs in place. Reinstall spring bolt and clip at bottom of left front coil.

6. Install new shocks. (See photo #5.) On 4" lifts, install new drop pitman arm at this time. Reinstall drag link to pitman arm and tighten (be sure to install cotter pin). Install tires and lower front to the ground.

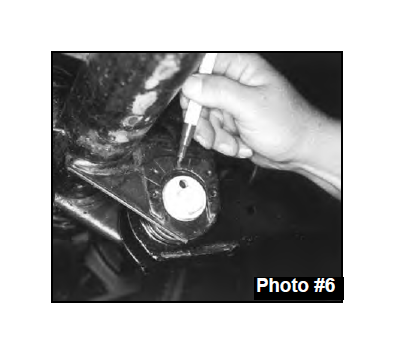

7. At the front lower link adjustment cams, mark (with an ink marker, or scribe a mark) the vertical line on the cam and the reinforcement bracket for reference so you can realign the

marks after installation. (See photo #6.)

8. On Single Flex links assemblies: install drive-in zirc fittings in the end of the links (that will be using poly bushings) by using a 1/4" socket over the fitting, tap with a hammer until fitting is completely tapped in. Install poly bushings and steel sleeves into

eye of lower links: Lower uses bushing #2617, sleeve 2.645" long, Upper rear uses bushing #2887, sleeve 2" long. Grease them prior to installation.

9. Now you are ready to "set" the length of the new Flex Series link assemblies.

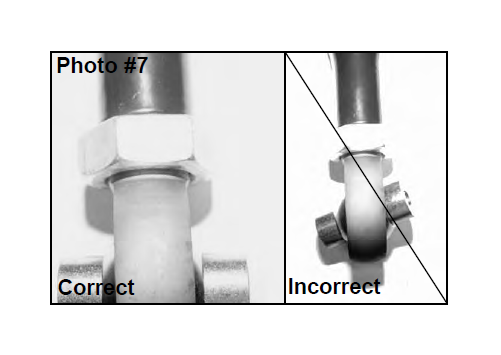

A) It is very important to position the swivel ball socket so that the bushings are exactly centered (see photo #7).

B) Measure the length of the link assembly between the center of each eye on each end. Rotate the rod end as needed, being sure to keep the ends square with each other until link

assembly measures:

Lower Front and Rear should be 16 1/16",

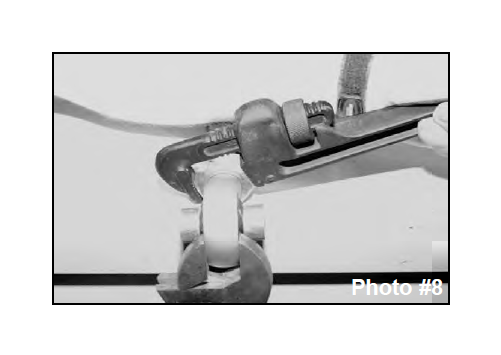

C) On the rod end, rotate jam nut against steel tubing. Hold the rod end in place with a crescent wrench, and using a pipe or crescent wrench on the jam nut, completely tighten.

NOTE: Jam nuts must be tight against steel tubing before installation. D) Recheck center-tocenter measurement to be sure it is correct, and that the ends are square with each other.

IMPORTANT: Under no circumstances should rod end (heim) be adjusted out more than 1/2" (including the jam nut) from the steel tubing of link assembly!

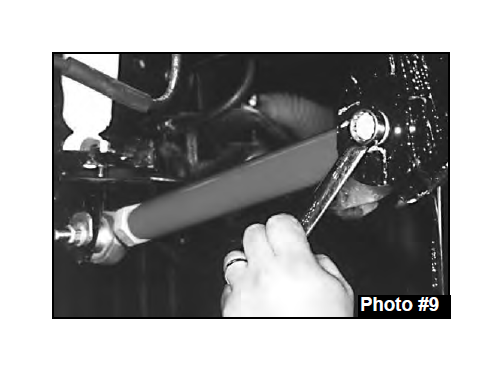

10.Remove and replace the lower links with new

Skyjacker® Flex Series links. Only start these bolts and nuts, do not tighten at this time. (On Single Flex Lower links, the adjustable rod end is installed at the axle.) Once all links are installed, tighten each link being sure to realign marks on the eccentric cams. (See photo #9.)

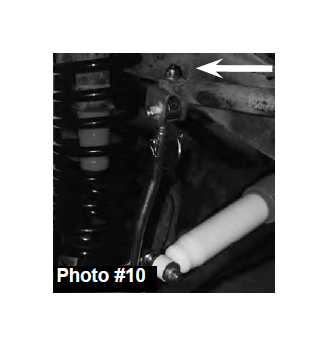

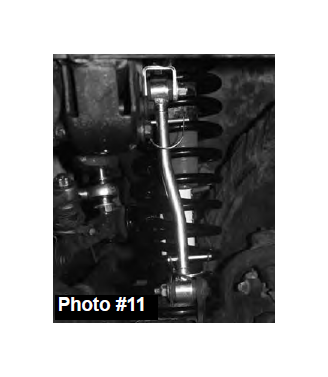

11. Install new sway bar end-links. The new end link mounting bracket should be mounted to the bottom of the sway bar with the bolt pointing up through the sway bar and the nut and washer applied on top (see picture 10). Apply lithium grease to the metal sleeves & insert them into the end link eyes. The top 1/2" x 2 1/2" bolt connecting the bracket to the end link must be installed with the nut to the outside of the vehicle to provide adequate clearance to the frame. Install new double disconnect end links on the inboard side of the axle bracket.(see picture #11).

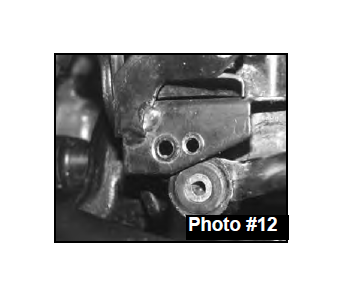

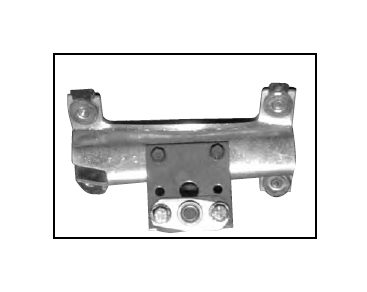

12. 21/2" Lifts: Reattach track bar in original axle mount (it may be necessary to rotate steering wheel left or right to align bolt hole). 4" Lifts: Locate the front track bar mounting bracket on the axle, measure straight across to the right (inward) 3/4" and put a mark. Center punch and drill a 7/16" hole through both front and back plates, keeping the drill as straight and square to the bracket as possible (see picture #12). Reattach track bar (it may be necessary to rotate steering wheel left or right to align bolt hole).

13.Place a jack under transfer case crossmember and remove the 4 screws that mount the transfer case pivot assembly from the body of vehicle (it will be necessary to roll floor mat back to gain access to bolts).

14.Remove the 3 bolts on each side of transfer case skid plate and lower down enough to install new square tube spacers between skid plate and frame. 1997-02 models use the flat socket head tapered bolts supplied. (2003 models will use the

12mm bolts and washers supplied). Also apply a few drops of supplied thread lock compound on bolt threads prior to installing. Tighten bolts to 75-80 ft.lbs. (Picture #13)

* On 2003 models, also remove the 2 engine skid plate bolts. Install the small square tube spacers at the mounting points on the frame rails, along with the 12mm bolts supplied. 2.5” kits will use the 1” square tube spacers. 4” kits will use the 1.5” spacer.

15.Install the new transfer case linkage pivot drop bracket to stock pivot bracket using stock screws. Using the two 1/4 x 1" bolts with a flat washer and self-locking nut, bolt the ball swivel bracket (arrow in photo #14) to new drop bracket (bracket has 2 sets of holes: bottom holes for 4" lift as shown, or next to bottom for 21/2" lift). Placing pivot bracket back in location, start end of rod through ball swivel. Now bolt bracket back into location with original hardware (photo #15).

REAR:

16.Place a floor jack under rear axle and raise vehicle. Place jack stands under the frame ahead of lower link bracket to support vehicle and remove the rear tires and shock absorbers.

17.Remove rear track bar and sway bar end link bolts at axle housing. Lower rear axle down to remove coil springs.

18.After removing both coil springs, remove the bump stops (it may help to use channel lock pliers working bump stop back and forth). Remove 10mm bolt from inside bump stop cup. Install bump stop spacer and original cup using furnished 10mm bolts

Reinstall factory bump stop. Optional poly bump stops (like the front) are available on 4" lifts, part #BP50.

19.Place new rear track bar relocation bracket in position and place track bar in new bracket (do not start its bolt). Start the new 12mm x70mm (23/4" long) bolt through the original track bar location using the supplied spacer sleeve (#54314) with a self-locking nut. Tighten bolt.

Now drill a 1/2" hole through the hole in end of new bracket., Remove the 12mm x 70mm bolt, installed before drilling, and install a 1/2 x 11/2" bolt, with a washer on each side, through the new drilled hole, and then tighten with self-locking nut. (See photo #16).

Reinstall the new 12mm x70mm (23/4" long) bolt through the original track bar location using the supplied spacer sleeve (#54314, see arrow in photo #17) with a self-locking nut and tighten. Still do not bolt up the track bar yet (must wait till on the ground).

20.Install new coil springs. Raise jack up so that enough load is applied to hold coil springs in place.

21.Remove and replace the lower links with new Skyjacker® Flex Series links. Only start these bolts and nuts, do not tighten at this time. The Single Flex Lower links are

installed at the adjustable rod end at the axle. Once all links are installed, tighten each one. (See photo #18.)

22.Assemble the new rear extended sway bar end links by applying grease to the metal sleeves and inserting them into each eye. Install using original bolts. (refer to photo #18)

23.Install new shocks, install tires and lower rear to the ground. Now bolt track bar to new relocation bracket using original hardware (refer to photo #16-17). Also be sure

original upper track bar bolt is tight.

WARNING: On these Wrangler TJ Jeep models, only the shock absorbers limit the extended position of the front and rear suspension! The use of shocks other than those

supplied in this system, may cause coil disengagement, adverse steering angles, brakehose failure, driveline component failure, and/or other related component failure! The use of other shocks will void your Skyjacker® warranty!

FINAL NOTES:

• Check clearance between inner side wall of tires and links. It may be necessary to adjust steering stops (by adding 2-3 washers on bolt) to eliminate interference. (See photo #19)

• Check the transfer case shifter to see if it will move to 4L. If not, the linkage will need adjusting as follows. Place the shifter in 4L, loosen adjustment bolt ("A" arrow in photo #20), and push the linkage ("B" arrow in photo #20) forward until it stops. Now retighten adjustment bolt. Check to be sure 4WD works properly.

• On 5 speed models, engage the clutch and check the transmission shifter to see if it will go into 2nd gear. If not, the shifter housing on the floor will need trimming. Remove center console, pull back carpet, remove the screws holding shifter boot to floor and trim or grind floor board at arrow in (photo #21) until sufficient clearance is obtained. Shift through each gear to check clearance at this time. Now reinstall boot, carpet and console.

• Front end realignment is necessary so after the lift is installed have a qualified alignment center realign front end to factory specifications.

• Rotate driveshafts and check for interference at differential yoke and cardan joint. If necessary, lightly dress casting(s) and/or U-joint tabs in order to eliminate binding.

• Ensure there is adequate clearance between exhaust and brakelines, fuel lines, fuel tank, floor board, and wiring harnesses. Check steering gear for interference and proper working order. Inspect brakelines for damage and adequate clearance. Test brake system before driving.

• With the vehicle on the floor, cycle steering lock to lock and inspect steering, suspension, driveline and brakeline systems for proper operation, tightness and adequate clearance.

• Have headlights readjusted to proper settings

• If you purchased the Skyjacker® TJ rear driveline cam-bolt kit install as follows.

Remove the bolt in rear upper link (the end toward rear bumper) and raise link up out of mounts.

Note the hole is notched so that it can be a slotted hole. Knock out the notches on the

front and rear half of the holes on each side of the link mounts (see arrows in photo #22).

Repeat on other side.

Lower links back into mounts. Install new eccentric cam-bolts, eccentric washers and

nuts on each link and tighten. These bolts can be rotated to adjust the axle pinion angle to eliminate any driveline vibration. Driveline vibrations can be caused from the

removal or addition of the hardtop which changes the rear vehicle weight, and the rear

height which affects the rear drive shaft pinion angle. This Cam-bolt will eliminate such vibrations by rotating the axle correcting the angle.(see photo #23)

Steering box skid plate installation instructions

1. Remove the driver side lower bumper bolt (bolt #1) also remove lower steering box mounting bolt (bolt #2) from frame as shown in figure #1.

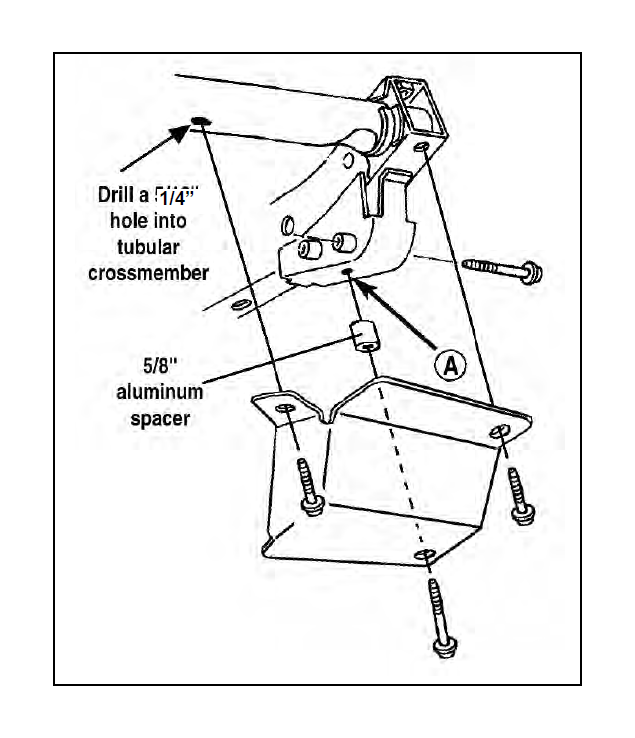

2. Holding the skid plate in place, placing the three holes in the skid plate over the existing holes in frame.

3. With the skid plate in place, replace the bumper bolt (bolt #1) and steering box bolt (bolt #2).

4. Use the existing hole in the frame (A) to line up the rear skid plate bolt.Put the nut inside the frame.

5. Put the 5/8" aluminum spacer in place, shim accordingly with supplied washers and install the 3/8" x 2" bolt (bolt #3).

6. With the skid plate in place, locate the remaining hole in the ear of the skid plate. With the hole as a guide, use a center punch to mark the location you will be drilling.

7. Drill a 1/4” hole in the frame at the location you just marked.

8. Screw the 5/16" self-tapping bolt (bolt #4)into the hole you just made and tighten.

Items Included In This Kit:

• 2 1/2" washers

• 1 3/8" fine thread nut

• 1 3/8" washer

• 1 3/8" x 2" fine thread bolt

• 1 5/16" self-tapping bolt

• 1 5/8” aluminum spacer

• 1 steering box skid plate

NOTE: This Steering Box Skid Plate is compatible with oversized AGR aftermarket steering boxes.