How to Install Rugged Ridge Spartacus Heavy Duty 12,500 lbs Winch w/ Synthetic Rope on your Wrangler

Installation Time

30 minutes

Tools Required

- 9/16” socket

- 1/2” socket

- 5/8” socket

- Socket wrench

- Torque wrench - optional

- Safety glasses

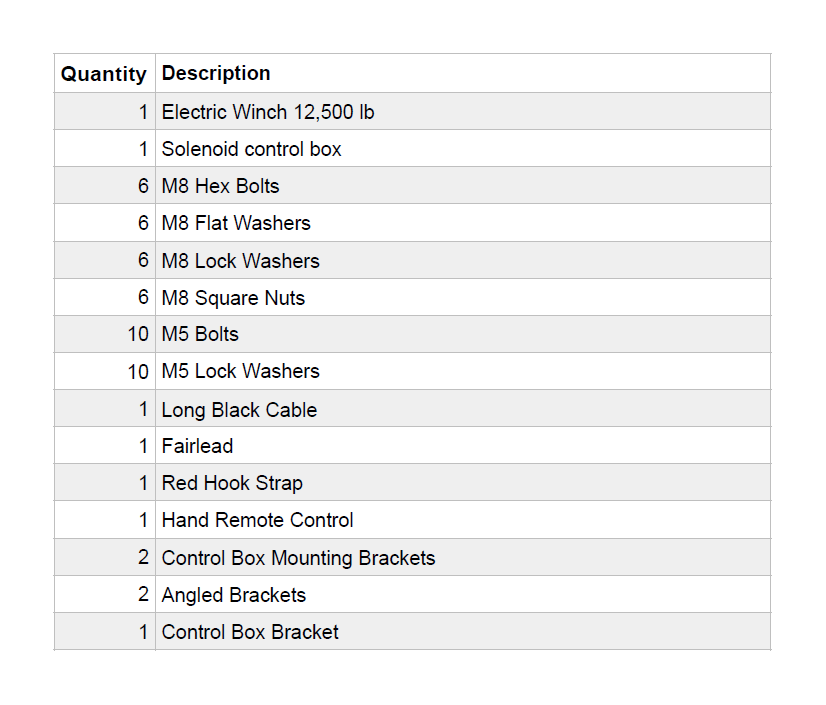

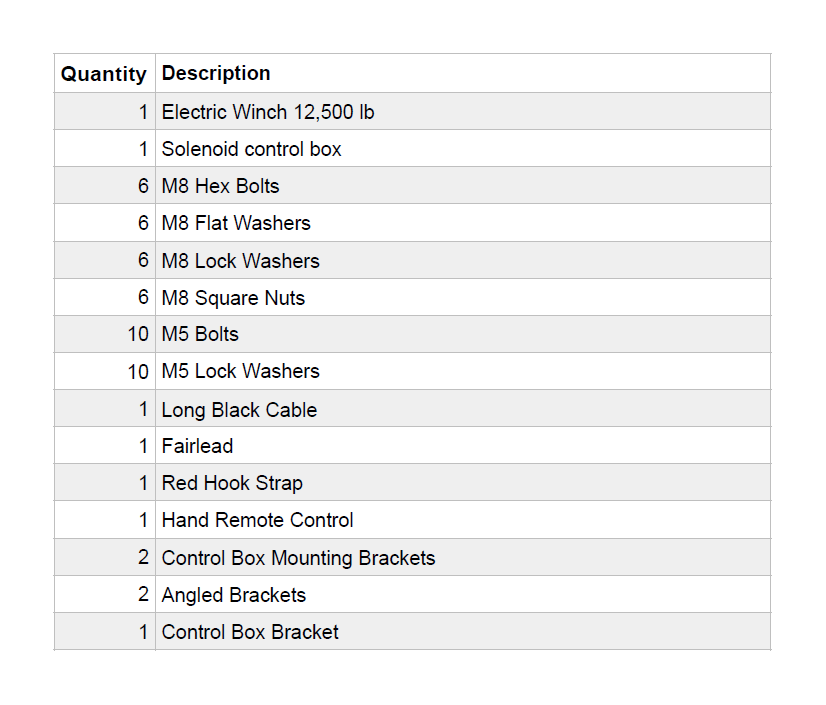

Parts list included

Parts list included

1. Park vehicle, turn off engine and engage the parking brake

2. Be sure to wear safety glasses for the entire install as loose debris and dirt on

the underside of the vehicle can dislodge and fall into your eyes

3. Lay out all parts from shipping box and organize what you need.

1. Park vehicle, turn off engine and engage the parking brake

2. Be sure to wear safety glasses for the entire install as loose debris and dirt on

the underside of the vehicle can dislodge and fall into your eyes

3. Lay out all parts from shipping box and organize what you need.

4. Begin assembly by connecting the wires from the control box to the winch

motor. Each wire has a corresponding color-coded connection on the motor.

4. Begin assembly by connecting the wires from the control box to the winch

motor. Each wire has a corresponding color-coded connection on the motor.

**Before connecting any wires, be sure to slide the colored wire cover back

behind the wire terminal connection**

These covers easily slide back to reveal the terminal connection.

**Before connecting any wires, be sure to slide the colored wire cover back

behind the wire terminal connection**

These covers easily slide back to reveal the terminal connection.

5. Connect all color-coded wires to the matching color-coded bases and leave

them a little loose. At this point, you need to decide where to mount your control

box BEFORE tightening the wires to the motor. The control box location will

determine in which position to direct the wires before tightening.

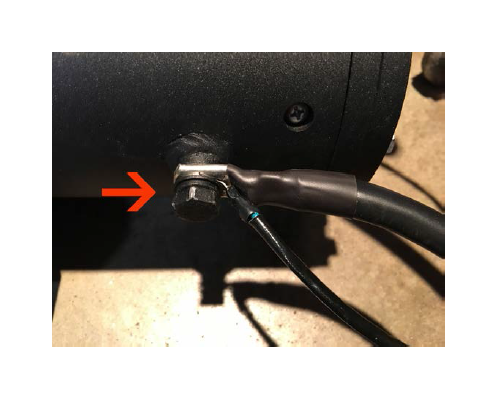

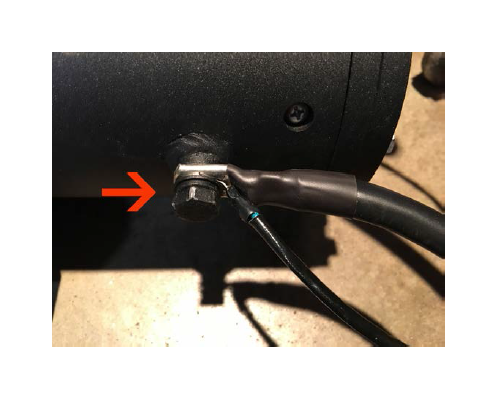

6. Connect the small ground wire and long black cable to the bottom of the motor.

Be sure NOT to connect the small ground wire to the upper black terminal.

This is what it should look like.

5. Connect all color-coded wires to the matching color-coded bases and leave

them a little loose. At this point, you need to decide where to mount your control

box BEFORE tightening the wires to the motor. The control box location will

determine in which position to direct the wires before tightening.

6. Connect the small ground wire and long black cable to the bottom of the motor.

Be sure NOT to connect the small ground wire to the upper black terminal.

This is what it should look like.

7. Time to mount the control box to the winch. I chose to mount mine on the

motor using the control box bracket.

This is where you will mount the bracket before mounting the control box. You will use the existing bolt on the left and add a M5 bolt with M5 lock washer on the right side.

7. Time to mount the control box to the winch. I chose to mount mine on the

motor using the control box bracket.

This is where you will mount the bracket before mounting the control box. You will use the existing bolt on the left and add a M5 bolt with M5 lock washer on the right side.

8. After you mount the control box bracket, loosen the M5 bolts on the right side

of the control box (2 total) and back them out about half way. Then slide the bolts

into the existing holes on the control box bracket and tighten them down.

This is what it should look like when you’re finished.

8. After you mount the control box bracket, loosen the M5 bolts on the right side

of the control box (2 total) and back them out about half way. Then slide the bolts

into the existing holes on the control box bracket and tighten them down.

This is what it should look like when you’re finished.

9. Now, go back and make sure to tighten all color coded wire going from the

control box to the motor and slide the color-coded wire covers over the terminals.

This part requires a little patience, but it’s a critical step in preventing damage to your winch. Don’t skip this step!

9. Now, go back and make sure to tighten all color coded wire going from the

control box to the motor and slide the color-coded wire covers over the terminals.

This part requires a little patience, but it’s a critical step in preventing damage to your winch. Don’t skip this step!

TIME TO MOUNT THE WINCH!

10. First, lay the winch on it’s side and grab the 4 M8 square nuts and slide them

into the slots on the bottom four corners of the winch.

TIME TO MOUNT THE WINCH!

10. First, lay the winch on it’s side and grab the 4 M8 square nuts and slide them

into the slots on the bottom four corners of the winch.

The trick here is to slide them all the way to the back of the winch and make sure

they’re seated properly. This way, they will be in perfect alignment when it’s time

to install the M8 bolts.

11. Gently, set the winch on the mounting plate, mine is my winch bumper, and

align the four holes on the bottom of the winch with the four holes in your

mounting plate.

12. Go to the underside of your Jeep and insert the M8 bolts, M8 washers and

M8 lock washers.

The trick here is to slide them all the way to the back of the winch and make sure

they’re seated properly. This way, they will be in perfect alignment when it’s time

to install the M8 bolts.

11. Gently, set the winch on the mounting plate, mine is my winch bumper, and

align the four holes on the bottom of the winch with the four holes in your

mounting plate.

12. Go to the underside of your Jeep and insert the M8 bolts, M8 washers and

M8 lock washers.

This is what it should look like. Be sure to hand tighten each bolt until all bolts are

seated and threaded properly and then tighten them down. Be sure not to over

tighten any bolts.

13. Time for the main wiring to the Jeep battery. For this step you can run your

wires in any route you choose. I chose to go through the grill and up by the

radiator to the battery.

This is what it should look like. Be sure to hand tighten each bolt until all bolts are

seated and threaded properly and then tighten them down. Be sure not to over

tighten any bolts.

13. Time for the main wiring to the Jeep battery. For this step you can run your

wires in any route you choose. I chose to go through the grill and up by the

radiator to the battery.

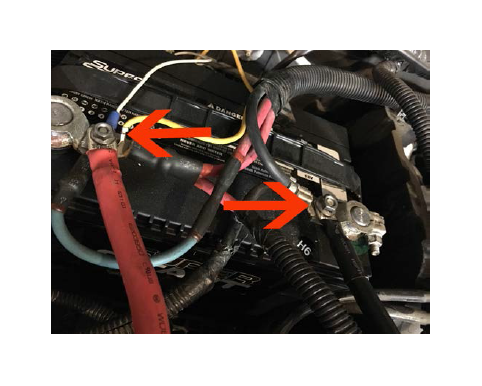

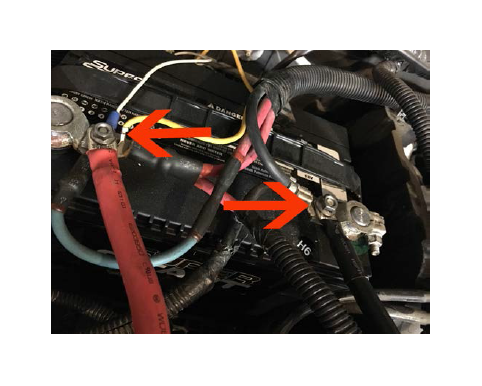

14. After you run your wires to the battery, make sure they’re not going to snag

anything in the engine compartment and connect the wires to the positive and

negative battery terminals.

Be sure to tighten the terminals back to the same torque they used before connecting the winch wires.

14. After you run your wires to the battery, make sure they’re not going to snag

anything in the engine compartment and connect the wires to the positive and

negative battery terminals.

Be sure to tighten the terminals back to the same torque they used before connecting the winch wires.

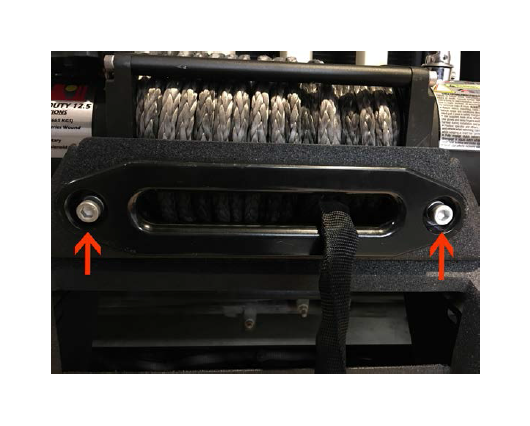

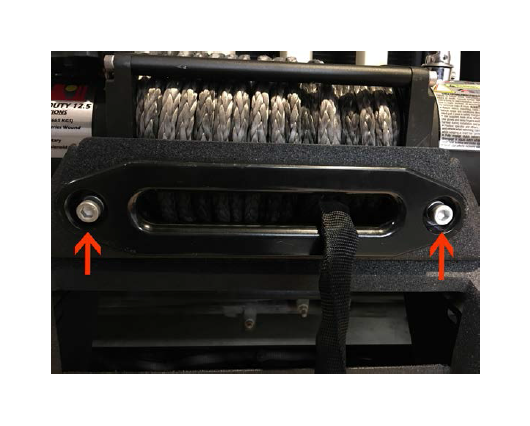

15. Mount the fairlead to the winch plate.

For this step, you will use 2 M8 bolts, lock washers and nuts.

15. Mount the fairlead to the winch plate.

For this step, you will use 2 M8 bolts, lock washers and nuts.

You’re all set! Time to admire your new winch and go test it out!!!

You’re all set! Time to admire your new winch and go test it out!!!