How to Install Rough Country 2.5" X-Series Suspension on your 1997-2006 Wrangler

Tools Required

- Spring Compressor

- Silicone spray

- Drill assortment

- Combination wrenches

- T-55 key socket

- Floor jacks

- Wheel chocks

- 1 1/8" Wrench

- 1 7/8" Wrench

- 1/2" drill motor

- Torque wrench

- 1/2 drive ratchet and sockets

- Allen wrenches

- Large “C" clamps and /or bench vise

- Hea

FRONT INSTALLATION

1. The front-end components are installed first.

2. Place the vehicle on a level surface. Set the parking brake. Center front wheels and chock rear wheels. From inside the engine compartment, remove the upper stud nut, retainer and grommet from both of the front shocks using a 15mm socket.

3. Place jack stands on the frame rail behind the lower control arm mount on the frame and jack up the vehicle. Installation is done one side at a time.

3. Remove the front tires and wheels.

4. Remove both of the front sway bar end links using a 15mm wrench for the upper and a 18mm wrench for the lower. Retain lower link hardware for re-use.

5. Place a floor jack underneath the axle for support and complete the removal of the front shock absorbers. Retain the stock lower hardware for reuse.

6. Do not reuse the original factory shocks.

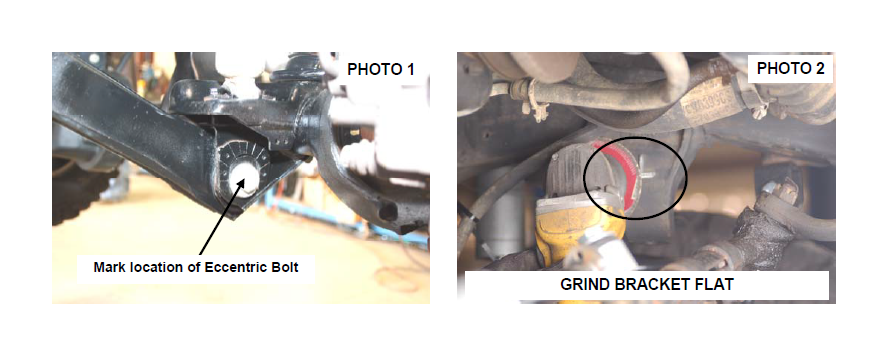

7. If your axle is equipped, mark the position of the lower control arm cam bolt and axle brackets for installation reference. See Photo 1. If equipped with ABS brakes, remove the sensor wires and clamps from the inside of the lower arms and save clamps for re-use.

8. Remove the track rod from the axle using a 15mm and from the frame using 18mm wrench.

9. If needed, grind the back side of the mount smooth to allow the track rod bracket to be installed. See Photo 2.

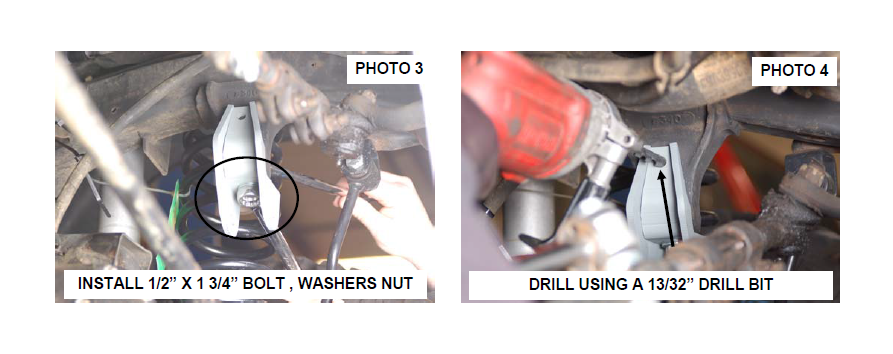

10.Install the new track rod bracket on the frame as shown in Photo 3 using the supplied 1/2” x 1 3/4” bolt, washers & nut in the stock track rod mount. Tighten using a 19mm Socket & wrench. View from the passenger side.

11.Using the bracket as a guide, drill the upper hole using a 13/32” drill bit. See Photo 4.

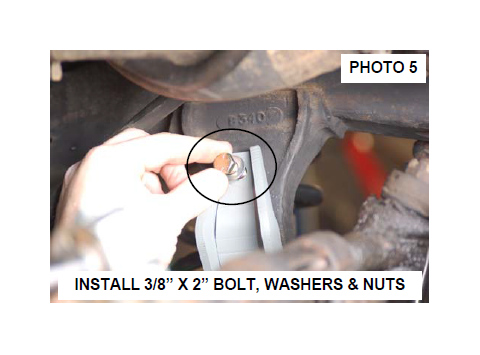

12. Install the supplied 3/8” x 2” bolt in the drilled hole with the washers & nut. Tighten using a 9/16” socket &

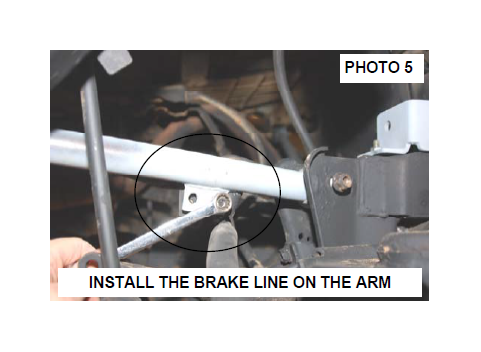

wrench. See Photo 5.

13. Remove the coil spring clip located on the bottom coil seat on the driver side and passenger side of the vehicle if equipped. Lower the axle and remove the coil spring. On some vehicles a coil spring or strut compressor may be needed to remove the stock coil spring.

14. Remove the stock lower control arm by removing the nut, cam, and cam bolt (if equipped) from the axle bracket and then removing the nut and bolt from the frame bracket doing one side at a time using a 21mm socket & wrench. Retain hardware for reuse.

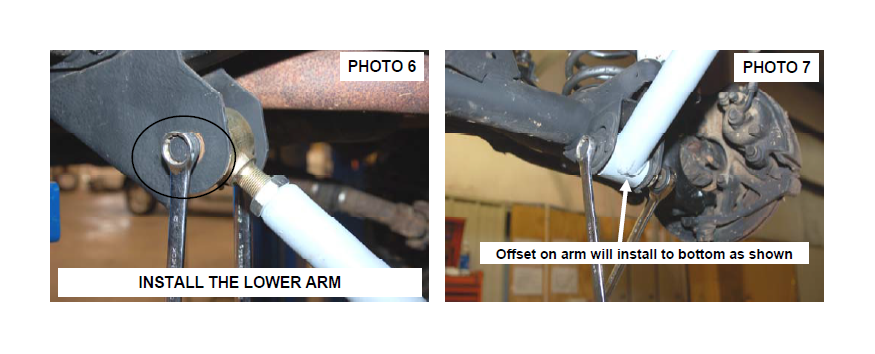

15. Lubricate control arm bushings with a lithium grease or equivalent and install in the Rough Country control arm. Adjust the arms to 3/8” longer then the stock arm for a

pre-alignment starting point. Tighten the jam nut using a 1 7/8” wrench. Check to make sure the snap ring is fully engaged on the joint and install on the vehicle making sure the joint is centered in the mount with the offset to the bottom using factory hardware as shown in Photo 6 & 7. Do not tighten at this time. If applicable, drill a 23/64” hole into each lower link and reinstall the ABS sensor wires. Use the original clamps. Adjust arms only as needed for alignment purposes. Do not over adjust the arms.

16. Remove the stock upper control arm by removing the factory hardware from the axle & frame bracket using a 15mm wrench one side at a time.

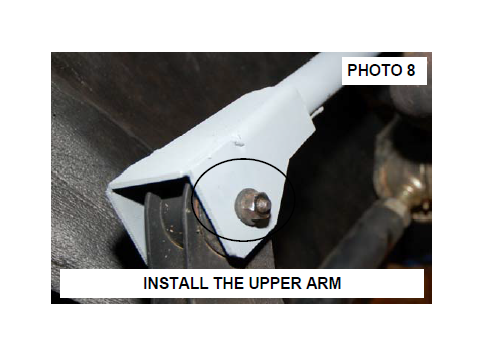

17. Lubricate bushings with a lithium grease or equivalent and install the new bushings and sleeves in the Rough Country control arm. Adjust arm to a 1/4” longer then the stock arm for a pre-alignment starting point. Tighten the jam nut using a 1 1/8” wrench. Make sure the snap ring is fully engaged on the joint and install arm on the vehicle using factory hardware making sure the joint is centered in the mount. Do not tighten at this time. See Photo 8. Adjust arms only as need for alignment purposes. Do not over adjust the arms

18. Install the coil spring. A coil spring or strut compressor may be needed for the new coil spring installation. If needed , compress the new coil spring and install the new spring into the upper and lower spring pockets. If used, carefully remove the compressor and make sure the coil is seated properly in the coil seat by rotating

the spring so the pig tail end fits in the spring pocket. Install the coil spring clamp and torque the spring clip bolt to 16ft.-lbs.

19. Repeat steps on other side.

20.Remove both of the front sway bar end links using a T55 Torx bit and 18mm wrench.

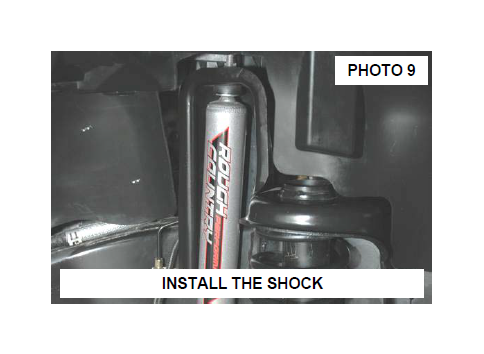

21.Locate the front 2.2 Series shock absorber and install in the factory lower mounts—these shocks are designed to have piston mounted down/ Body up. See Photo 9.

22.Install the new upper stud bushings on the shock absorbers and tighten the upper mounting point using a 9/16” wrench, slightly bulging the bushing. Do not over tighten stud bushing. Tighten the bar pin on the bottom of the shock with the stock hardware using a 12mm wrench.

23.Repeat this on the opposite side of the vehicle.

24.Install the tires, wheels and tighten lug nuts to factory

specs.

25.Lower the vehicle to the ground.

26.Install the supplied heim end, spacers and jam nut on the track rod body and install the bushings. Adjust the track rod to approx 31 3/4” from end to end.

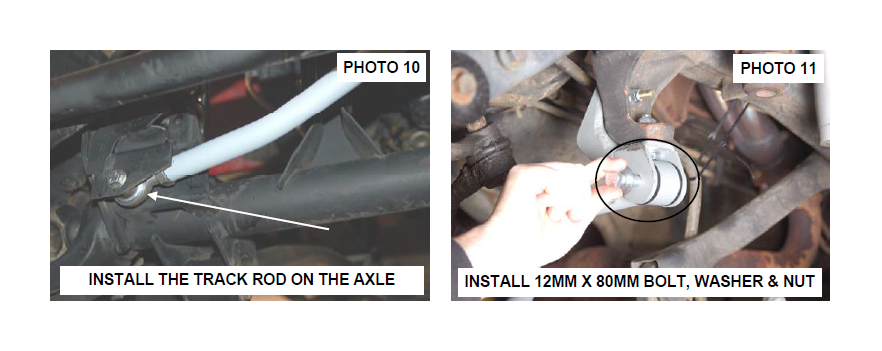

27.Install the heim joint on the track rod body with the supplied spacers on the heim joint and install in the factory mount on the axle with the supplied 7/16” x 2 3/4” bolt, washers & nut. Tighten using a 15mm socket / wrench. See Photo 10.

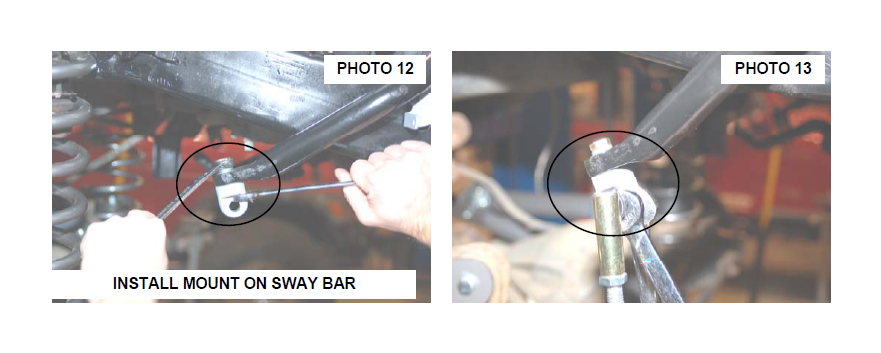

28.Swing up the track rod and install in the new track rod bracket with the supplied 12mm x 80mm bolt, washer and nut. Tighten using a 18mm wrench and snug the jam nut using a 1 1/2” wrench. See Photo 11. It is important to center the vehicle over the axle to ensure proper tracking and alignment. After install is completed, make sure the body is centered. If needed, remove the axle end and adjust to center the body over the axle.

29.Install the upper sway bar mount on the top of front sway bar where the stock link was secured, using the supplied 3/8” x 1.25” bolt and washer. Tighten using a 9/16” wrench making sure the mount is straight. See Photo 12.

30.Assemble the sway bar link with the link body, the jam nut and rod end Adjust the sway bar to a length of 10 1/4” from top to bottom. Tighten the jam nut against the rod end using a 5/8” & 3/4”wrench.

31.Install the link on the upper sway bar mount with supplied 1/2” flange lock nut as shown in Photo 13. Tighten using a 5/8” & 3/4” wrench.

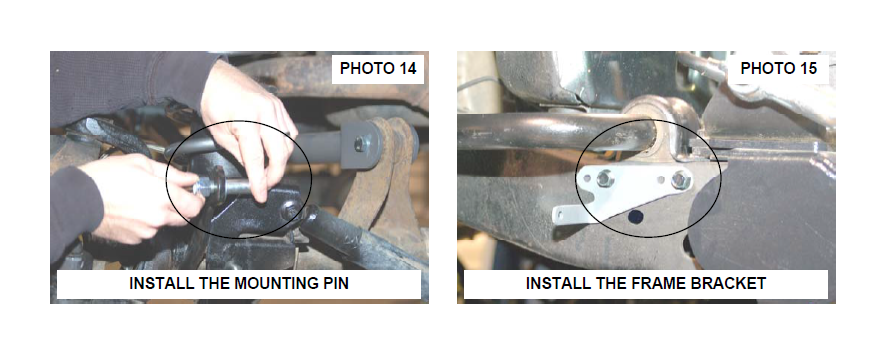

32.Install the supplied pin on the axle as shown in Photo 14. Tighten using a 3/4” wrench.

33.Remove the bolts securing the plastic shroud to the frame and install the driver and passenger side frame mount brackets in the holes shown for the 2 1/2” disconnect kit using the factory holes and the supplied 1/4” x 3/4” bolts & washers. See Photo 4. Tighten using a 7/16” wrench, be careful to not over tighten. Please note there is a

passenger and driver side bracket.

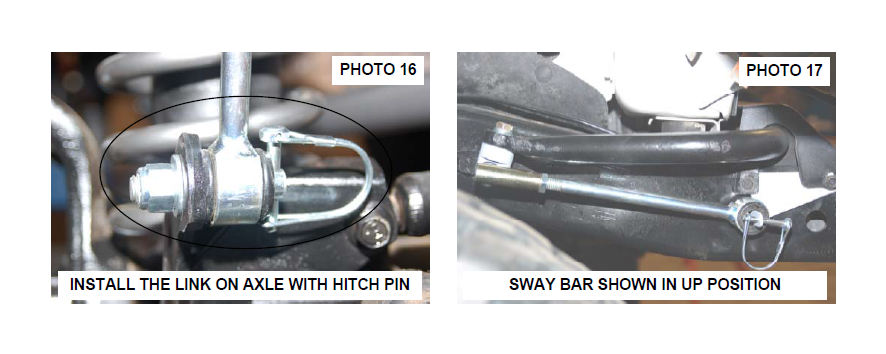

34.Swing the sway bar link down and install on the lower axle mounting pin. Install the disconnect pin. See Photo 16.

35.When disconnecting the sway bar, remove the sway bar link and place it on the frame mount with the hitch pin as shown in Photo 17 to keep the sway bar link from interfering with front end components.

36.Tighten the lower suspension arm to frame bracket nut and bolt to 65 ft. lbs. (both sides).

37.Align the reference marks on the adjustment cams and lower arm axle brackets and tighten to 85 ft. lbs.

REAR INSTALLATION

1. Chock the front wheels. Jack up the rear of the vehicle and remove the tires and wheels.

2. Place jack stands on the frame rail to support the vehicle. Place a floor jack under the differential.

3. Remove the stock shock absorbers using a 15mm socket on the upper bar pin and a 18mm wrench on the axle mount . Retain the factory shock hardware for reuse.

4. Remove the factory sway bar links using a 13mm socket / wrench. Retain sway bar hardware and links for reuse.

5. Carefully lower the axle with the floor jack and remove the coil springs. NOTE: It may be necessary to use a coil spring or strut compressor to remove the stock coil springs. Be careful not to overextend the vent tube on the axle. It may be necessary to disconnect the hose during installation and reroute after installation.

6. Disconnect the track bar from the axle bracket on driver side of vehicle using a T55 Torx bit. Retain hardware for reuse.

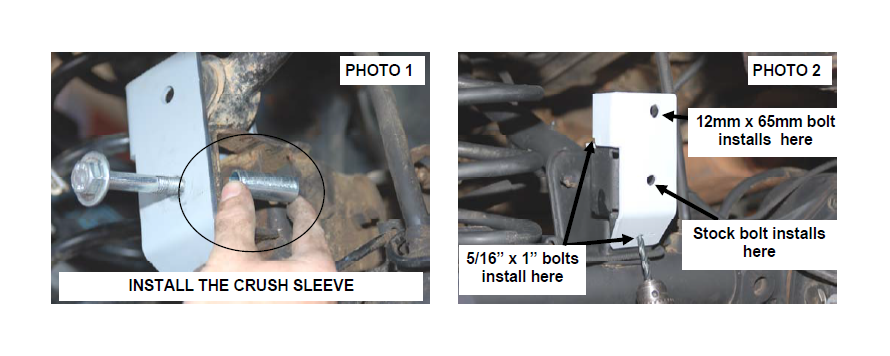

7. Install the new track bar relocation bracket in the stock location with the supplied crush sleeve. See Photo 1. Secure using the factory hardware in the factory location.

8. Using a drill and 11/32” drill bit enlarge the two factory holes in the factory mount as shown in Photo 2 and install the 5/16” X 1” bolts, washers, nuts. Tighten using 1/2” wrench to 15 ft/lbs. Do not install the track rod in the new bracket at this time.

9. Remove and replace one suspension arm at a time.

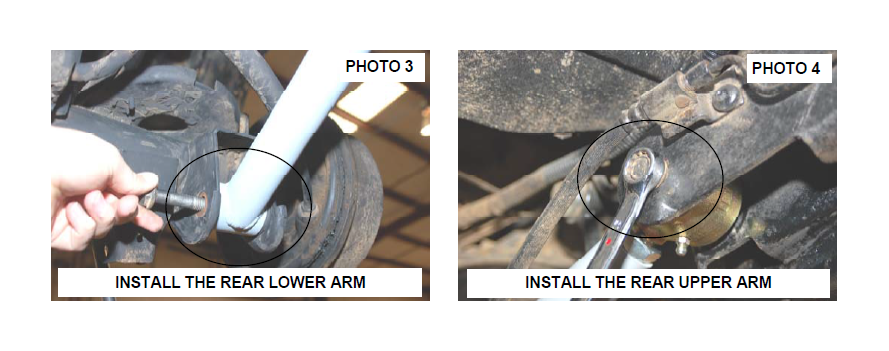

10. Remove the lower arm from the axle and frame mount using a 21mm wrench & socket. Retain hardware.

11. Lubricate control arm bushings with a lithium grease or equivalent and install in the Rough Country control arm. Adjust to a 3/8” longer then the stock arm for a pre-alignment starting point. Tighten the jam nut using a 1 7/8” wrench. Check to make sure the snap ring is fully engaged on the joint and install on the vehicle making sure the joint is centered in the mount and with the offset to the bottom using factory hardware as shown in Photo 3. Adjust arms only as need for alignment purposes. Do not over adjust the arms.

12. Repeat these steps on the other side.

13. Remove the rear upper stock control arms from both the frame and axle mounts using a 15mm socket & wrench. Retain the stock hardware for reuse. Remove the emergency brake line bracket from the stock control arm using a 1/2” wrench. Retain hardware for reuse.

14. Lubricate bushings with a lithium grease or equivalent and install the bushings and sleeves in the upper rear control arms.

15. Adjust the control arm to a length of 3/4” longer then stock arms (1/4” if using stock drive shaft) for a prealignment starting point. Check to make sure the snap ring is fully engaged on the joint and install the adjustable arms in the stock location making sure the joint is centered in the mount and reuse factory hardware to install. Do not tighten at this time. See Photo 4. Adjust arms only as need for alignment purposes. Do not over adjust the arms. Tighten jam nut using a 1 1/8” wrench.

16. Reinstall the emergency brake bracket onto tab on upper control arm. Reuse factory hardware and tighten using a 1/2” wrench. See Photo 5.

17. Install the new Rough Country coil springs making sure the rubber isolator in positioned in the upper mount. It may be necessary to use a coil spring or strut compressor to install the new coil springs.

18. Jack up the axle to compress the coil spring and to align the track rod with the new mounting point.

19. Install the track rod in the new bracket using the supplied 12mm x 65mm bolt and flange lock nut. No washer is needed at this mounting location.

20. Install the rear Rough Country 2.2 Shock absorber Part #660576 on the upper mount and install on the lower shock mounts with the factory hardware. Tighten using a 15mm & 18mm wrench. RCX 2.2 Series shock absorbers are designed to be installed with the piston down and body up.

21. Reinstall the wheels and tires. Lower the vehicle to the ground and tighten the lug nuts to the factory specifications using crossing pattern (80-110 ft. lbs).

22. Reinstall the factory sway bar links with the factory

hardware.

23. Tighten lower arm pivot bolts to 130 ft. lbs using a 21mm wrench & socket and the rear track bar mounting bolts to 74 ft. lbs. using a 18mm wrench.

24. Double check all hardware, torque as necessary.

POST INSTALLATION

1. Have a qualified alignment center realign front end to factory specs. As a general rule you set caster to the minimum of the factory spec and set toe-in to the maximum.

2. Install Warning to Driver decal on sun visor.

3. Adjust headlights to proper settings

4. All components must be retightened after 500 miles, and every three thousand miles

after installation.