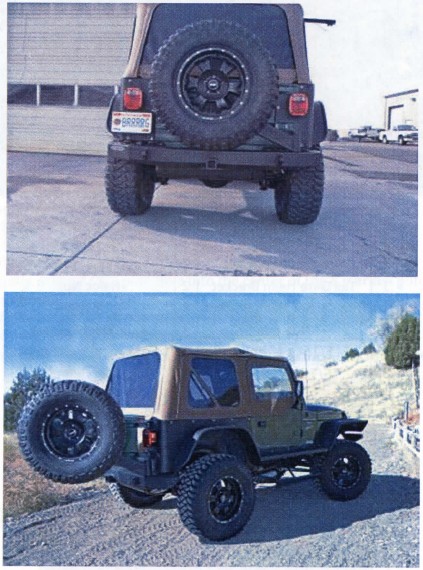

How to Install Rock-Slide Engineering Complete Rear Bumper (97-06 Wrangler TJ) on your Jeep Wrangler

TJ REAR BUMPER INSTALLATION

1. Remove stock bumper and spare tire carrier. Set aside all of the hardware. a. The tire carrier (8) bolts will be REUSED

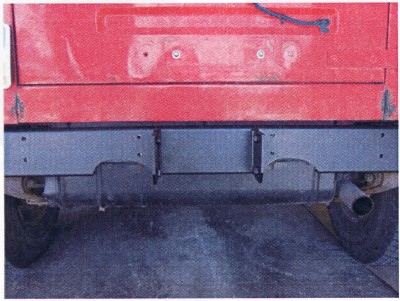

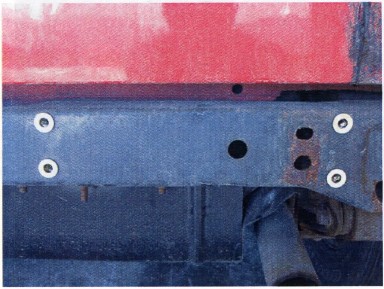

2. Position the 1st section of the bumper on the rear end and line up it up.

a. Mark the center holes on the bumper on the frame cross member in order to drill holes for nutserts

b. Set the bumper fram down.

3. Install the nutserts

a. Carefully drill a 7/32" pilot hole into the center of the 8 marked points on frame cross member

b. From the center of the pilot hole, step up the hole size using a 1/2" bit to create a finish hole that will be used to install the nutserts

c. Install the 8 nutserts in the holes that were just drilled into the frame cross member

d. We suggest using a crimping tool to optimize the integrity of the nutserts to support the slider

e. If no crimping tool is available, follow these instructions

i. Install by using a 5/16"x1.125" minimum length bolt with a 3/8" nut

ii. Put a small amount of grease on the bolt to reduce friction

iii. Hold the nut steady with an end wrench so the flange of the insert is flush against the cross member

iv. Tighten the bolt against the nut to crimp the nutsert into place

v. If the nutsert is rotating, place a star-lock washer between the 3/8" nut and nutsert

vi. Once the nutsert is crimped into place completely back out the bolt

vii. If the nutsert ever breaks loose and spins, repeat the process and crimp it tighter to prevent spinning

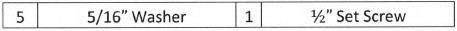

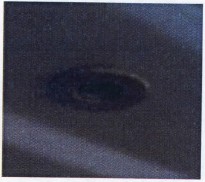

Completed nutserts should look like this

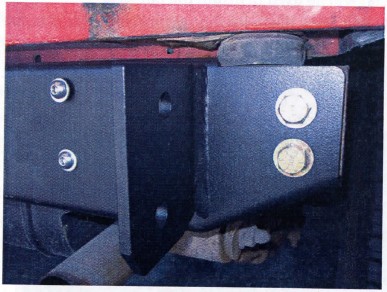

4. Attach Bumper

a. Loosely attach ends sides

b. Attach the center of the bumper to the frame cross member that has nutserts.

c. Tighten all 8 5/16" bolts with washers to firmly attach bumper to Jeep.

d. Tighten end bolts to factory mounts on each side of the frame mount. **DO NOT forget to mount the bottom bolts that was removed also.

5. Mount 2nd piece of rear bumper to the installed half and bolt together using supplied 7/16" bolts and washers.

6. When installing the 2nd half of the bumper you will have to use a 12" socket extension to reach the mounting points under the bumper on the inner parts. These do not require nuts.

The bolts that you install on the outer ends of the bumper will need bolts and nag:4-

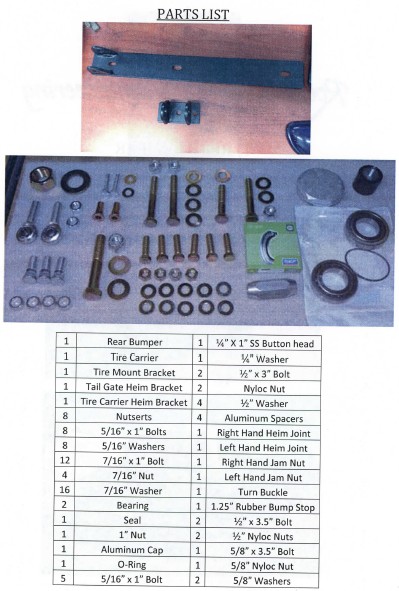

TIRE SWING INSTALLATION

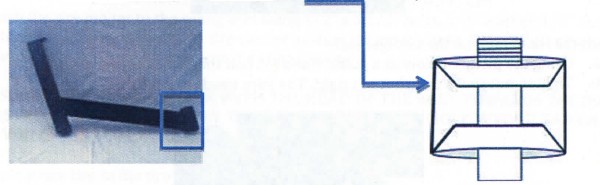

1. Install 2 bearing races into the tire swing mount.

a. The thick side of races MUST face inward

b. Installed correctly the top race has a taper that faces towards the ground, the bottom race taper points skyward (Diagram below illustrates)

2. With races installed correctly, pack the bottom bearing with grease and install it into the bottom of the tire carrier with the taper side up.

3. Install the seal by tapping it into the bottom of the tire carrier.

4. Slide the tire carrier, seal and bottom bearing over the bumper spindle.

5. Pack the upper bearing with grease and install it taper side down by sliding itover the treads on the bumper spindle.

6. Install 1 1" washer and 11" nut to secure tire carrier assembly.

a. Tighten the nut so there is no play in the assembly but loose enough thatthe tire carrier still operates in a smooth fashion

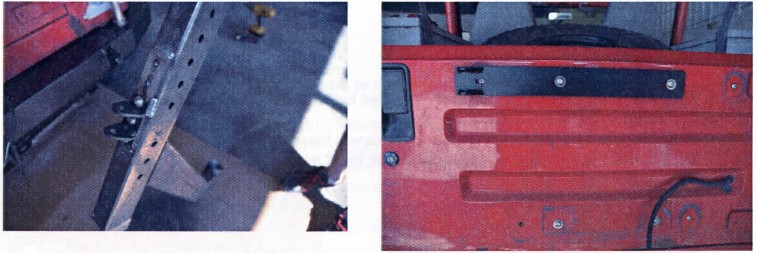

7. Place the 0-ring inside the aluminum cap and install it over tire carrier assembly.

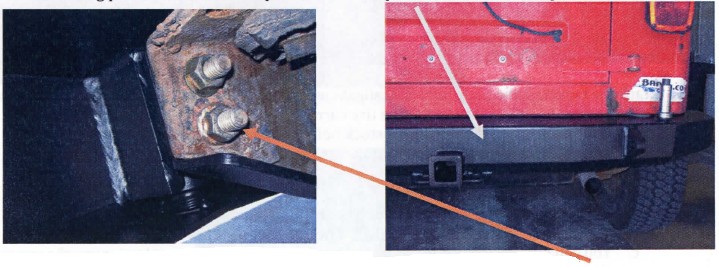

8. Attach the tailgate heim plate onto the tailgate using the stock bolts (pictured above) and attach the tire carrier heim joint bracket to the tire carrier.

a. You can reinstall the remaining stock bolts into their original positions

b. Leave the factory rubber bump stops attached to the tailgate

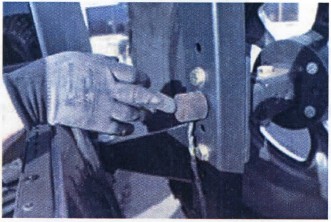

9. Attach Heim Joint on the tailgate side.

a. Using the picture below as a guide. Use a 1/2" bolt that 3" long for this.

b. Tighten nut so it's snug but not tight. The joint needs to have play

c. You can put the aluminum spacers in any given configuration as to giveyou the spacing that you need for things to clear.

10. Attach the Heim Joint on the swinger side.

a. Using the picture below as a guide, Use a 1/2" bolt that 3 1/2" long for this.

b. Tighten nut so it's snug but not tight. The joint needs to have play

11. Combine the tailgate and swinger sides using the turnbuckle

a. Use the spacers to make the turnbuckle as level as possible (see below)

12. Attach the rubber stopper to the back of the tire carrier swing at the hole below the top bolt (as seen below)

13. Pound the 3 lug studs into the tire mount.

a. Determine the best location for your tire size and lug nut pattern, also if you have a body lift that will change the location of your mounting points.

i. *Tire carrier is designed to accommodate up to a 39" tire

14. Attach the tire mount to the swing arm using 1/2" x 3 1/2" bolts, 1/2" washer,1/2" nuts

15. Tighten the 1/2" set screw on the tire carrier against the inner sleeve. Thiswill eliminate any movement or rattling that may occur during driving.

MAKE SURE TO PUT THE BOLTS IN WITH THE HEAD OF THE BOLT TOWARDS THE JEEP. IF YOU INSTALL THESE INCORRECTLY THE BOLT WILL PUNCH A HOLE INYOUR TAILGATE WHEN YOU CLOSE IT OR GO OFF-ROAD.

16. Attach spare tire to the tire mount.

17. Rotate the turnbuckle to take up any movement of the tire carrier.

a. Adjust the turnbuckle to ensure the spare tire carrier does not have any rattle

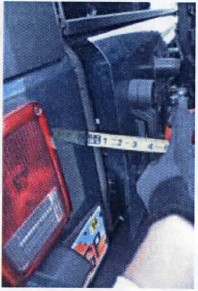

b. Make sure the arm rests snuggly against the rubber stopper when the tailgate is closed

c. When closing the tailgate, the rubber stopper on the swing arm should start to hit the tailgate when the tailgate is 2.25" from the body (see picture)

d. You should feel some pressure on the door just before it closes

e. ***Do not over tighten as this could cause the tire carrier swing arm to bend the tailgate***

f. When the tailgate is closed, the spare tire should have no loose movement. If it moves when you try to rattle it, tighten the turnbuckle more

g. **Take extra care that the tailgate opens and closes freely**

18. Perform a final check of all components to ensure proper fitment and torque.