How to Install ReadyLIFT 4 in. Lift Kit No Shocks w/ Brake Line Extensions on your Wrangler

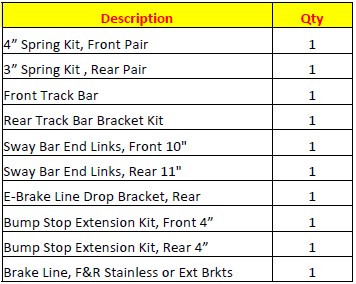

Bill of Materials

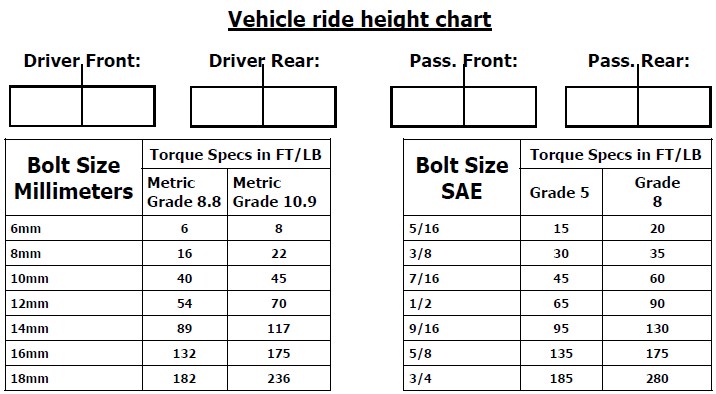

The Bill of Materials represents the component contents of this kit. All hardware is of the highest grade and the components are manufactured to exacting specifications for a trouble free installa-tion. Use the attached torque specifications chart when final tightening of the nut and bolts are done.

1. Lift the vehicle and remove the tires. Support the axles.

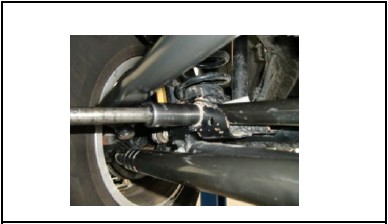

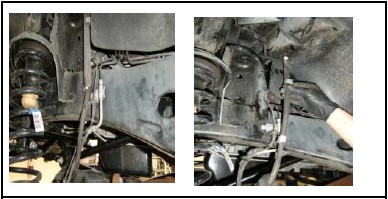

2. With the vehicle properly supported locate the front track bar.

3. Remove the track bar from the frame.

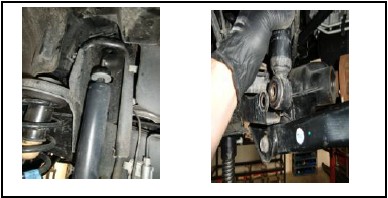

4. Next, unbolt the track bar from the axle and remove from vehicle.

5. Unbolt and remove the sway bar end links from vehicle.

6. Unbolt and dislodge the brake line brackets from the axle.

7. Remove the stock shocks off of the vehicle

8.

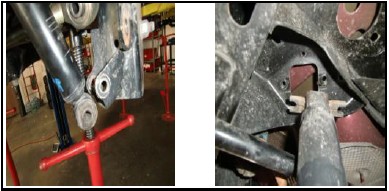

9. Unbolt the tie-rod from the spindle.

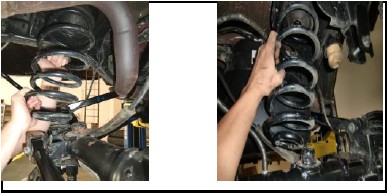

10. Lower the axle and remove the coil springs.

11. Center, mark and drill 7/16 hole.

12. Slip bump pad extension in the coil spring and install as complete assembly. Then tighten the bump extension bolt down using the hardware provided.

13. Install new extended length shocks.

14. Install new 10” sway bar end links with provided hardware. Note: Head of bolt must face to the inside of vehicle.

15. Install new adjustable track bar and torque down. Also re-install the tie-rod end and torque down.

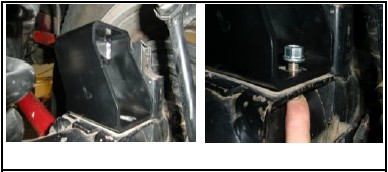

16. Unbolt the brake line and remove from vehicle. Remove old bracket and install the new Bracket. Bolt the bracket to the frame first, then install the line through bracket. Finish with the push on clip to hold brake line.

17. Brake lines are different for a pass. side & driver side, not universal. The bend goes toward the wheel. Route ABS wire properly. You must bleed brakes before the vehicle is driven.

18. Unbolt rear brake line bracket from bottom of the cab. Bolt the stock bracket to the drop bracket with supplied hardware.

19. Unbolt and remove the rear track bar. Support the rear axle.

20. Unbolt the rear sway bar end links and remove.

21. Unbolt and remove rear brake caliper and hang caliper out of the way.

22. Remove the rear shocks

23. Lower the rear axle and remove the springs.

24. Install new bump with supplied hardware. Bump stop pad should be leaning towards front of vehicle.

25. Install new coil with factory rubber boot on top.

26. Install rear track bar extension bracket with provided hardware and spacers.

27. Install the new track bar into the frame pocket and axle mount.

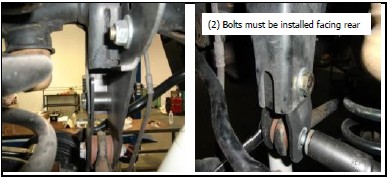

28. Install rear 11” sway bar end links with supplied hardware.

29. Re-install the brake calipers and torque.

30. Install Rear Brake lines & Brackets. Rear Brake lines/ Brackets are uni-versal (Either Left or Right) Make sure line is routed in a way to protect it from damage . (Brakes must be bleed before driving)

31. Install extended length rear shocks.

Re-install wheels and tires. Lower vehicle on to the ground and dou-ble check all work performed.

The install is complete and the VEHICLE MUST BE ALIGNED and brakes checked before driving. Once install is complete double check all work performed and verify the steering has full sweep left to right and the drive lines spin freely.

Final Checks & Adjustments

Post Installation Warnings: Once the vehicle is lowered to the ground, check all parts which have rubber or urethane com-ponents to insure proper torque. Torque wheels to factory specs. Move vehicle backwards and forwards a short distance to allow suspension components to adjust. Turn the front wheels completely left then right and verify adequate tire, wheel, brake line, and ABS wire clearance. Test and inspect steering, brake and suspension components for tightness and proper operation. Inspect brakes hoses and ABS lines for adequate slack at full extension. Failure to perform the post inspection checks may result in vehicle component damage and/or personal injury or death to driver and/or passengers. Test drive vehicle and re-check the torque of all fasteners and re-torque wheels on vehicle. Re-adjust headlamps.

Vehicle Handling Warning: Vehicles with larger tires and wheels will handle differently than stock vehicles. Take time to familiarize yourself with the handling of your vehicle.

Wheel Alignment/Headlamp Adjustment: It is necessary to have a proper and professional wheel alignment performed by a certified alignment techni-cian. Align the vehicle to factory specifications. It is recommended that your vehicle alignment be checked af-ter any off-road driving. In addition to your vehicle alignment, for your safety and others, it is necessary to check and adjust your vehicle headlamps for proper aim and alignment

Vehicle Re-Torque and Safety Inspection: Upon completion of all services and adjustments performed on your vehicle, and within 50 miles of driving, check to ensure all fasteners and hardware are properly torqued to specification as noted in the vehicles factory service manual or the torque chart included.