How to Install ReadyLIFT 4 in. Coil Spring Lift Kit w/ SST3000 Shocks (07-18 Wrangler JK) on your Jeep Wrangler

Shop Parts in this Guide

Safety Warning: Suspension systems or components that enhance the on and off-road performance of your vehicle may cause it to handle differently than it did from the factory. Extreme care must be used to prevent loss of control or vehicle rollover during abrupt maneuvers. Always operate your vehicle at reduced speeds to ensure your ability to control your vehicle under all driving conditions. Failure to drive safely may result in serious injury or death to driver and passengers. Driver and passengers must ALWAYS wear your seat belts, avoid quick sharp turns and other sudden maneuvers. ReadyLIFT Suspension Inc. does not recommend the combined use of suspension lifts, body lifts, or other lifting devices. You should never operate your vehicle under the influence of alcohol or drugs. Constant maintenance is required to keep your vehicle safe. Thoroughly inspect your vehicle before and after every off-road use.

Installation Warning: All steps and procedures described in these instructions were performed while the vehicle was properly supported on a two post vehicle lift with safety jacks. Use caution during all disassembly and assembly steps to insure suspension components are not over extended causing damage to any vehicle components and parts included in this kit. Included instructions are guidelines only for recommended procedures and are not meant to be definitive. Installer is responsible to insure a safe and controllable vehicle after performing modifications.

ReadyLIFT Suspension Inc. recommends the use of an OE Service Manual for model/year of vehicle when disassembly and assembly of factory and related components. Unless otherwise specified, tighten all bolts and fasteners to standard torque specifications listed within the OE Service Manual, or as referenced in the torque specification list provided in these instructions.

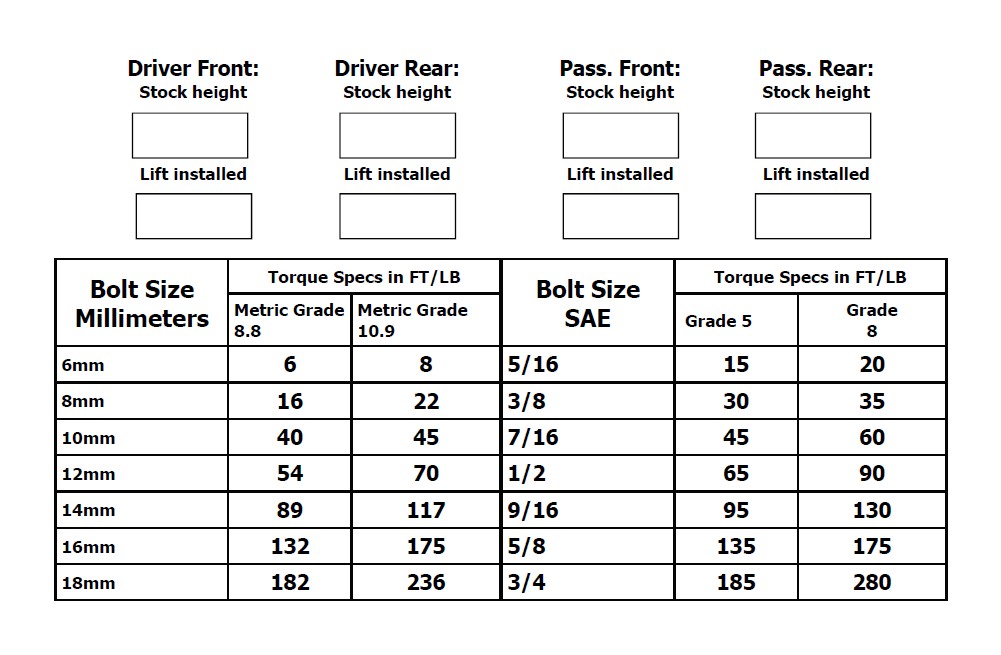

Suspension components that use rubber or urethane bushings should be tightened with the vehicle at normal ride height. This will prevent premature wear or failure of the bushing and maintain ride comfort. Larger tire and wheel combinations may increase leverage on suspension, steering, and related components. Due to payload options and initial ride height variances, the amount of lift is a base figure. Final ride height dimensions may vary in accordance to original vehicle ride height. Always measure the vehicle ride height prior to beginning installation.

Vehicle ride height chart

Securely raise vehicle off ground and remove (4)wheels

Support front axle and remove upper track bar bolt.

Remove (2) front transfer case skid plate bolts.

Disconnect dr./pass. lower front sway bar end links

Disconnect and remove front lower shock hardware.

Carefully lower front axle enough to remove front springs.

Center, mark and drill 11/32 hole for self tapping bolt.

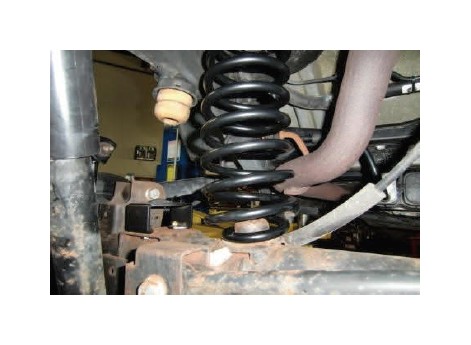

Install new springs/bumpstops extensions simultaneously.

Secure bumpstop extensions to axle with provided hardware.

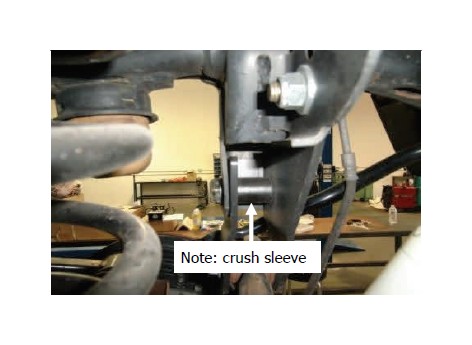

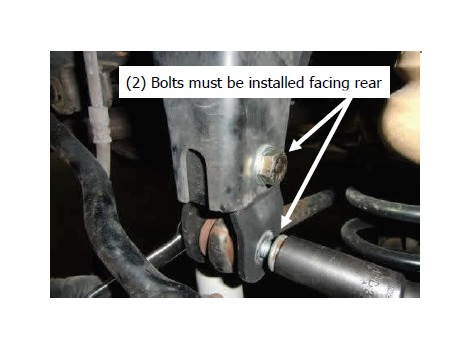

Install front lower shock extensions and torque to spec

Raise axle and reinstall OE front shocks and torque to spec.

Reinstall front transfer case skid plate bolts.

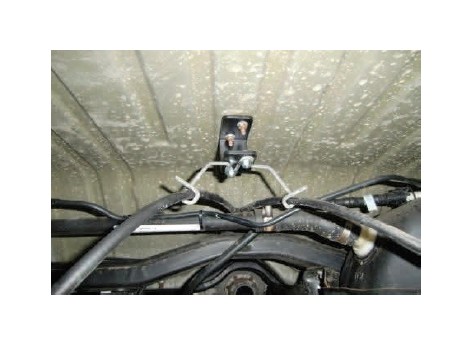

At the rear, remove center brake line nuts under body.

Install provided brake line extension bracket and hardware.

Disconnect and remove rear swaybar endlinks

Remove rear brake calipers.

Slightly lift rear axle and remove upper trac bar bolt.

Next, remove rear upper shock bolts.

Carefully lower rear axle and remove rear coil springs.

Install new upper trac bar bracket with provided hardware.

Install rear bump stop extensions with provided hardware.

Install new coil springs and OE isolators and raise axle.

Install upper shock extensions with provided hardware.

Reinstall rear brake calipers and torque to spec.

Carefully raise rear axle enough to reinstall upper track bar.

Attach new sway bar end links and hardware.

Reinstall wheels and tires and lower vehicle to ground.

Attach new front sway bar end links and hardware.

Reconnect front upper trac bar with OE hardware and torque.

Torque wheels to spec., test drive and get vehicle alignment.

Final Checks & Adjustments

Post Installation Warnings: Once the vehicle is lowered to the ground, check all parts which have rubber or urethane components to insure proper torque. Torque wheels to factory specs. Move vehicle backwards and forwards a short distance to allow suspension components to adjust. Turn the front wheels completely left then right and verify adequate tire, wheel, brake line, and ABS wire clearance. Test and inspect steering, brake and suspension components for tightness and proper operation. In-spect brakes hoses and ABS lines for adequate slack at full extension. Failure to perform the post in-spection checks may result in vehicle component damage and/or personal injury or death to driver and/ or passengers. Test drive vehicle and re-check the torque of all fasteners and re-torque wheels on vehi-cle. Re-adjust headlamps.

Vehicle Handling Warning: Vehicles with larger tires and wheels will handle differently than stock vehicles. Take time to familiarize yourself with the handling of your vehicle.

Wheel Alignment/Headlamp Adjustment:

It is necessary to have a proper and professional wheel alignment performed by a certified alignment technician. Align the vehicle to factory specifications. It is recommended that your vehicle alignment be checked after any off-road driving. In addition to your vehicle alignment, for your safety and others, it is necessary to check and adjust your vehicle head-lamps for proper aim and alignment

Vehicle Re-Torque and Safety Inspection:

Upon completion of all services and adjustments performed on your vehicle, and within 50 miles of driv-ing, check to ensure all fasteners and hardware are properly torqued to specification as noted in the vehicles factory service manual or the torque chart included.