3 Days Left! Guaranteed Free Delivery 12/24. Order by 3pm EST available on most items - Details

How to Install Poison Spyder RockBrawler II Rear Bumper w/ Tire Carrier - SpyderShell Armor Coat

Installation Time

2 hours

Tools Required

- Primer, paint, cleaners and masking materials (if painting)

- Mechanic’s tool set with a full assortment of SAE and metric end wrenches, sockets, ratchets, hex keys, etc.

- Drill Motor with 1/4” & 1/2” drill bits, and a 1” hole saw (or drill bit or step drill)

- Measuring tape or ruler

- Felt-tip fine point marker, scribe or punch

Shop Parts in this Guide

The Poison Spyder Customs RockBrawler™II Rear Bumper is easy to install with the right tools and good mechanical abilities. If you are not confident in your mechanical skills, please seek the help of a professional to perform the installation. Please read through these entire instructions before proceeding with installation.

PARTS LIST

(1) JK RockBrawler™ II Rear Bumper

(1) JK RockBrawler™ II Floating Mount Plate

(1) RockBrawler™ II Tire Carrier

(1) JK RockBrawler™ II Tailgate Plate

(1) RockBrawler™ II V-Alignment Plate

(1) 1/2” Black UHMW V-Alignment Bushing

(1) Tire Mount - Carrier Side

(1) Tire Mount - Tire Side

(1) License Plate Mount

(1) 3/8-24 LH/RH X 1-5/8 Alum Turnbuckle

(1) 3/8-24 X 2-1/8 RH Spherical Rod End

(1) 3/8-24 X 2-1/8 LH Spherical Rod End

(1) 3/8-24 SS Hex Nut RH Thread

(1) 3/8-24 SS Hex Nut LH Thread

(2) Tapered Roller Bearing with Race - Timken SET5

(1) Grease Seal - Timken #5121

(1) Billet Pivot Housing Cap

(1) Pivot Housing Cap O-Ring

(1) 1”-14 GrC All Metal Lock Nut

(1) 1” Flat Washer

(5) 3/8-16 X 3/4 Gr8 Hex Head Cap Screw

(4) 3/8-16 X 1 Gr8 Hex Head Cap Screw

(2) 3/8-16 X 1-3/4 Gr8 Hex Head Cap Screw

(10) 3/8 SAE Gr8 Flat Washer

(6) 3/8-16 Gr8 Nylon Insert Lock Nut

(4) 3/8-16 Clip Nut

(8) 7/16-14 X 1 Gr8 Hex Head Cap Screw

(16) 7/16 SAE Gr8 Flat Washer

(8) 7/16-14 Gr8 Nylon Insert Lock Nut

(4) 1/4-20 X 3/4 SS Button Head Cap Screw

(4) 1/4-20 X 1 SS Button Head Cap Screw

(2) 1/4-20 X 3/4 Gr8 Hex Head Cap Screw

(8) 1/4 Flat Washer

(4) 1/4 X 5/8 OD SS Flat Washer

(10) 1/4-20 Nylon Insert Lock Nut

(3) 12MM-1.5 Open Wheel Lug Nut

(3) 12MM-1.5 X 1-1/2” Wheel Lug Stud

BEFORE YOU BEGIN

The Poison Spyder Customs RockBrawler™ II Rear Bumper comes as unpainted, bare steel. You will want to either powder coat or paint the bumper prior to final installation. If painting yourself, careful preparation will make a big difference in the quality and longevity of your paint job, even using “rattle can” aerosol paints. Begin by thoroughly cleaning the bumper with solvent or de-greaser, then make sure all residue is removed. Even if you use cheap paint, try to use a good quality primer. “Etching” primers are best to use on bare, unpainted metal. Allow it to properly dry before painting, and between paint coats.

INSTALLATION PROCEDURE

1. Park the Jeep on a flat, level surface and set the parking brake.

2. Remove existing rear bumper and disconnect the rear sway bar where it bolts to the outside of the frame rails. Keep the OE hardware that attached the bumper to the frame rails, as some of it will be re-used.

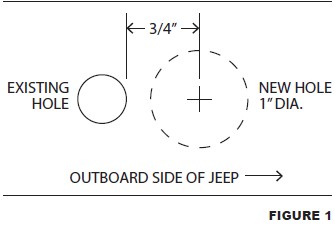

3. Look along the underside of the Jeep’s rear crossmember to locate two small holes, just a few inches inboard from the frame rail at either end. Measure 3/4” outboard from the edge of the existing hole and either centerpunch or use a felt-tip pen to make a mark (as shown in Figure 1). Use a hole saw, drill bit or step drill to make a 1” hole centered on this mark. Repeat for the opposite side, making sure the new hole is outboard of the existing hole on eithr side.

4. Apply touch-up paint to the bare metal around the edges of the holes that were drilled in the previous step. Properly coating these areas at this time will help to prevent rust in the future.

5. Insert a 3/8-16 Clip Nut through the new 1” hole, and clip it into the pre-existing hole. Make sure the extruded thread barrel of the clip nut points inward. Do this at both of the hole locations along the underside of the crossmember.

6. Install the Floating Mount Plate to the Driver side of the RockBrawler™ II rear bumper using the supplied hardware. Leave the fasteners finger-tight, so the plate may be further adjusted.

7. With the help of a friend, pre-install the RockBrawler™ II rear bumper on to the Jeep. The bolt flange of the RockBrawler™ II bumper will mount between the outside of the frame rail and the sway bar bracket. Note that there are three bolt holes in the bolt flange on each side of the bumper. Two of these bolt holes will align with the stock bolt holes in the frame rail, where the sway bar bracket attaches. Use the OE hardware to secure the bumper in place using these two bolt locations on either side. On the driver side with the Floating Mount Plate, tighten the hardware attaching the plate to the bumper, after ensuring that the bumper is properly centered and aligned.

8. Use a felt-tip pen or 3/8 center punch to mark the location of the third bolt hole on the frame rail, for each side. Then remove the bumper.

9. Drill the third bolt hole on each side to 1/2”. It is best to start with a smaller drill size such as 1/4”, then step up to the 1/2” size bit.

10. Apply touch-up paint to the bare metal around the edge of the holes that were drilled in the previous step. Properly coating these areas at this time will help to prevent rust in the future.

11. Insert a 3/8-16 Clip Nut through the oblongshaped hole in the frame rail, and clip it into the new hole just drilled. Make sure the extruded thread barrel of the clip nut points inward. Do this on both frame rails.

12. Reinstall the RockBrawler™ II bumper using the OE hardware in the two original bolt locations on the sides of the frame rail, and a supplied 3/8-16 X 1 Gr8 Hex Head Cap Screw with 3/8 Flat Washer in each of the new bolt locations on the outside of the frame rails and under the crossmember (where the Clip Nuts were installed in the previous steps). Again, note that both the stationary mount flange and Floating Mount Plate are inserted between the outside of the frame rail and the sway bar bracket.

13. Torque the eight bolts (3 on each side and two underneath) to 45 ft.-lbs.

14. If the optional 2-1/2” LED backup lamps were purchased, use the provided rubber grommets to mount them into the recessed mounting flanges inside the backup lamp buckets. Use the electrical pigtails that came with the lamps, along with wire and connectors (not included) to wire the backup lamps in to your Jeep’s backup lamp circuit.

15. Use the OE Spare Tire Mount hardware to attach the Tailgate Plate to the tailgate. The TailGate Plate must be oriented so the welded-on brackets are toward the top and driver side.

16. Wearing latex or nitrile gloves, “Pack” the two tapered roller bearings with a quality wheel bearing grease by hand or with a bearing packing tool. The two matching bearing races are already pressed in to the tire carrier hinge housing.

17. Wearing a latex or nitrile glove, use your fingers to apply a light sheen of grease to the bare metal surfaces of the inside of the tire carrier hinge housing and bearing races, as well as the hinge spindle on the bumper (do not coat the threads for the spindle nut). This will help discourage rust formation on these bare metal surfaces.

18. Insert a Tapered Roller Bearing into the pre-installed Lower Race, inside the Hinge Housing. Ensure that it seats correctly and “feels right” in the race. Excess grease may hold it in place temporarily, but it may be helpful to turn the tire carrier upside down until the next step is completed.

19. Use a bearing seal driver tool to carefully install the grease seal into the bottom of the hinge housing. If the proper tool is not available, the step may be performed by carefully using a large socket of the approximate diameter of the seal and a soft dead-blow hammer to work the seal into its seat. Be very careful to drive the seal in evenly, do not let it get misaligned while driving it in.

20. Install the Tire Carrier onto the bumper, carefully guiding the hinge housing down over the hinge spindle. Be careful not to damage the grease seal when lowering the tire carrier on to the spindle. There is a very tight-tolerance slip-fit between inner diameter of the tapered roller bearing and its seating surface on the spindle. Be careful not to let the bearing get misaligned as you lower the carrier onto the bumper. Have a friend support the opposite end of the tire carrier during this and the next two steps.

21. Install the remaining Tapered Roller Bearing by dropping it down over the hinge spindle, narrow end pointed downward. Carefully slide it down the spindle until it is seated into the upper race.

22. Apply some anti-sieze thread lubricant to the threads on the spindle. Install the large 1” Flat Washer next on the spindle, followed by the 1”-14 Grade C All-Metal Lock Nut. Tighten the lock nut until it just touches the washer and bearing, then have your friend slowly swing the tire carrier back and forth as you tighten the lock nut the rest of the way. We can not supply a torque specification for this nut, just get it as tight as it takes to properly seat the bearings and provide smooth operation of the tire swing without any “play”. You may need to re-tighten this nut several times until it permanently seats.

23. Install the Hinge Cap O-Ring onto the outside of the threads of the Billet Hinge Cap, just under the head of the cap (NOTE: this may have already been done prior to shipment).

24. Thread the Hinge Cap onto the Hinge Housing and lightly tighten with a 2-12” wrench, socket with ratchet or big-ass crescent wrench. Note that you may have to remove it in later steps to further tighten the spindle lock nut, so don’t fully tighten the cap until installation is complete.

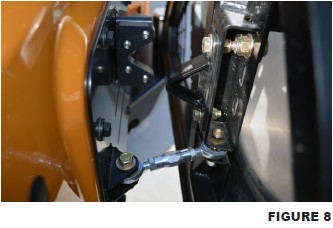

25. Install the 1/2” Black UHMW V-Alignment Bushing on to the corresponding bracket on the Tailgate Plate using the supplied hardware, as shown in Figure 8.

26. Install the V-Alignment Plate on to the back side of the Tire Carrier using the supplied hardware, as shown in Figure 8. Test that it seats correctly into the V-Alignment Bushing on the Tailgate Plate when the Tire Carrier is closed against the tailgate. Adjust as necessary then tighten all fasteners.

27. Assemble the Aluminum Turnbuckle, Spherical Rod Ends and SS Nuts into a tierod assembly. Note that there are left hand threaded and right hand threaded ends of the turnbuckle, rod ends and nuts, Use the provided hardware to attach one end of the tie rod to the Tailgate Plate, and the other end to the corresponding tabs in the back side of the Tire Carrier, as shown in Figure 8.

28. Leave the nuts on the tie rod loose, and adjust the length of the tie rod by rotating the turnbuckle. Adjust the length so that the V-Alginment Plate just begins to touch the V-Alignment Bushing when the tailgate is about 1/2” from being fully closed and latched, as shown in Figure 9. This is approximately the point at which the tailgate begins to compress the weatherstripping as it closes. With the tie rod adjusted thusly, test it by firmly (but carefully) closing the tailgate all the way, until it latches. When properly adjusted, this will result in the tie rod firmly pulling the V-Alignment Plate into the V-Bushing, and holding it there with enough pre-load to keep everything tight while the tailgate is shut. Once the tie rod has been properly adjusted, tighten both jam nuts.

29. Measure the overall height of your spare tire (NOT one of the mounted tires on your Jeep!), divide that measurement in half, then add one inch. The resulting number will be your tire mount height measurement. With the Tire Carrier closed and latched, measure upward from the recessed step surface of the bumper, and make a small mark on the tire carrier at the tire mount height measurement.

30. Use (4) 7/16-18 x 1 Gr8 Hex Head Cap Screws with (4) 7/16 Flat Washers and (4) 7/16-18 Nylon Insert Lock Nuts to attach the Tire Mount - Carrier Side to the Tire Carrier, centered on the mark you made in the previous step. The slots in the tire carrier allow for some adjustment, however if there isn’t enough adjustment to center the Tire Mount exactly centered on your mark, move it up slightly to the next set of slotted holes in the carrier.

31. Hold the Tire Mount - Tire Side up against the back side of your spare tire, with the short end of the square tube protruding through the hole in the wheel. Visually align the holes in the mounting plate with at least three holes in the wheel, while keeping the mounting plate centered. There are more than three holes in the mounting plate, to allow for a variety of wheel lug patterns to be used. Once three holes are correctly aligned, mark them with a felt-tip marker.

32. Use a shop press or hammer to drive the three provided Wheel Studs into the mounting plate. Make sure the studs point away from the long section of square tube (with the slotted hole).

33. Fit the Tire Mount - Tire Side channel on to the corresponding beam of the Tire Mount - Carrier Side. Use (2) 7/16-18 X 3 Gr8 Hex Head Cap Screws with (4) 7/16 Flat Washers and (2) 7/16-18 Nylon Insert Lock Nuts to secure the Tire Mount-Tire Side to the Tire Mount - Carrier Side, using the slotted holes provided. Leave these fasteners loose at this time.

34. With the help of a friend, lift the spare tire onto the Tire Mount - Tire Side, and fit the previously installed lug studs through the holes in the wheel. Loosely thread the (3) Lug Nuts on to the studs, holding the tire on. Leave the Lug Nuts threaded on only about half way.

35. Push the Tire Mount - Tire Side inward toward the Tire Mount -Carrier Side, and fully tighten the two 7/16-18 cap screws and nuts that were installed in the previous step.

36. Finish tightening the (3) Lug Nuts. This will draw the sides of the tire tightly against the frame of the Tire Carrier, to prevent rattles and squeaks.

37. Use (4) 1/4-20 X 3/4 SS Button Head Cap Screws, (4) 1/4 Flat Washers and (4) 1/4-20 Nylon Insert Lock Nuts to fasten your license plate to the License Plate Mount.

38. Use the 1/4-20 X 3/4 Hex Head Cap Screws with 1/4 Flat Washer and 1/4-20 Wing Nut to fasten the License Plate Mount to the Tire Mount at the center of the spare tire. Note that you will need to keep these wrenches available in the vehicle in order to remove the license plate mount to access your spare tire in the future.

39. Once the entire bumper is mounted and tested for proper operation, remove and disassemble the bumper for paint or powder coat. If painting yourself, careful preparation will make a big difference in the quality and longevity of your paint job, even using “rattle can” aerosol paints. Begin by thoroughly cleaning the bumper with solvent or de-greaser, then make sure all residue is removed. Even if you use cheap paint, try to use a good quality primer. “Etching” primers are best to use on bare, unpainted metal. Allow it to properly dry before painting, and between paint coats. Note that the Spyder Web Gusset Detail is detachable so that it may be painted or powder coated a contrasting color from the rest of the bumper.

If powder coating, make sure the entire bumper and tire carrier are completely disassembled first. Make sure the bearings, races and grease seal are not yet installed. Make sure your powdercoater understands that the hinge spindle must be masked off (not coated).

40. Once the bumper has been painted or powder coated, re-install by repeating the above steps.

Congratulations, you have completed installation of your RockBrawler™ II Rear Bumper and Tire Carrier!