How to Install Rugged Ridge Front & Rear Elite Ballistic Pro Seat Covers - Black on your 11-18 Jeep Wrangler JK; 2018 Jeep Wrangler JL

Shop Parts in this Guide

Parts Included (4): Front driver’s side seat cover with head rest and front passenger’s side seat cover with head rest.

Installation Instructions:

1. Lift driver’s side bar located under the seat that is near the floor, move seat forward, then lift recline lever to move seatback forward.

2. Press the two adjustment buttons, located on the base of the head restraint and raise the head rest up and off.

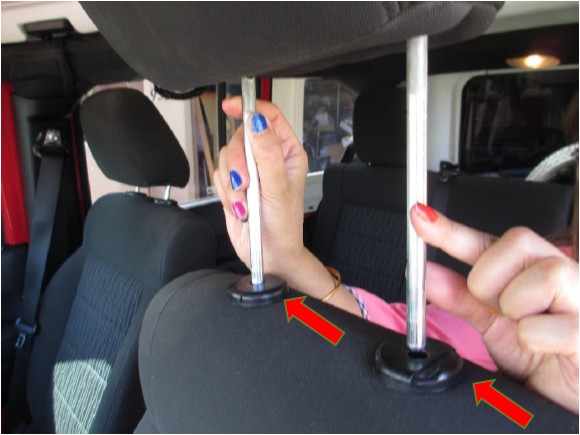

3. Slip one of the identical front, one piece, seat covers over top of the factory seat back and pull down tight. Fit top of seat cover over and under head rest brackets.

4. There are two sets of straps that connect front to back under the seat. Fish one strap between the cushions to the back. Fish the front strap under the seat and connect with the first strap below the seat. Repeat for the other front to back straps.

5. There is also one set of S hooks that connect side to side under the seat. Fish one side hook under the seat and connect with the other hook under the seat.

6. Fit and secure the two bottom side flaps with Velcro around the recline lever.

7. Pull head rest cover over factory head rest and secure with Velcro straps on bottom. The cover will only fit one way.

8. Insert headrest back into head rest brackets.

9. Repeat for other or passenger’s side Jeep Wrangler JK front seat.

10. Smooth out wrinkles and make final adjustments.

Installation Instructions Written by Extreme Customer Roger K Hedrick June 4, 2017