Guaranteed Free Delivery by 12/24! available on most items - Details

How to Install a JKS Rear Adjustable Trackbar over 3 In. Lift on your 1997-2006 Jeep Wrangler TJ

Installation Time

3 hours

Tools Required

- Hydraulic Floor Jack & Jack Stands

- Metric/Standard Socket Wrench Set

- Torque Wrench

- 1-1/2" Open-End Wrench

- T55 Torx Driver (for OE track bar bolt)

- Tape Measure

- Heavy Duty Ratchet Strap *

- Anti-Seize Lubricant

- Grease Gun with Zerk Fitting Coupler

- Wheel Bearing Grease

Welcome

CONGRATULATIONS on purchasing a new Adjustable Trackbar from JKS Manufacturing. We are committed to providing you with the best products available and your satisfaction is our first priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain important installation and maintenance information.

Important

VEHICLE MUST BE EQUIPPED with a CV type driveshaft if installing this product with angled relocation bracket on axle housing.

NOT COMPATIBLE WITH right hand drive vehicles.

CHECK TORQUE SPECIFICATIONS regularly.

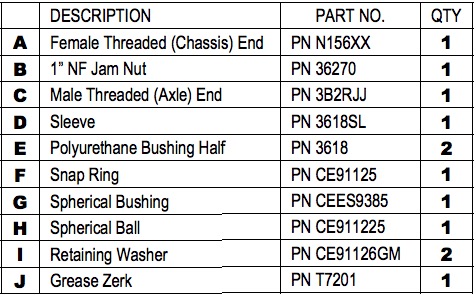

Parts

Installation

1. REMOVE REAR TRACK BAR

Raise and support vehicle chassis with jack stands positioned in front of the rear lower suspension arm brackets. Remove rear wheels from vehicle.

Raise and support axle housing with a hydraulic jack. HINT: To relieve tension from mounting bolts, axle should be evenly supported with suspension at normal ride height.

If equipped, remove and discard plastic dust shield covering the bolt that secures rear track bar to the OE bracket.

Remove rear track bar mounting hardware from axle and chassis brackets. HINT: A T55 Torx driver may be required to remove hardware.

Remove track bar from vehicle and retain hardware.

2. INSTALL ANGLED CV TRACK BAR BRACKET (OPTIONAL)

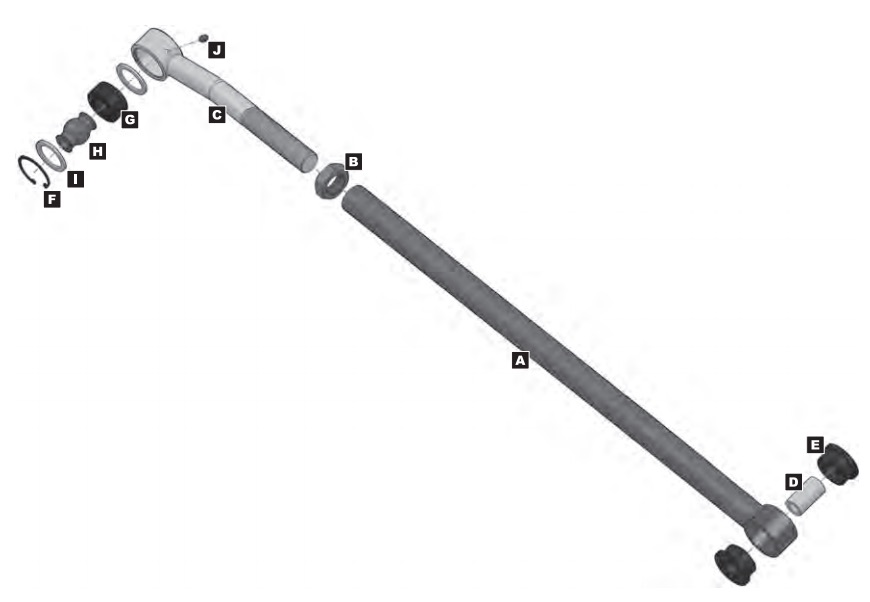

If Adjustable Trackbar PN OGS151B was purchased, a special Angled CV Bracket PN OGS160 was also supplied. The purpose of this bracket is to re-establish proper alignment of the axle bracket with the track bar. This is necessary whenever the axle is rotated to align the pinion with a CV type driveshaft.

If vehicle has already been equipped with a similar aftermarket angled track bar bracket, disregard this step and proceed to next section.

Install JKS Angled CV Track Bar Bracket PN OGS160 (or equivalent) at this time, according to the installation instructions provided with the part.

3. LUBRICATE BUSHINGS AT EACH END OF ADJUSTABLE TRACKBAR

Locate bag of parts containing Polyurethane Bushing Halves (E) and Sleeve (D).

Liberally apply wheel bearing grease to surface of bushings.

Assemble Polyurethane Bushing Halves (E) and Sleeve (D) at Chassis End (A) of track bar as indicated in the parts diagram on page 1.

Using a Grease Gun with Zerk Fitting Coupler, slowly inject wheel bearing grease into the Grease Zerk (J) at Axle End (C) of track bar.

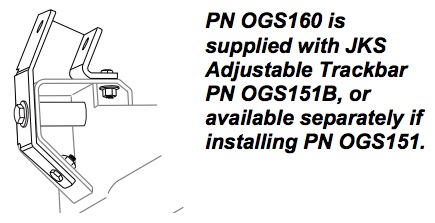

4. MOUNT ADJUSTABLE TRACKBAR TO CHASSIS RAIL BRACKET

Apply anti-seize lubricant to bolt threads of original track bar mounting hardware.

Mount Chassis End (A) of Adjustable Trackbar to the chassis rail bracket and loosely install the original mounting hardware. HINT: When installed correctly, the bend in Adjustable Trackbar should point up.

5. CENTER REAR AXLE HOUSING

The rear axle housing must be in perfect lateral alignment with vehicle chassis before Adjustable Trackbar installation can be completed.

Re-install wheels and lower vehicle to ground.

IMPORTANT: Vehicle must be at normal ride height, on level ground, with the suspension supporting the full vehicle weight.

Determine if the axle housing is centered by measuring the distance between the tire and chassis, using the exact same points on each side of the vehicle to ensure accuracy.

HINT: For example, measure from the edge of a tire tread lug to the outboard side of the chassis, then repeat the measurement on the other side of vehicle using exact same points.

If the two measurements are equal, the axle is centered. If the measurements vary, divide the difference in half to determine the amount of adjustment required.

HINT: If the axle housing is not centered, the chassis can be laterally shifted using either of the following methods.

Ratchet Strap (preferred)

Attach a heavy duty ratchet strap to the chassis on one side of the vehicle, and to the axle housing on the other side.

Slowly tighten the strap in small increments to pull the chassis in alignment with the axle. Take measurements after each adjustment until centered.

Pushing Vehicle Body

Although this method will laterally shift position of chassis relative to axle housing, it does not enable the position to be easily stabilized while measurements are taken.

With the vehicle safely on the ground, have a partner gently push on the vehicle body above the rear wheels.

6. SET ADJUSTABLE TRACKBAR LENGTH AND MOUNT TO AXLE

With the axle housing centered beneath the chassis, adjust the length of Adjustable Trackbar by rotating the Axle End (C) until the Spherical Ball (H) aligns with the mounting holes on the axle bracket.

Apply anti-seize lubricant to original mounting bolt threads and adjustment threads of trackbar.

Install Axle End (C) of Adjustable Trackbar to the axle bracket by securing with the original mounting hardware.

7. POST-INSTALLATION

Take measurements again to ensure axle housing is perfectly centered and make any final adjustments if necessary.

Once all adjustments are complete, fully tighten the Jam Nut (B) to prevent Adjustable Trackbar length from changing. HINT: It may be easier to tighten Jam Nut with the Adjustable Trackbar removed from the vehicle.

Using a torque wrench, tighten mounting hardware at both ends of track bar to 74 ft-lbs.

Maintenance

Re-torque fasteners after driving 150 miles. Continue to check torque specifications as part of regular vehicle maintenance routine.

The Axle End (C) of the Adjustable Trackbar features a spherical polyurethane bushing which is both greaseable and rebuildable.

Lubrication

Lubricate the bushing via the Grease Zerk (J) regularly as part of vehicle maintenance schedule. Use common wheel bearing grease or equivalent.

Replacement Parts

Bushings are designed for maximum longevity and it is extremely unlikely that any parts will wear out. Just in case, all replacement parts are available directly from JKS Manufacturing on our website at www.jksmfg.com.

Cleaning

Regular cleaning with pressurized water is recommended to maximize ease of operation and reliability. Always lubricate afterwards to evacuate any moisture

Welcome

CONGRATULATIONS on purchasing a new Angled CV Trackbar Bracket from JKS Manufacturing. We are committed to providing you with the best products available and your satisfaction is our first priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain important installation and maintenance information.

Important

VEHICLE MUST BE EQUIPPED with a CV type driveshaft.

NOT COMPATIBLE WITH right hand drive vehicles.

CHECK TORQUE SPECIFICATIONS regularly.

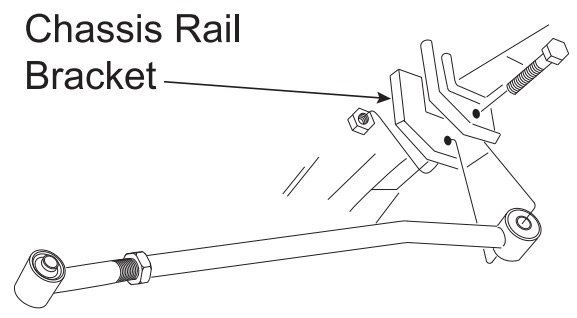

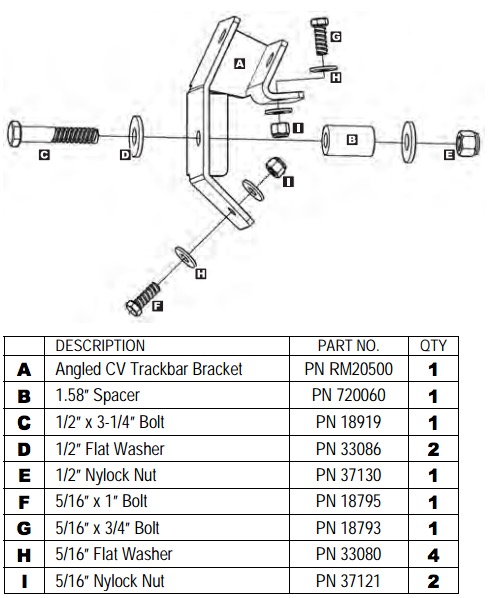

Parts

Tools Required

Hydraulic Floor Jack & Jack Stands

Metric/Standard Socket Wrench Set

Torque Wrench

T55 Torx Driver * (for OE track bar bolt)

5/16” Drill Bit

* Asterisk denotes tools that are not required for some applications. Thoroughly read instructions first to determine which tools will be required for your application.

Attention Installer

DO NOT INSTALL this product on vehicles that are equipped with a factory type “slip yoke” driveshaft with single cardan U-joints. This product is designed specifically for vehicles that have a CV type driveshaft with double cardan U-joint.

The CV type driveshaft requires the rear axle housing to be rotated to align the pinion with the driveshaft. The purpose of this Angled CV Bracket is to re-establish proper alignment of the axle bracket with the track bar.

Installation

1. REMOVE REAR TRACK BAR

Raise and support the vehicle chassis with jack stands positioned in front of the rear lower suspension arm brackets.

Remove the rear wheels from vehicle.

Raise and support the rear axle housing with a hydraulic jack.

HINT: The axle housing should be evenly supported, with the suspension at normal ride height to relieve any tension from the mounting bolts.

If equipped, remove and discard the plastic dust shield covering the bolt that secures the rear track bar to the OE bracket.

Remove the rear track bar mounting hardware from the axle bracket. Retain hardware.

HINT: A T55 Torx driver may be required to remove factory hardware.

Remove track bar from axle bracket pocket.

HINT: It may be necessary to remove the mounting hardware from the chassis bracket before track bar can be removed.

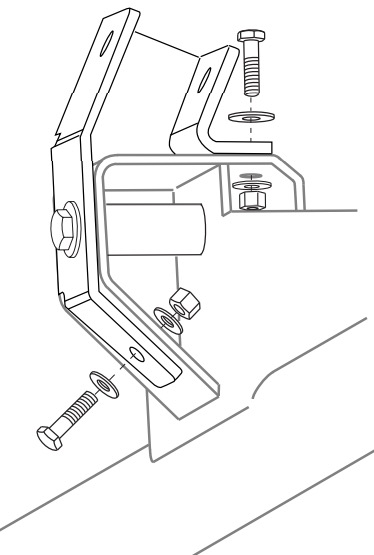

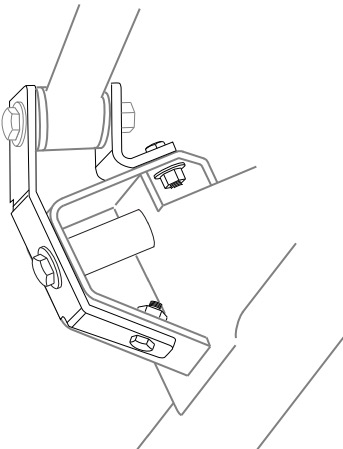

2. MOUNT ANGLED CV BRACKET TO AXLE HOUSING BRACKET

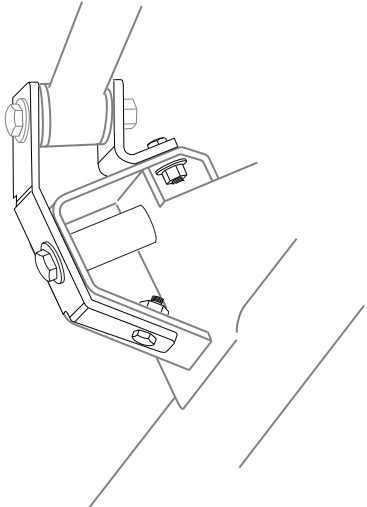

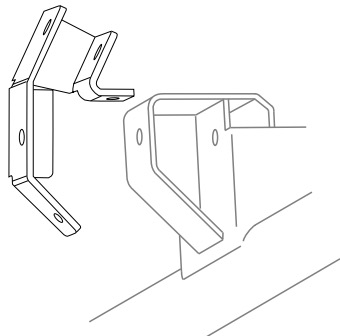

Position the Angled CV Bracket (A) over the OE track bar bracket on axle as indicated below.

HINT: Any dirt or debris should be cleaned from the OE axle bracket to ensure Angled CV Bracket (A) can be installed without obstruction.

Place the supplied gold colored 1.58” Spacer (B) into axle bracket “pocket”.

HINT: This spacer will be installed in the location vacated by the original track bar to prevent deformation of axle bracket.

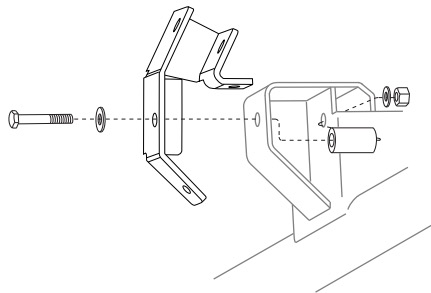

Mount Angled CV Bracket (A) to axle bracket by inserting the 1/2” x 3-1/4” Bolt (C) with 1/2” Flat Washer (D) through the original track bar mounting holes.

HINT: Bolt must also pass through gold colored spacer as indicated below.

Secure bolt with another 1/2” Flat Washer (D) and 1/2" Nylock Nut (E). Tighten 1/2” x 3-1/4” Bolt (C) to 65 ft-lbs. using a torque wrench.

Using the installed CV Bracket (A) as a template, drill two 5/16” holes in the OE axle bracket.

HINT: One hole is located on top, and the other is located on the angled surface below.

Insert the 5/16” x 1” Bolt (F) and Flat Washer (H) into the top hole, and secure with another 5/16” Flat Washer (H) and Nylock Nut (I).

Insert the 5/16” x 3/4" Bolt (G) and Flat Washer (H) into the bottom hole, and secure with another 5/16” Flat Washer (H) and Nylock Nut (I).

Tighten each 5/16” bolt to 35 ft-lbs. using a torque wrench.

3. RE-INSTALL REAR TRACK BAR

If installing an Adjustable Trackbar, it will be necessary to re-install the wheels and lower the vehicle first to determine the amount of adjustment required. Refer to the Adjustable Trackbar installation instructions for specific instructions.

If a non-adjustable or OE type track bar is being installed, proceed with the directions below.

If previously removed, re-install chassis end of track bar using the original mounting hardware.

Position axle end of track bar in Angled CV Bracket (A) and re-install original mounting hardware.

Using a torque wrench, tighten mounting hardware at both ends of track bar to 74 ft-lbs.

Re-install wheels and lower vehicle.

Maintenance

Check all torque specifications regularly.