How to Install Gibson Header - Chrome Plated on your Jeep Wrangler

Installation Time

3 hours

Tools Required

- 10, 12, 13, 15mm and 9/16” WRENCHES

- 10, 12, 13, 15mm and 9/16” SOCKETS

- 3”, 6”, AND 12” EXTENSIONS FOR SOCKETS

- SCREWDRIVERS AND/OR NUT DRIVERS

- GOOD RUST PENETRANT

INSTALLATION INSTRUCTIONS

NOTE: INSTALLATION OF THESE HEADERS REQUIRES AN ADEQUATE WORK SPACE, GENERAL MECHANIC'S TOOLS, GENERAL MECHANIC "KNOW-HOW" AND A REASONABLE DEGREE OF EXPERIENCE.

1. PLACE VEHICLE IN A LOCATION WHERE THE FLOOR IS SOLID AND FLAT, WITH ADEQUATE LIGHTING. DO NOT ATTEMPT TO WORK ON A HOT ENGINE. HEAT CAUSES METAL TO EXPAND AND MAKES REMOVAL OF FASTENERS DIFFICULT.

DISCONNECT THE BATTERY CABLES FROM THE BATTERY. RAISE THE FRONT OF THE VEHICLE TO OBTAIN ADEQUATE ACCESS TO THE BOTTOM EXHAUST MANIFOLD FLANGES. USE LARGE-BASED JACK STANDS TO SUPPORT THE VEHICLE. STARTING UNDERNEATH THE VEHICLE REMOVE FACTORY Y-PIPE ASSEMBLY FROM STOCK MANIFOLDS.

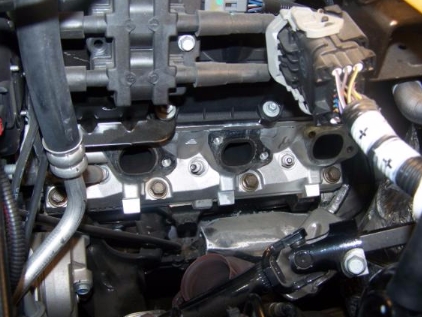

2. NOW STARTING UP TOP ON THE DRIVER SIDE, REMOVE STEERING SHAFT FOR REMOVAL OF FACTORY MANIFOLDS AND INSTALLATION OF HEADER. DISCONNECT ALL SPARK PLUG WIRES, REMOVE FACTORY HEAT SHIELDS AND MANIFOLD. MAKE SURE CYLINDER HEAD SURFACE IS CLEAN OF ANY DEBRIS BEFORE INSTALLATION OF HEADER.

3. NOW INSTALL GIBSON HEADER USING SUPPLIED GASKET RE-USING FACTORY BOLTS FOR INSTALL. TORQUE BOLTS FROM CENTER – OUT TO 30-35 FT-LBS. (NOTE: ON #4 CYLINDER AND SPARK PLUG WIRE, REMOVE STOCK SPARK PLUG BOOT USING A RAZOR BLADE MAKING SURE NOT TO CUT SPARK PLUG WIRE. USING WD-40 INSTALL NEW SUPPLIED 45O BOOT FOR HEAT CLEARANCE FROM HEADER.) ALSO INSTALL 2x6” SUPPLIED HEAT WRAP ON ALL SPARK PLUG WIRES FOR PROTECTION. AT THIS TIME USE SUPPLIED ZIP TIES TO KEEP SPARK PLUG WIRES FROM RESTING ON HEADER TUBES.

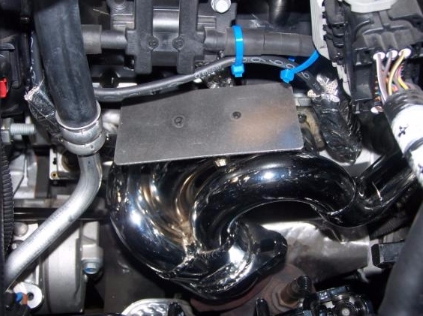

4. INSTALL THE HEAT SHIELD 5” X 8” ON THE PASSENGER SIDE # 1 CYLINDER TUBE TO PROTECT THE BATTERY BOX. THIS WILL PREVENT HEAT GOING TO COIL PACK ABOVE HEADER ASSEMBLY.

5. NOW RE-INSTALL STEERING SHAFT USING RED LOCKTITE BEFORE TORQUING FASTENER.

5. NOW ON PASSENGER SIDE REMOVE STOCK SHIELDS, SPARK PLUG WIRES, AND MANIFOLD. MAKE SURE TO CLEAN HEAD SURFACE OF ANY DEBRIS.

6. NOW INSTALL GIBSON HEADER WITH SUPPLIED GASKET RE-USING STOCK BOLTS TORQUING TO 30-35 FT-LBS FROM CENTER OUT. AFTER HEADER IS IN PLACE, USE SUPPLIED HEAT WRAP ON SPARK PLUG WIRES AND ZIP TIE TO KEEP AWAY FROM HEADER FOR HEAT PROTECTION. (NOTE: MAKE SURE ALL WIRES AND HOSES HAVE PROPER CLEARANCE FROM HEADER!)

7. AFTER HEADERS ARE IN PLACE. RE-INSTALL FACTORY Y-PIPE ASSEMBLY USING SUPPLIED BOLT KIT. NOW RE-CONNECT BATTERY. CHECK FOR ALL PROPER CLEARANCES THEN START VEHICLE AND THEN CHECK FOR ANY LEAKS. AFTER WARM-UP LET VEHICLE COOL DOWN AND RETORQUE ALL FASTENERS.

8. PERIODICALLY CHECK AND RETIGHTEN THE HEADER BOLTS.

NOTE: IT IS NOT UNUSUAL WHEN INSTALLING HEADERS TO GET A BURNING SMELL. THIS IS NORMAL AND IT WILL GO AWAY!