How to Install a Fabtech 4 in. Basic Lift Kit W/Shocks on your 1997-2006 Jeep Wrangler TJ

Installation Time

1 days

Tools Required

- FLOOR JACK & JACK STANDS

- ASSORTED METRIC AND S.A.E SOCKETS, & WRENCHES

- TORQUE WRENCH

- DRILL AND ASSORTED DRILL BITS

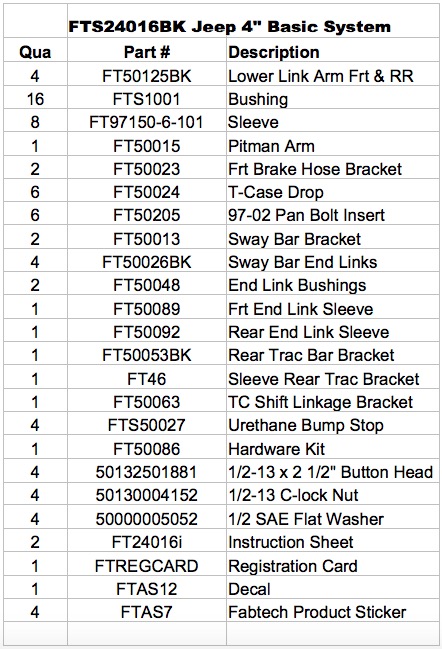

Parts List

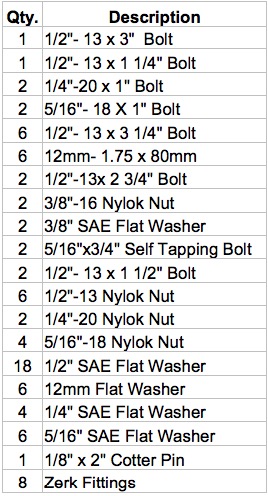

Hardware List

SOME 2003 & UP MODELS MAY REQUIRES FRONT DRIVE MODIFICATION, CHECK DRIVE LINE BEFORE DRIVING JEEP.

DO NOT ALTER THE FINISH OF THESE COMPONENTS, EXAMPLE- CHROMING, ZINC PLATING OR PAINTING. CHANGING THE FINISH CAN CAUSE STRUCTURAL FATIGUE OF COMPONENTS.

SUSPENSION SYSTEM MUST BE INSTALLED WITH FABTECH SHOCK ASBORBERS.

VEHICLES THAT WILL RECEIVE OVERSIZED TIRES SHOULD CHECK BALL JOINTS, TIE RODS ENDS AND IDLER ARM EVERY 2500-5000 MILES FOR WEAR AND REPLACE AS NEEDED.

THIS KIT IS DESIGNED TO BE INSTALLED ON A JEEP WITH STOCK AXLES & STOCK TRANSFER CASE & STOCK SUSPENSION.

NOT ALL JEEPS COME WITH FRONT ECCENTRIC CAMS FROM THE FACTORY,SOME JEEPS WILL REQUIRE MORE CASTER TO HELP WITH ALIGNMENT, CONTACT YOUR JEEP DEALER FOR ECCENTRICS IF NEEDED. READ ALL INSTRUCTIONS THOROUGHLY FROM START TO FINISH BEFORE BEGINNING INSTALLATION! IF THESE INSTRUCTIONS ARE NOT PROPERLY FOLLOWED, SEVERE FRAME, DRIVELINE AND / OR SUSPENSION DAMAGE MAY RESULT. NOTE- PRIOR TO THE INSTALLATION OF THIS SUSPENSION SYSTEM A FRONT END ALIGNMENT MUST BE PERFORMED AND RECORDED. DO NOT INSTALL THIS SYSTEM IF THE VEHICLE ALIGNMENT IS NOT WITHIN FACTORY SPECIFICATIONS. CHECK FOR FRAME AND SUSPENSION DAMAGE PRIOR TO INSTALLATION. THIS SUSPENSION SYSTEM DOES NOT REQUIRE WELDING FOR INSTALLATION. DO NOT WELD ANY OF THESE COMPONENTS.

CHECK ALL PARTS INCLUDED IN THIS KIT TO THE PARTS LIST ABOVE BEFORE BEGINNING INSTALLATION OF THE KIT. IF ANY PIECES ARE MISSING, CONTACT FABTECH AT 909-597-7800.

FRONT SUSPENSION INSTRUCTIONS:

1. Disconnect the negative terminal on the battery. With the Jeep on level ground set the emergency brake and block the rear tires. Jack up the front end of the truck and support the frame rails just behind the front bumper with jack stands. NEVER WORK UNDER AN UNSUPPORTED VEHICLE! Remove the front tires. Support the front axle with a floor jack just enough so that axle does not hang freely.

2. Working from both sides of the Jeep, remove the front lower track bar bolt and save. Pull track bar free from factory mount.

3. Remove the sway bar link ends from the sway bar and lower axle mount and discard.

4. On 2003 models equipped with automatic transmissions, you will need to remove the automatic transmission skid plate and discard.

5. Remove the front shocks and discard. Save factory lower shock hardware, discard upper hardware.

6. Remove the front drive shaft and save all hardware. On some 2003 & up models you will need to shorten the front driveline 1 ¾”, check drive shaft for proper clearance before driving. On 1997-2002 models the stock driveline can be reinstalled without modification.

7. Remove front coil springs and discard, save lower coil spring retainer (if equipped) and hardware. Remove factory upper bump stop and discard.

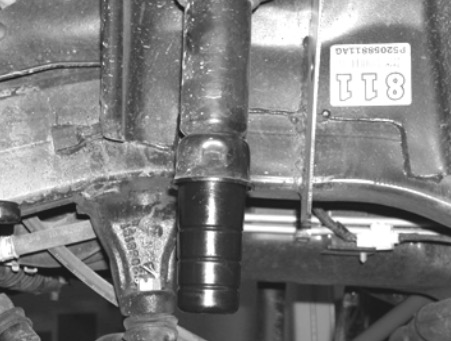

8. Support the front axle with a floor jack and remove both factory lower link arm and discard links and save the factory hardware. Locate the new Fabtech lower link arms FT50125BK. Install one of the supplied grease fitting into each end of the Fabtech Link arm. Press in two bushings and one sleeve into each end of the end link. Using factory hardware install the new link arm into factory frame mount, then attach to axle mount using the factory alignment cam bolts. Leave loose. NOTE: MAKE SURE THE GUSSETS ON BOTH ENDS OF THE LINK ARM ARE FACING DOWN. SEE PHOTO

9. Locate the factory brake line tab on the frame and remove bolt. Locate the new Fabtech brake line bracket FT50023 and attach it to the frame with the stock bolt. Now attach the stock brake line tab to the new Fabtech bracket with the supplied 5/16 x 1” bolt, nut, and washer. SEE PHOTO BELOW.

Rubicon models brake lines will remain in stock location.

10. Locate the new Fabtech bump stop FT50027. Install it into factory pocket by pushing the bump stop in until fully seated. SEE PHOTO

11. Locate the new Fabtech lift coil springs FT50004 and install into the truck. You will want to slide coil over the upper bump stop first then seat the coil in the lower pocket. If truck was equipped, reinstall lower coil spring retainer.

12. Working from both sides of the truck Torque the lower link arm bolts on the frame mounts to 130 ft lbs and to the axle mounts to 85 ft lbs.

13. Locate the new Fabtech front shocks FT7172 (not included in kit) and install using factory lower hardware and the supplied upper hardware from shock kit.

14. Locate the factory pitman arm, remove and discard, save the hardware. Locate the new Fabtech drop pitman arm FT50015. Install it back onto the truck in the same clock position as when it was removed, use the factory hardware and the supplied cotter pin to attach, torque to 185 ft lbs. SEE PHOTO BELOW.

15. Locate the factory mount hole for the track bar. Measure ¾” from the center of the hole toward the driver side. Mark the spot and drill a hole. Reattach factory trac bar to the new hole with the factory hardware torque to 55 ft. lbs. SEE PHOTO BELOW.

16. With a transmission jack support the transmission and transfer case, remove the factory transmission crossmember, discard the factory hardware.

17. Locate the factory transfer case shift linkage on the driver side of the transmission. Remove the two bolts securing the linkage to the body. (On some models you may need to remove the linkage pivot arm from the truck and bend the tab connecting the linkage pivot arm to the floor shifter to clearance the new linkage drop bracket bolts. It is recommend to install the linkage drop first to check for clearance, if clearance is needed than proceed in bending tab. See Photo In Next Column). Locate the new Fabtech linkage drop bracket FT50063. Using the supplied ¼ x 1” bolts, nuts, and washers attach the factory linkage to the lower two holes in the new linkage bracket. Using the factory hardware attach the new Fabtech bracket to the body. NOTE: WHEN INSTALLATION OF LIFT KIT IS COMPLETE YOU MAY NEED TO ADJUST LINKAGE ROD ON THE TRANSFER CASE

LINKAGE FOR PROPER SHIFTING. SEE PHOTOS BELOW

Linkage Pictured Bent Above

18. On manual transmission models you will need to remove the shifter arm from the center console of the truck and make a small bend in the shift arm as shown below. SEE PHOTOS BELOW.

Shifter Unbent

Shifter Bent

19. Locate the Fabtech transmission crossmember spacers FT50024 and (FT50205 Pan Bolt Taper Insert for 97-02 Models only). Using the correct supplied bolts and washers for your year Jeep, ½” x 3 1/4”(1997-2002) or 12mm-1.5 x 69.5mm (2003) reattach factory crossmember to the truck with the Fabtech spacer between the frame and the crossmember. Torque bolts to 85 ft lbs. On 97-02 models, place the Pan Bolt Taper Inset into the crossmember before the bolting the crossmember to the frame. SEE PHOTOS BELOW AND ON NEXT PAGE.

20. Reinstall the front driveline, using factory hardware. REMEMBER TO CHECK DRIVELINE AT RIDE HEIGHT FOR PROPER LENGTH.

21. Locate the supplied FT50026 sway bar end links. Press in one bushing and one sleeve from sleeve pack FT50089 into each end of the end link.

22. Locate FT50013 Sway Bar End Link upper bracket. Attach this bracket to the sway bar using the supplied 3/8” nylok nut and washer. Using the supplied ½ x 2 ½” button head bolts attach the sway bar end link to the truck as shown below. Torque to 45 ft. lbs SEE PHOTOS BELOW AND IN NEXT COLUMN.

Pictures show Optional Trac Bar Bracket

23. Install front tires and wheels. Torque lug nuts to wheel manufacturers specifications.

24. Steer the front wheels left to right fully and check the brake hose and ABS line if equipped for proper clearance from the tire and all other moving parts.

REAR SUSPENSION INSTRUCTIONS:

25. Jack up the rear end of the vehicle and support the frame rails just in front of the rear bumper with jack stands. NEVER WORK UNDER AN UNSUPPORTED VEHICLE! Remove the rear tires. Support the rear axle with a floor jack just enough so that axle does not hang freely

26. Working on both sides of the truck and supporting the rear differential with a jack remove and discard the rear shocks, save shock hardware. Use care not to over extend the brake hose.

27. Remove and discard the factory rear sway bar end links. Save hardware.

28. Locate the lower track bar mount on the axle. Disconnect the track bar from the axle and save hardware. Pull track bar free from the factory mount. Remove the factory plastic trim guard from the trac bar axle mount and discard.

29. Remove the coil springs and discard.

30. Remove the factory rubber bump stop and discard.

31. Locate the new Fabtech rear track bar bracket FT50053BK. Place the bracket on factory axle mount. With the supplied ½” x 3 ” bolt, nut, washers, and Fabtech sleeve FT46 attach the lower hole of the bracket to the factory hole in the axle bracket. (NOTE: THE SUPPLIED SLEEVE WILL BE PLACED INSIDE THE FACTORY TRAC BAR POCKET TO TAKE THE PLACE OF WHERE THE TRAC BAR WAS ORIGINALLY MOUNTED). Locate the hole in the Fabtech bracket on the outer side. Drill a ½” hole through the factory axle mount. Attach with the supplied ½” x 1¼” bolt, nut, and washers. Reattach the track bar to the new bracket with the factory hardware. Torque all trac bar bolts to 74 ft. lbs. SEE PHOTO BELOW.

32. Using a floor jack to support the axle, locate the factory lower link arms and remove, discard links and save the factory hardware.

33. Locate the new Fabtech lower link arms FT50125BK. Install one of the supplied grease fitting into each end of the new Fabtech link arm. Press in two bushings and one sleeve into each end of the end link. Using factory hardware install new Fabtech link arms into the factory frame mounts, then attach to axle mounts using factory hardware. Leave loose. NOTE: MAKE SURE THE GUSSETS ON BOTH ENDS OF THE LINK ARM ARE FACING DOWN. SEE PHOTO IN NEXT COLUMN.

34. Locate the new Fabtech bump stop FT50027. Install into factory pocket by pushing the bump stop in until fully seated.

35. Locate the new Fabtech lift coils FT50005. Install new lift coils into truck.

36. Locate the new Fabtech shocks FTS7173 (not included in kit). Install on truck using factory hardware.

37. Torque the lower link arms to 130 ft. lbs

38. Locate the supplied FT50026 rear sway bar end links. Press in one bushing and one sleeve into each end of the end link. Install the end links onto truck using stock hardware. Torque to 45 ft lbs.

39. Install rear tires and wheels and torque lug nuts to wheel manufacturers specifications. Turn front tires left to right and check for appropriate tire clearance.

40. Using a grease gun, grease all grease fittings in the new Fabtech Link Arms.

41. Recheck all nuts and bolts for proper torque tightness before driving. Drive the truck for 50 miles and have it aligned to factory specifications. Make sure to check the front driveline for proper clearance at ride height. Re-adjust headlights.

RETORQUE ALL NUTS, BOLTS AND LUGS AFTER 50 MILES AND PERIODICALLY THEREAFTER.

For technical assistance call: 909-597-7800

Product Warranty and Warnings

Fabtech provides a Limited Lifetime Warranty to the original retail purchaser who owns the vehicle, on which the product was originally installed, for defects in workmanship and materials.

The Limited Lifetime Warranty excludes the following Fabtech items; bushings, bump stops, ball joints, tie rod ends, limiting straps, cross shafts, heim joints. These parts are subject to wear and are not considered defective when worn. They are warranted for 60 days from the date of purchase for defects in workmanship.

Take apart shocks are considered a serviceable shock with a one year warranty on leakage only. Service seal kits are available separately for future maintenance. All other shocks are covered under our Limited Lifetime Warranty.

Fabtech does not warrant any product for finish, alterations, modifications and/or installation contrary to Fabtech’s instructions. Alterations to the finish of the parts including but not limited to painting, powdercoating, plating and/or welding will void all warranties. Some finish damage may occur to parts during shipping which is considered normal and is not covered under warranty.

Fabtech products are not designed nor intended to be installed on vehicles used in race applications or for racing purposes or for similar activities. (A “RACE” is defined as any contest between two or more vehicles, or any contest of one or more vehicle against the clock, whether or not such contest is for a prize). This warranty does not include coverage for police or taxi vehicles, race vehicles, or vehicles used for government or commercial purposes. Also excluded from this warranty are sales outside of the United States of America.

Installation of most suspension products will raise the center of gravity of the vehicle and will cause the vehicle to handle differently than stock. It may increase the vehicle’s susceptibility to a rollover, on road and off road, at all speeds. Extreme care should be taken to operate the vehicle safely at all times to prevent rollover or loss of control resulting in serious injury or death. Fabtech front end Desert Guards may impair the deployment or operation of vehicles equipped with supplemental restraining systems/air bag systems and should not be installed if the vehicle is equipped as so.

Fabtech makes every effort to ensure suspension product compatibility with all vehicles listed in the catalog, but due to unknown auto manufacturers production changes and/or inconstancies by the auto manufacturer, Fabtech cannot be responsible for 100% compatibility, including the fitment of tire and wheel sizes listed. The Tire and Wheel sizes listed in Fabtech’s catalog are only a guideline for street driving with noted fender trimming. Fabtech is not responsible for damages to the vehicle’s body or tires.

Fabtech’s obligation under this warranty is limited to the repair or replacement, at Fabtech option, of the defective product only. All costs of removal, installation or re-installation, freight charges, incidental or consequential damages are expressly excluded from this warranty. Fabtech is not responsible for damages and/or warranty of other vehicle parts related or non related to the installed Fabtech product. This warranty is expressly in lieu of all other warranties expressed or implied. This warranty shall not apply to any product that has been subject to accident, negligence, alteration, abuse or misuse as determined by Fabtech.

Fabtech suspension components must be installed as a complete system including shocks as shown in our current catalog. All warranties will become void if Fabtech parts are combined and/or substituted with other aftermarket suspension products. Combination and/or substitution of other aftermarket suspension parts may cause premature wear and/or product failure resulting in an accident causing injury or death. Fabtech does not warrant products not manufactured by Fabtech.

Installation of Fabtech product may void the vehicles factory warranty; it is the consumer’s responsibility to check with their local vehicle’s dealer for warranty disposition before the installation of the product.

It is the responsibility of the distributor and/or the retailer to review all warranties and warnings of Fabtech products with the consumer prior to purchase.

Fabtech reserves the right to supercede, discontinue, change the design, finish, part number and, or application of parts when deemed necessary without written notice. Fabtech is not responsible for misprints or typographical errors within the catalog or price sheet.