How to Install a Wild Boar Fastback Targa Top on your 2007-2014 Wrangler JK 4 Door

Step1: Remove your softop and all hardware if you have not done so. If your Jeep has the molded rubber seal on top of the belt rail located right behind each door; remove it as well. (Fig.1)

Step 2:With the help of friends, place your Fastback Top on your Jeep with the rear door of your Jeep open.

Step 3: Align your top so that it sits on top of the factory rubber. (Fig.2)

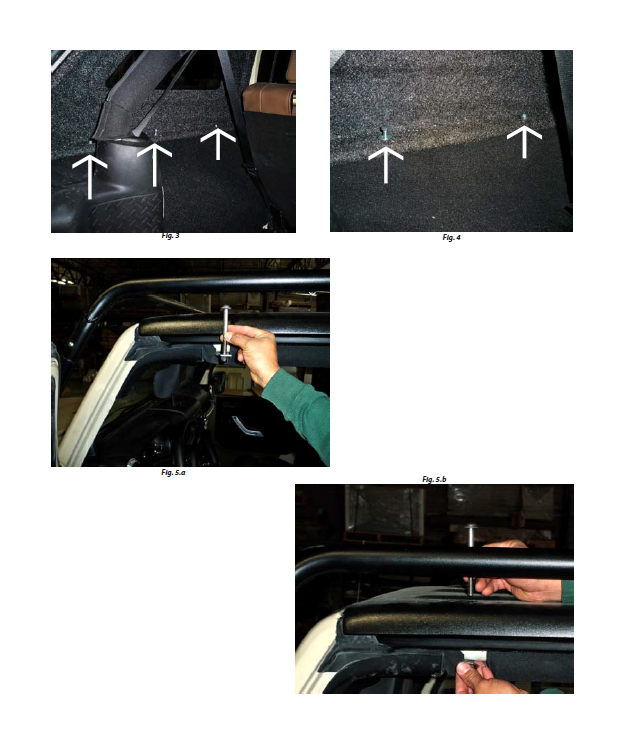

Step 3: Once aligned properly, begin to install the six bolts around the rear rail. (Fig.3)

Step 4: Using a 1/2” wrench or socket (13mm) tighten down your top. Close your rear door and make sure everything is align properly. (Fig.4)

Step 5: Using the two (2) long bolts with acorn nuts and washers that were provided. Drive them in through the top front corners through the rollbar. Use these to tighten down the front corners to your Jeep. (Fig. 5.a)

Step 6: Using a 7/32” allen wrench and a 5/8” (16mm) wrench tighten down the bolt so that the top ends up even and flush with the Jeep. (Fig. 5.b)

Note: You may need to use all or any washers at all to tighten down the bolt.

The bolt and acorn nut are stainless steel; self welding may occur.