How to Install a Daystar Hood Cowl on your 2007-2017 Jeep Wrangler JK

Installation Time

4 hours

Tools Required

- Drill

- 1/6” Drill Bit

- 5/16” Drill Bit

- 3/4” Hole Saw

- 1-1/4” Hole Saw

- Angle Grinder

- Sheet Metal Nibbler / Body Saw

- 1/4” Drive

- 11/32” Deep Well Socket

- 10mm Socket

- Blue Painters Tape

- Center Punch

- Razor or X-Acto Knife

- Marker or Paint Pen

- Scissors

- Touchup Paint

- Fir Tree / Christmas Removal Tool

- Telescoping Magnet

- 50/50 Solution of Rubbing Alcohol & Water

www.Daystarweb.com

Tech Support Contact Info:

[email protected]

Phone: 623.907.0081

Fax: 623.907.0088

841 South 71st Avenue

Phoenix, AZ 85043

Instruction Sheet: P21363

2014 Daystar Products International Inc.

Revision: 1

Revision Date: 06/30/14

Revised by: PH

Introduction

Daystar is your number one source for Made In The USA quality vehicle accessories, now backed with our exclusive Go Everywhere © Lifetime Limited Warranty (see terms at Daystarweb.com). To ensure your safety and proper installation of this product, take a moment to read all instructions and product safety information before trying to install your Daystar® product. If you have technical questions after reading these instructions, we are here to help: contact us at 800-595-7659

Product Safety Information

Throughout these instructions important safety information is generally preceded by one of three signal words indicating the relative risk of injury. The signal words mean:

! WARNING A hazardous situation which, if not avoided, could result in death or serious injury. You can be seriously injured or killed if you don’t follow instructions.

! CAUTION A hazardous situation which, if not avoided, could result in minor or moderate injury. You can be moderately hurt and also may suffer property damage if you don’t follow instructions.

NOTICE Careful attention is required to this instruction or operation, but does not generally relate to personal injury. Damage to your product or other property may result if you don’t follow instructions.

!WARNING

Familiarize yourself with all vehicle manufacturer and Daystar warnings, instructions, and limited warranties before driving your modified suspension vehicle. Also, be aware that many states / countries have laws governing on-road vehicle heights and modifications. You are responsible for ensuring the safety and legality of your vehicle. A summary of current state vehicle laws is available at www.sema.org.

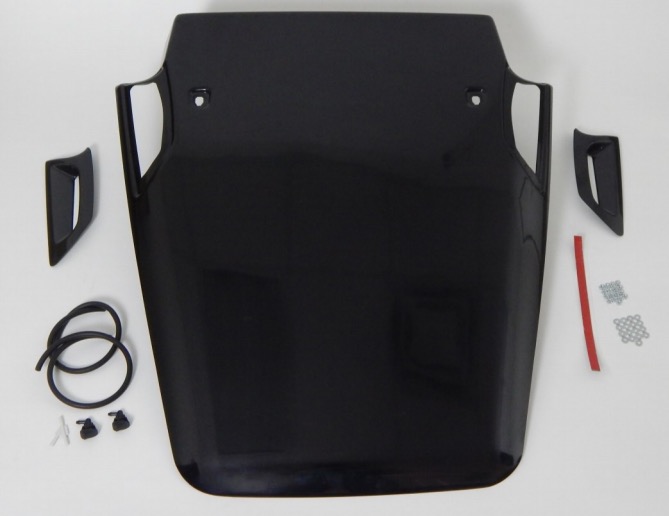

Bill of Materials

| Quantity | Part Number | Description |

|---|---|---|

| 1 | M56137 | JK Cowl |

| 1 | M56141 | JK Cowl Vent - Left |

| 1 | M56142 | JK Cowl Vent -Right |

| 1 | M21344-BK | Poly Vent Ring |

| 1 | P21363 | Instructions |

| 1 | P21364 | Template |

| 17 | S21169 | #8 Flat Washer |

| 17 | S21396 | 8-32 Hex nut |

| 1 | P21365 | Blue Loctite |

| 2 | P21404 | Washer Nozzle |

| 1 | P21405 | 3/16” Y-Tee |

| 2 | P21409 | 18” Section of 5/32” Rubber Hose |

| 1 | P21413 | 10” Section of Automotive Adhesive Tape |

Installation Instructions

!Warning: Always work with appropriate personal safety gear including safety glasses, gloves and hearing protection if using air powered tools.

Begin by inspecting the components & hardware for damage. Then compare components & hardware to the bill of materials for completeness. If anything is missing/ damaged, do not proceed with the installation. Please, call Daystar Products (800-595-7659) and we will send you the missing of damaged components free of charge.

1. Raise hood and remove the hood insulation blanket.

Tools: Fir tree removal tool.

2. Remove footman loop (Figure 1).

Tools: 1/4” drive & 10mm socket.

3. Remove windshield bumpers (Figure 2).

Note: 2007-2010 pull right out, 2011 & later require depressing two tabs located on the bottom side of the hood.

4. Remove the washer nozzle (2007-2011) or nozzles (2012– Later).

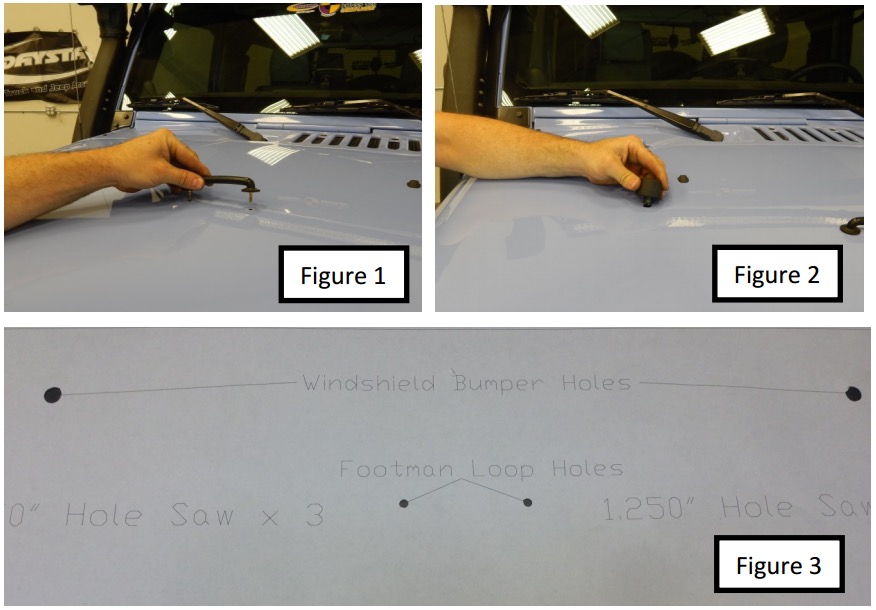

5. Lay the template on a flat surface and cut out the footman loop holes and the windshield bumper holes (Figure: 3).

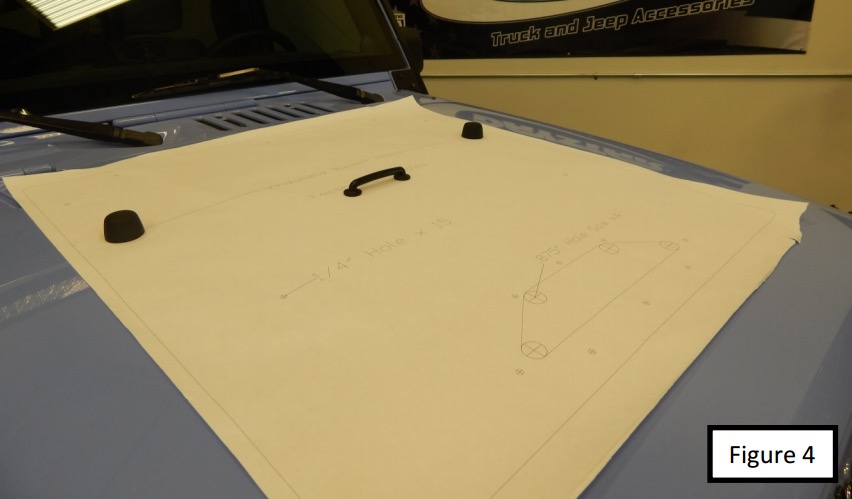

6. Place template onto the hood.

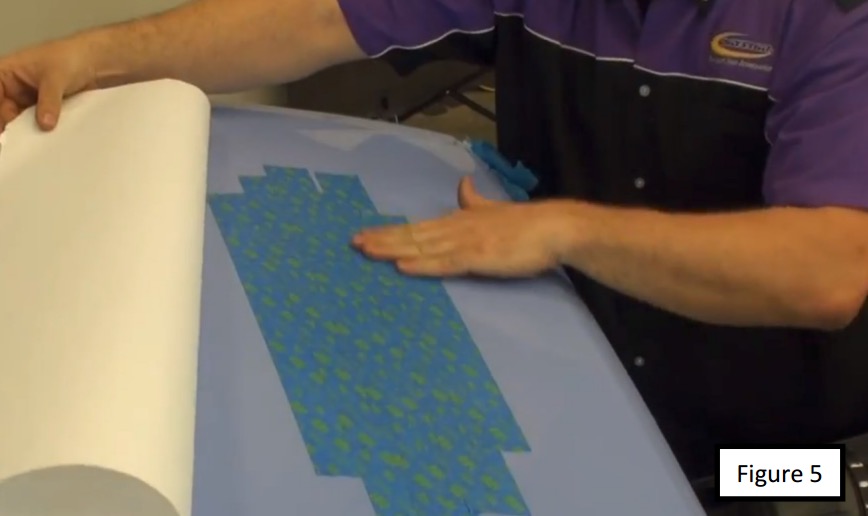

7. Using the hood bumpers and footman loop locate the template on the hood (Figure 5 next page).

8. Once the template is placed on the hood, make sure it is square.

9. Tape the top edge of the template, so that it will not move.

10. Place the painters tape under the areas that are to be drilled and cut out. This step will protect the paint during the installation procedure (Figure 5)

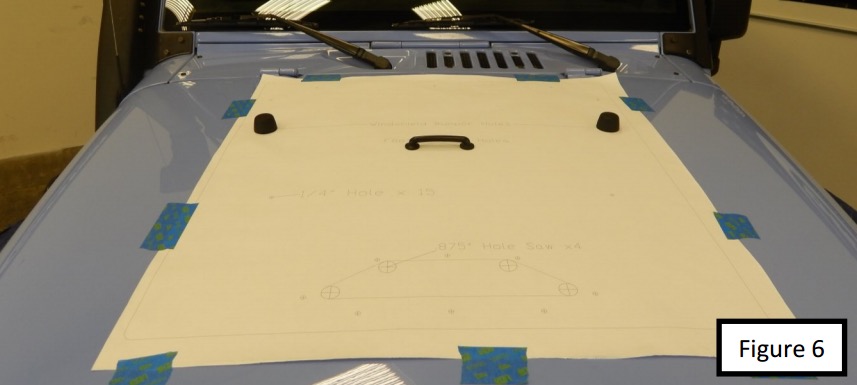

11. Lay the template out and tape it down to the hood. Make sure that the template is laying as flat as possible without any wrinkles (Figure 6).

12. Open the hood and place a blanket over the engine bay to protect it from metal shavings and chips.

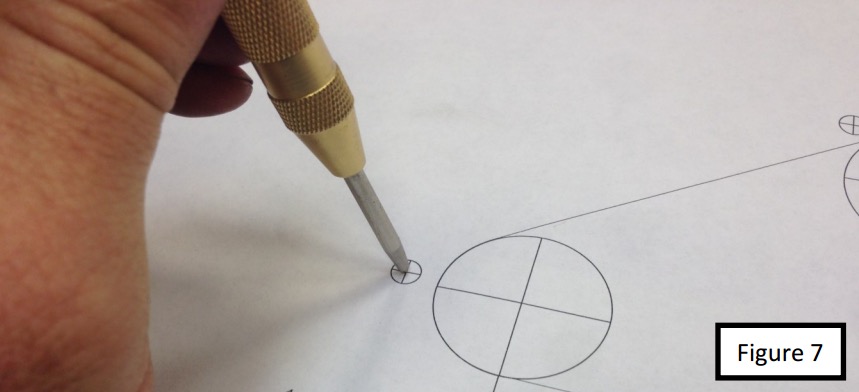

13. Center punch all of the holes to be drilled (Figure 7). Note: Be sure to support the hood from underneath, so the hood’s sheet metal does not deform.

14. Use the 1/16” drill bit to create a pilot hole for all of the center punched holes. Make sure to drill through both layers in the center rear hole and the two holes directly in front of the hinges (Figure 8).

15. With a 5/16” drill bit, open up all the pilot holes drilled except for the four 1-1/4” holes inside of the vent cut out (Figure 9).

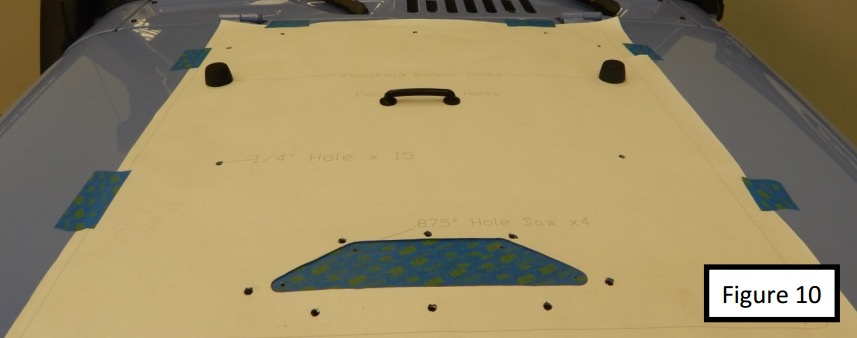

16. Using a razor or X-Acto knife, cut the vent profile out of the template (Figure 10).

17. Take a marker and trace the vent profile onto the hood. Figure: 11

18. Use the 1-1/4” hole saw to cut out the four holes on the interior of the vent cut out (Figure 12).

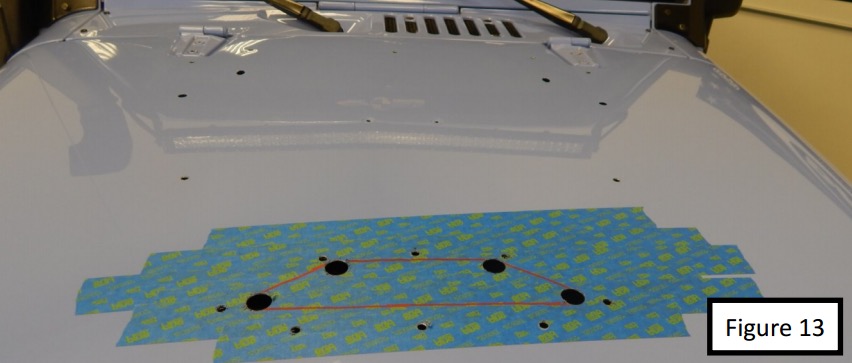

19. Remove the template and blow the metal shavings off of the hood (Figure 13).

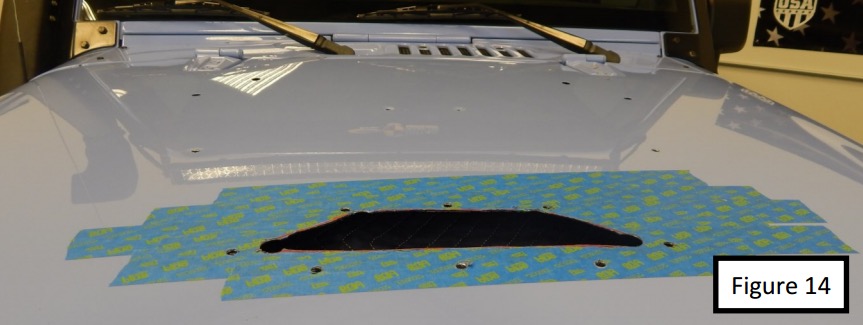

20. Using a sheet metal nibbler or body saw, cut out the interior portion of the vent (Figure 14).

21. With an angle grinder open up the vent hole until it matches the line traced from the template (Figure 15).

22. Once the vent hole is trimmed to size, remove the tape and clean off any debris.

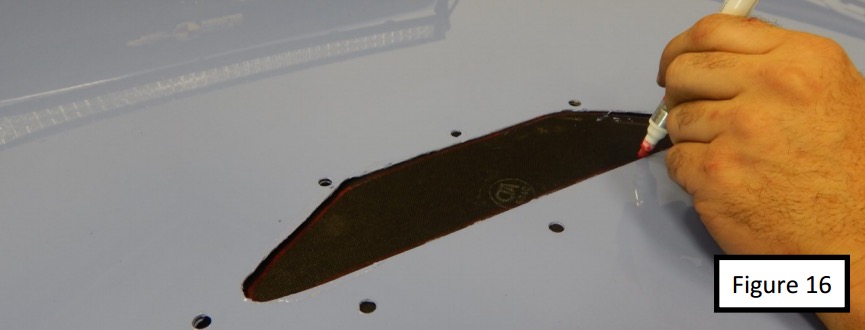

23. Reinstall the hood heat blanket, only using the hood tabs, and mark the vent cut out (Figure 16).

24. Remove the hood blanket and place it on a hard, level surface.

25. With the poly ring and marker, trace the outside perimeter of the ring onto the hood blanket. Use the line traced in step 23 as a guide (Figure: 17).

26. Measure in 1/2” from the outside line that was traced on to the hood heat blanket and place a mark. Repeat this procedure around the perimeter of the vent. (Figure 18).

27. Using the marks placed 1/2” inside the outer line, cut out the center portion of the heat blanket (Figure19)

28. Set the hood heat blanket to the side and shift to the underside of the hood.

29. Prop open the hood.

30. Locate the three (3) holes in the rear portion of the hood that need to be drilled out.

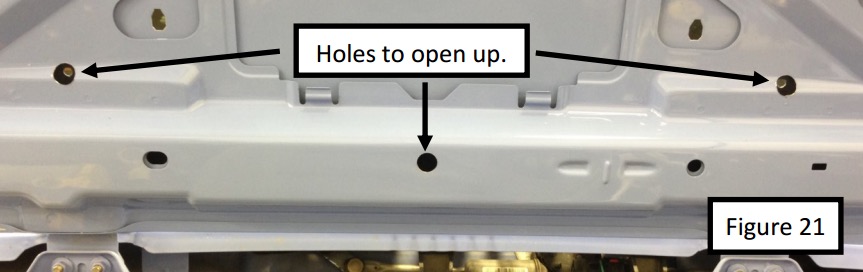

31. With a 3/4” hole saw, open the three holes in the rear of the hood. (Figure 20).

32. Once completed, the underside of the hood will look like Figure 21.

33. Use the touch up paint to cover any sheet metal that was exposed during the drilling and cutting steps.

34. You will now move on to the preparation of the Daystar JK Hood Cowl. Note: The Hood Cowl and Side scoops must be painted to protect them from UV damage.

35. Place the hood cowl on a smooth surface.

36. Attach a section of rubber tubing, about 18” long, to each washer nozzle.

37. Place a nozzle into each of the holes in the cowl. Make sure the nozzles are securely fastened. You should hear both of the tabs click into place (Figure 22). Note: Jeeps equipped with a single washer nozzle from the factory, will require the Y-tee connection to be made between the hood and the cowl. So only one hose will route through the hood.

38. Cut the adhesive tape into 10 - 1” sections ( /- .125”), then apply to the back of the hood cowl vents. Pre-fit the cowl vent to check placement, then remove the adhesive backing (Figure 23).

39. Before placing the vent onto the cowl make sure the surface is clean. A 50-50 mix of water and rubbing alcohol will do the trick. When placing the vent, it is best to hoover the vent over the cowl until you are satisfied with the position, then press it into the cowl (Figure 24)

40. Repeat step 39 on the other side.

41. Put a dab of blue thread locker onto each of the cowl’s studs.

42. Place the cowl onto the hood. Feed the washer lines through the old nozzle hole(s) in the hood.

43. Use a washer and 8-32” nut on each of the studs, except for the eight (8) that surround the vent cut out. For the three (3) rear most studs, place a bit of tape around the nut to hold it into the socket. Use a magnet to place the washers on each stud.

44. Once the nine (9) studs have nuts and washers installed tighten them down to 15 in.lbs.

45. Reinstall the hood blanket.

46. Place the polyurethane trim ring over the eight (8) mounting studs.

47. Tighten the nuts until the polyurethane starts to bulge (Figure 25).

45. Using the Y-Tee provided hook up the two (2) nozzle lines to the factory washer fluid line (Figure 26). Note: Jeeps equipped with a single washer nozzle from the factory, will require the Y-tee connection to be made between the hood and the cowl. So only one hose will come through the hood.

49. Congratulations, you have completed the install of the Daystar JK hood cowl. Take a step back and admire your work!

Daystar® Lifetime GoEverywhere Limited Warranty

Your Daystar® Comfort Ride™ or Budget Boost™ leveling kit is covered by the following Go Everywhere Lifetime Limited Warranty provided exclusively by Daystar Products International, Inc., 841 South 71st Ave., Phoenix, AZ 85043 (“Daystar”).

What is Covered? Real Life Use, Off Road & On: Subject to the terms, exclusions and limitations herein, Daystar® warrants to the initial retail purchaser that your Comfort Ride™ or Budget Boost™ leveling kit shall be free of defects in material and workmanship for so long as it is properly installed on a single vehicle owned by the initial retail Daystar® purchaser.

What is Not Covered? Your Vehicle & Parts That Are Not Daystar’s GoEverywhere: Your Daystar Limited Warranty does not cover: (a) damage to your vehicle, vehicle systems (ex. electronic stability control) other products, components or property not manufactured by Daystar to our exclusive GoEverywhere standards, (b) customer choice of vehicle configuration/tire and wheel combinations contrary to Daystar® recommendations, warnings or applicable laws, (c) Acts of God, weather, corrosion, accidents, theft, vandalism, negligent misuse or intentional damage, other exclusions under your OEM Limited Warranty.

Remedy Limited to Repair/Replacement. Get back on your favorite trail fast. The exclusive remedy provided hereunder shall, upon Daystar’s inspection and option, be either repair or replacement of the Comfort Ride™ or Budget Boost™ leveling kit or parts covered under this Limited Warranty. Call us and we will get you back wheelin’ (623/907-0081). All labor, removal, shipping and installation costs are the customer’s responsibility.

Other Exclusions –Limitation of Damages - Your Rights Under State Law. Stuff Lawyers Say. At Daystar® we aren’t big fans of lawyers, even ours. Still, he says our Limited Warranty has to include this stuff. In consideration of the purchase price paid, neither Daystar® nor any independent Daystar® distributor or repair person are responsible for any time loss, loss of vehicle use, rental costs, transportation, labor or for any incidental, consequential, punitive or other damages you may have or incur in connection with any part or product purchased. No Daystar® employee or independent distributor is authorized to make any statement or representation altering the terms of Daystar’s GoEverywhere Lifetime Limited Warranty. Your exclusive remedy hereunder for covered parts is repair/replacement as described above. This Limited Warranty gives you specific rights. You may also have other rights that vary from state to state. For example, some states do not allow limitations of how long an implied warranty lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the limitations and exclusions herein may not apply to you.

All other warranties are hereby disclaimed, except to the extent prohibited by applicable law in which case any implied warranty of merchantability, fitness for a particular purpose or other implied warranty are limited to a period of four (4) years from date of initial retail purchase. Daystar® reserves the rights to: (a.) require invoice or other proof of purchase; (b.) make future revisions to these products and Limited Warranty without prior notice or obligation to upgrade your Daystar® product.

© Daystar Products International, Inc., 9.15.13. All rights reserved.