Last Day! Guaranteed Free Delivery 12/24. Order by 3pm EST available on most items - Details

How to Install Rugged Ridge 2 In. Lift Kit w/o Shocks on your 1987-1995 Wrangler

Shop Parts in this Guide

Congratulations on your purchase of a Rugged Ridge™ suspension kit. To fully enjoy and understand this product we ask that you take a few moments to read through these instructions. Before beginning the installation, read these instructions and the enclosed driver’s “WARNING NOTICE” thoroughly and completely. Also affix the “WARNING” decal in passenger compartment in clear view of all occupants. If any of these items are missing from this instruction packet, do not proceed with installation, but call Omix-Ada to obtain needed items. If you have any questions or reservations about installing this lift kit, call Omix-Ada at 770-614-6101 for Technical Assistance or Customer Service departments.

A Few Words About Safety:

Your safety and the safety of other motorists is very important. As the owner of a modified suspension vehicle you are the person choosing the combination of suspension, wheels, tires and drive train that best fit your intended use. Likewise, you are the person responsible for the safety and legality of the vehicle you modify. In modifying your vehicle’s suspension, balance your off-road capabilities against how the vehicle may actually be used off-road and on-road.

It is not practical or possible to warn about all hazards associated with modifying your suspension for improved off road capabilities. To help you make informed decisions about safety, we have provided certain information in the form of “Notices” and “Warnings”. This information alerts you to potential hazards that could hurt you or others.

Notice: This is a caution against anything which may cause damage to the vehicle or its equipment if the caution is ignored. The Notice includes information about how you can avoid or reduce those risks. Warning: This is a signal telling you that you CAN be KILLED or SERIOUSLY HURT if you don’t follow the

Warning. The Warning includes information about what you must or must not do in order to reduce the risk of injury to yourself and others.

The following Warning label is included with your Rugged Ridge™ suspension kit and should be placed on the vehicle visor or other conspicuous location after installation:

Pre-Installation Notes:

Notice: This kit should only be installed by a professional mechanic or individual with significant automotive experience.

• Refer to parts list and inventory your kit to insure all parts and hardware pieces are available before beginning installation. Contact your independent dealer immediately if parts are missing.

• Installed lift will vary depending on vehicle options and configuration. As a reference and important guide should technical assistance be required, establish base ride-height measurements before beginning installation. Park vehicle on hard, level surface. Carefully measure the four corners of the vehicle (front and rear –both sides) from the ground up to the center of the fender opening above the axle. Record below and save.

Driver Side Front: Passenger Side Front:

Driver Side Rear: Passenger Side Rear:

FRONT:

2. Open the hardware bag and apply a thin coat of lithium-based grease around the polyurethane bushings and insert into each eye of the new front springs then apply a thin coat on the outside of bushings. Insert the metal sleeves into the springs eyes.

3. Raise front of vehicle and support securely with jack stands under the frame behind front springs and block the rear wheels. Remove the tires, shocks, u-bolts (Caution: once the u-bolts are removed, the front axle will be free to move, so support securely on a floor jack). If a drop pitman arm was purchased (needed with 4" lifts, disconnect the tie rod from the original pitman arm, and install new arm (refer to instructions included with drop pitman arm).

4. Unbolt each end of the original front leaf springs and remove both springs from vehicle. If new shackle bushings were purchased, grease and install them at this time. Install the new springs with small eye toward the front bumper . (NOTE: It is important to NOT tighten the spring and shackle bolts at this time. If springs are tightened, with no load being applied on the springs, a false lift and stiff ride will result. These bolts will be tightened later once the vehicle is on the ground.)

5. While still supporting the front axle with the floor jack, lower axle down to the leaf springs. Be certain the tie bolt heads align and fit into the holes in the axle housing. Install the new u-bolts included and tighten them to 90 ft.lbs. Install tires and lower vehicle to the ground.

2-2.5" Lifts, skip step 6.

6. On 4" kits, a front track bar (pan hard rod) relocation bracket is required. This bracket is packaged separately with its own metric hardware (top of bracket is wide end with slotted hole, and offset should bend toward the front bumper over the original mounting tab). To install bracket, unbolt the factory track bar from the original bracket on axle (save the original nut to re-use). Place the bottom of new bracket just behind the original bracket on axle with a washer between the brackets, then insert the shorter metric bolt from the front going through the original bracket, then the washer, and next through the new bracket. Now install the new nut and tighten. Hook up track bar by first putting a washer on the new longer metric bolt and insert bolt though track bar (from the front), then through the slotted hole on new bracket. Tighten using the original nut.

NOTE: Be certain vehicle is on the ground and that vehicle weight is on the springs.

7. Tighten the track bar (pan hard rod) bolts (on 4" kits, this was done in step #6), and also tighten the sway bar bolts. If a polyurethane sway bar bushing kit was purchased, install it at this time.

REAR INSTALLATION:

8. Raise rear, support securely with jack stands and block the front wheels. Remove the tires, shocks and u-bolts. (Caution: the rear axle will now be free to move, so support securely on floor jack.)

9. Loosen the track bar bolt connecting the bar to axle housing and on 4" lifts, remove track bar from axle mount because because a relocation bracket will be installed in step 13).

10. Apply a thin coat of grease to the polyurethane bushings and insert into each eye of new rear springs. Now apply a thin coat of grease on outside of polyurethane bushings. Insert sleeves into spring eyes.

11. Notice each end of the factory springs (small eye-towards the rear bumper end and large eyetowards front) to see which way to install new springs. With a floor jack supporting the rear axle, unbolt each end of rear leaf springs and remove from both sides. These springs have a degree shim attached, spring must be installed with thick end of shim towards front bumper. Install spring eye bolts. (NOTE: Do NOT tighten spring eye bolts at this time.)

12. Using the floor jack, lower the rear axle down to leaf springs. Be sure tie bolts align and fit into the tie bolt holes in the axle housing. (NOTE: If new shackle bushings were purchased, grease and install them in the frame at this time.) Install and tighten new u-bolts, shocks and tires then lower vehicle to ground. Tighten spring eye bolts at this time.

2-2.5" Lifts, skip to step 14.

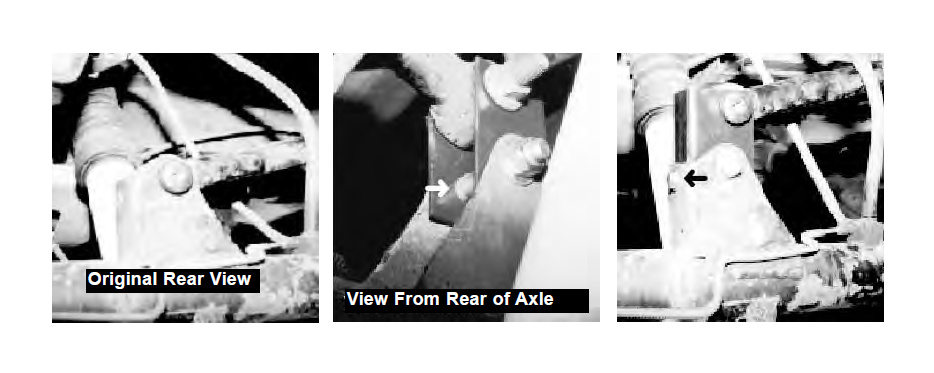

13. For 4" Lifts, place new rear track bar extension bracket into the stock bracket (on axle housing), with the slotted holes toward the top. Place the 1/2" x 1 1/2" spacer tube inside bracket (to prevent crushing, see white arrow) and install the 1/2" x 3" bolt and washer through original and new bracket and tighten securely with 1/2" lock nut. Insert track bar into new bracket, and install using original bolt and nut (do NOT tighten yet). Drill a 3/8" hole and install the new 3/8" x 1" bolt (see black arrow), washer and nut through side of new and original track bar bracket. Tighten all the track bar bolts and nuts at this time.

14. Check Brake Line Length, if they seem too short, longer stainless steel DOT Approved lines are available from Rugged Ridge. A driveline vibration may occur. If so, a transfer case lowering kit from Rugged Ridge should be installed.

NOTE: After driving the first 50 miles, re-torque ALL nuts, bolts and ESPECIALLY U-BOLTS, torque again for another 100 miles and then check periodically thereafter.

TROUBLE SHOOTING

Upon completion of installing the entire lift (front and rear) if the vehicle appears to sit un-level go to step 1 and record the AFTER measurements to verify the amount of lift obtained at each point. If the vehicle does sit un-level and it did not sit un-level in step 1, the following can be checked:

1. Be sure all of the polyurethane bushings were greased well so that they will not restrict the spring’s movement.

2. Check the condition of the shackle bushings in the frame (if not replaced with new ones) to be sure they are not worn, and if so, replace them with new polyurethane bushings.

3. Check the body bushings between the frame and the body to be sure they are not showing wear. If so, Omix-Ada offers replacement polyurethane kits.

4. In order to be sure that the bushings are not restricting the spring from being at the correct ride height, loosen (do not remove) the spring eye bolts. Then stand on the bumpers and bounce the vehicle up and down vigorously to free up the bushings and then retighten spring eye bolts.

Post Installation Checks/Alignment:

• After installation is complete, double check that all nuts and bolts are tight. (Do not retighten nuts and bolts where Loctite was used.) Check to ensure there is adequate clearance between all rotating, mobile and fixed members.

• Rotate driveshafts and check for interference at differential yoke and cardan joint. If necessary, lightly dress casting(s) and/or U-joint tabs in order to eliminate binding.

• Check clearance between inner side wall of tires and links. It may be necessary to adjust steering stops.

Notice: Adjust drag link so that steering wheel remains centered and wheel sweep from side to side remains equal. Failure to do so may cause computer errors, odd handling characteristics and poor performance. Have a qualified alignment center check and realign to factory specifications.

Notice: With vehicle securely elevated, carefully inspect and adjust to assure adequate clearance between tires (inner side wall), body and suspension components throughout range of steering and suspension travel. Additionally, carefully inspect and adjust to maintain clearance between suspension components, wiring harnesses, exhaust, brake and fuel lines, fuel tank, floorboards and body panels. Complete by properly torquing all fasteners.

Notice: With vehicle now on floor, again check clearances, cycle steering lock to lock and test proper brake operation. Raised vehicle height requires realigning headlights. Consult your state’s lighting regulations. Wheels must be realigned by qualified service center to factory specifications.

Notice: Re-torque fasteners after 500 miles. Thereafter, regularly inspect and re-torque as needed. Follow vehicle manufacturer’s recommended maintenance procedures and routinely inspect your vehicle components for unusual wear or off-road damage.

Warning: Avoid compromising vehicle handling and safety (including roll over risk) by NOT adding, combining or fabricating additional lift devices (ex. body lifts) with this product. Also be aware that most states have restrictions on height modifications for vehicles used on-road. Consult your vehicle owners manual, the instructions and warnings accompanying this product and state law before undertaking these modifications or using your modified suspension vehicle on-road. A summary of current regulations affecting modified suspension vehicles is available from www.SEMA.org.