2 Days Left! Guaranteed Free Delivery 12/24. Order by 3pm EST available on most items - Details

How to Install Poison Spyder Front Vented Inner Fenders - SpyderShell Armor Coat on your Wrangler

Installation Time

1 hours

Tools Required

- Mechanic's tool set

- Drill motor with #2 Phillips driver bit

- 3/8", 5/16" & 17/32" drill bits

- 3/4" hole saw, step-drill or knock-out punch

- Professional nut-sert installation tool (optional)

Shop Parts in this Guide

APPLICATIONS

These installation instructions apply to the following Poison Spyder products:

17-02-080-V JK Front Inner Fender Kit - Vented

17-02-080-VP I JK Front Inner Fender Kit - Vented - Block

PARTS LIST

Please check your packages immediately upon arrival to ensure that everything listed is included, and to check for damage during shipping. If anything is missing or damaged, call Poison Spyder at (951) 849-5911 as soon as possible. The ID numbers for each item correspond to the diagram on the following page.

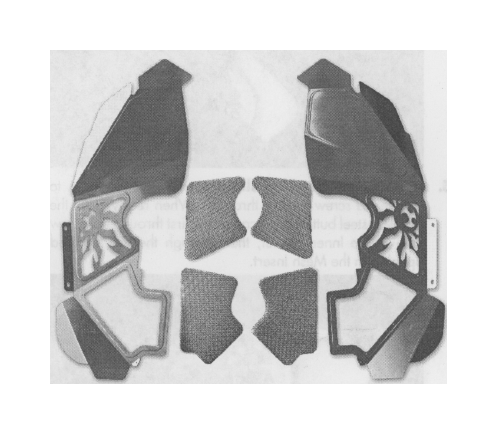

(1) JK Front Inner Fender - Vented - Left PN: 17-02-080-L-V

(1) JK Front Inner Fender - Vented - Right PN: 17-02-080-R-V

(2) JK Front Inner Fender -Vented - Mesh Insert Front PN: 17-02-080-01-MESH

(2) JK Front Inner Fender -Vented - Mesh Insert Rear PN: 17-02-080-02-MESH

(1) JK Front Inner Fender - Vented - Hardware Kit PN: HWKIT-17-02-080-V includes:

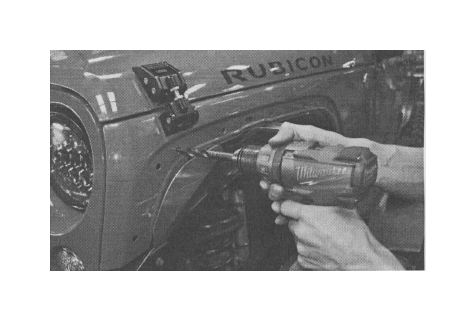

(2) #8-18 X 1/2 washer head self-tapping sheet metal screw (28) #6-32 X 3/8 SS Button Head Cap Screw

(28) #6-32 SS Nylon Insert Lock Nut (28) #10 SS Flat Washer

(4) 5/16" SAE High Strength Flat Washer

(4) 5/16.18 Gr8 Serrated Flange Nut

(2) 5/16-18 Nut-Sert

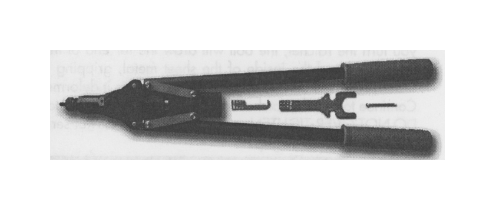

(1) 5/16" Nut-Sert Install Tool - includes:

(1) 5/16-18 X 2 Gr5 Hex Head Cap Screw

(2) 5/16" SAE Hardened Flat Washer

(1) 3/8-16 X 1.1/8 Coupling Nut

(1) 5/16-18 Nut-Seri

INSTALLATION NOTES

The following procedures for Installation of the Poison Spyder JK Front Inner Fenders assumes that Poison Spyder Crusher Flares have already been installed, or are being installed concurrently with the Inner Fenders. If the Crusher Flares were installed by someone else or if it has been a long time since they were installed, it might be helpful to take another look at the Crusher Flare installation instructions to re-familiarize yourself with certain aspects of that installation process and the components used. That knowledge may be helpful in installing these Inner Fenders.

If installing the Inner Fenders with the stock plastic flares or with other manufacturers' aftermarket flares, some creative problem solving may be necessary on the part of the installer, as Poison Spyder can not foresee all potential problems associated with installing these parts with other manufacturer's products.

INSTALL PROCEDURE

1. Park vehicle on a level surface and set the emergency brake. Wear eye protection beyond this point.

IMPORTANT The Mesh Inserts supplied with this kit have been laser cut from stainless steel wire mesh. This may leave some of the edges and cut wire ends sharp. It is recommended to handle the Mesh Inserts with gloves during the installation process, in order to avoid cuts and knicks to hands and arms. At the installers discretion, you may choose to sand or file any sharp edges prior to installing the Mesh Inserts on to the Inner Fender panels. Note that after final installation on the Jeep, the edges of the Mesh Inserts will be concealed and in an area that is not normally accessed by hands.

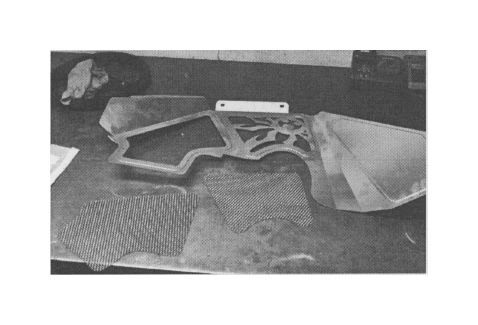

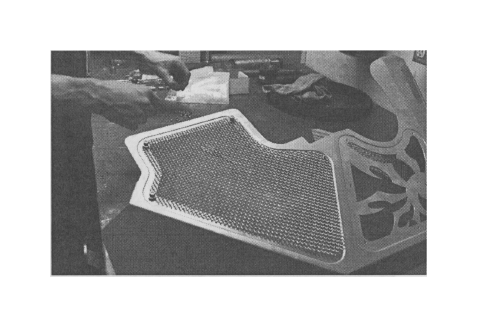

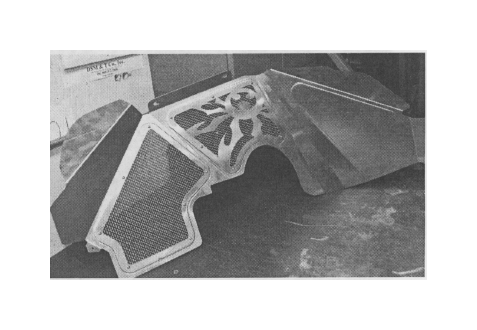

2. Pre-assemble the Inner Fender assemblies. Begin by laying out each Inner Fender piece along with one each of Mesh Insert A and Mesh Insert B, per Inner Fender. It will be evident how the Mesh Inserts fit into the Inner Fenders based on their shape.

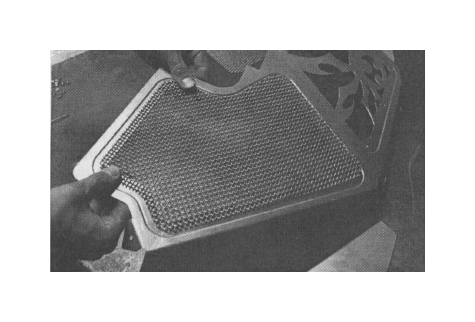

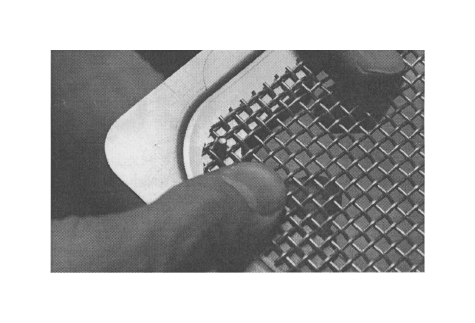

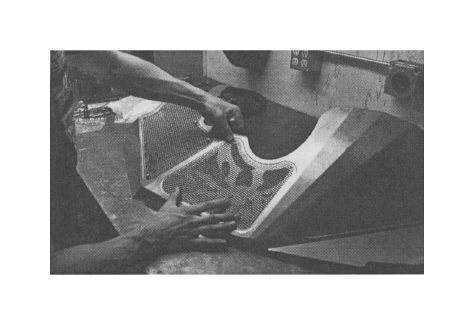

3. To attach the Mesh Inserts to the Inner Fender, begin by placing a Mesh Insert against the corresponding place in the JK Inner Fender. The shape of the Mesh Insert will be slightly larger than the vent hole in the Inner Fender. Be sure to place the Mesh Insert against the back-side of the Inner Fender, as shown in the following photo. The Mesh Insert will seat within the offset area created by the bead-roll around the vent opening. Adjust the position of the Mesh Insert so that it overlaps the edge of the vent hole equally, all the way around its perimeter (it must be centered in place).

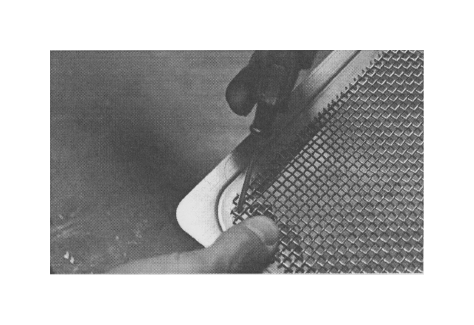

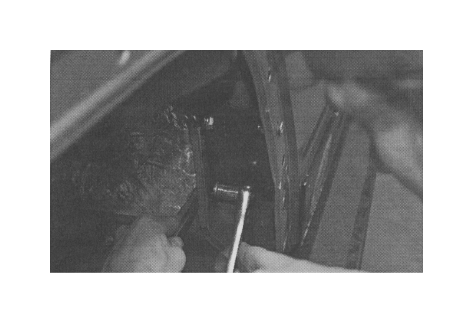

4. The supplied hardware is used to attach the Mesh Insert to the Inner Fender by passing the screw through the hole in the Inner Fender, then through one of the gaps in the mesh. What makes this slightly tricky is that the threads on the screw are slightly larger than the openings in the mesh, so a small Phillips screwdriver or similar tool must be used to slightly round-out the square opening in the mesh where the screw will pass through. DO NOT try to round-out all of the screw locations at once. Work one at a time, begining at a corner. With the Mesh Insert centered as evenly as possible within the vent hole of the Inner Fender, identify the opening in the mesh that most closely corresponds to the existing hole in the Inner Fender. Then use the screwdriver or similar tool to round-out ONLY that opening in the mesh.

5. It will only require slight working of the mesh to enable the screw to pass through. When ready, pass the stainless steel button head cap screw first through the screw hole in the Inner Fender, then through the just-rounded opening in the Mesh Insert.

6. Place a supplied flat washer and nylon insert lock nut onto the screw. At this time leave these fasteners only finger-tight against the nylon insert. This will allow some freedom of movement as the rest of the fasteners are installed.

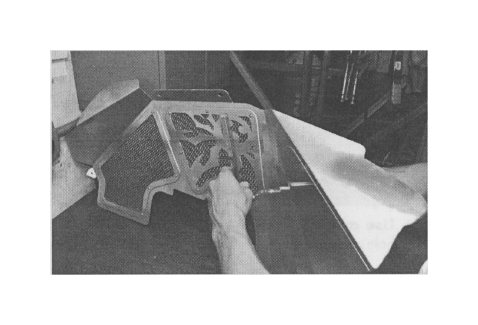

7. Continue with the rest of the fasteners on the same Mesh Insert. Work one fastener at a time, beginning with the adjacent fastener to the previous, and work in a circle until all fasteners are installed. Between each fastener, re-check that the Mesh Insert is still centered around the edges of the vent hole in the Inner Fender.

8. Continue with the remaining Mesh Inserts, following the same procedures as for the previous insert. Note that there may be instances where the cut edge of the wire mesh leaves a loose wire, or un-closed opening, where a screw must pass through. This is OK, as the flat washers will securely hold the mesh in place once all are tightened.

9. Use a hex key and ratchet with socket to tighten each of the screws/nuts to secure the Mesh Inserts into place. Tighten the fasteners in a criss-cross pattern, and check that the Mesh Insert is seating squarely against the Inner Fender without warping, as you tighten each fastener. Also continue to check that the Mesh Insert remains centered.

10. With pre-assembly complete, the Inner Fenders are now ready for installation into the Jeep.

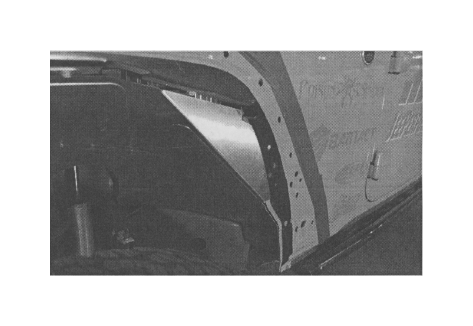

NOTE: With the Vented Inner Fenders pre-assembled, the installation process is identical to the non-vented Inner Fenders. Some of the following photos may depict non-vented Inner Fenders but the procedure is the same.

11. If you still have the trimmed stock plastic inner fenders from a prior Crusher Flare installation, remove them.

12. Optional: apply masking tape to the Jeep's fender, around where the flare attaches. This will protect the Jeep's paint finish in case the flare or the inner fender components are accidentally bumped against it during the following installation procedures.

13. Remove the LED marker light, if it was installed as part of the prior Crusher Flare installation.

14. Unbolt and remove the Crusher Flare.

15. Remove the Crusher Flare Lower Sub-Frame Bracket from the rearward side of the wheel opening.

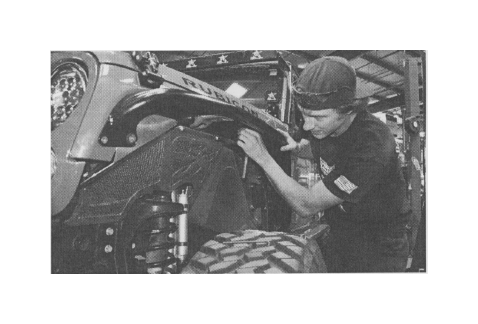

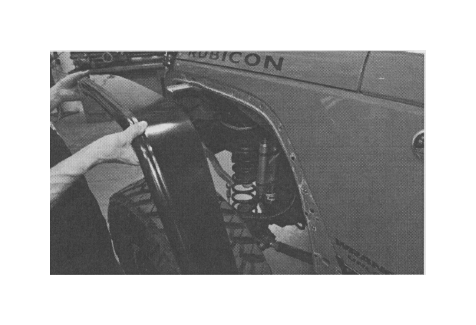

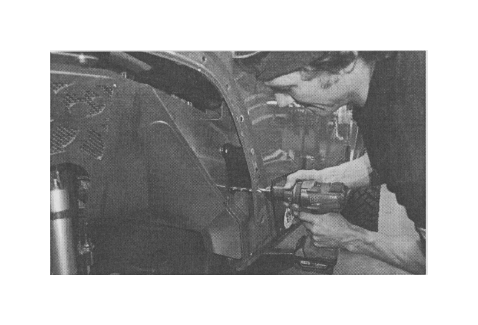

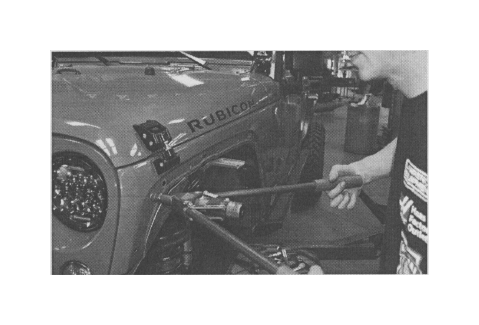

16. Carefully insert the Inner Fender piece into the wheel opening. Make sure the correct piece is being used on each side.

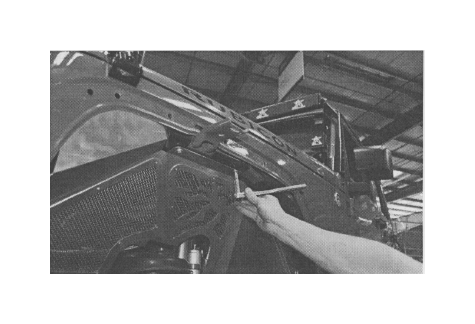

17. Hold the Inner Fender in place while re-installing the OE metric hex head bolts that were removed at the top of the wheel opening. They will pass through the two holes at the top of the Inner Fender, through the Crusher Flare Upper Sub-Frame Bracket, and into the threaded holes in the Jeep's sub-frame.

Make sure the rearward flange of the Inner Fender piece aligns correctly into the pocket where the Crusher Flare Lower Sub-Frame Bracket was removed, then tighten the two OE metric hex head bolts at the top of the Inner Fender

18. Re-install the Crusher Flare Lower Sub-Frame Bracket using ONE of the bolts that were removed, to attach it to the outer sheet metal of the Jeep's fender to hold it into place. Make sure the other hole in the bracket is aligned with the corresponding hole in the Jeep's fender

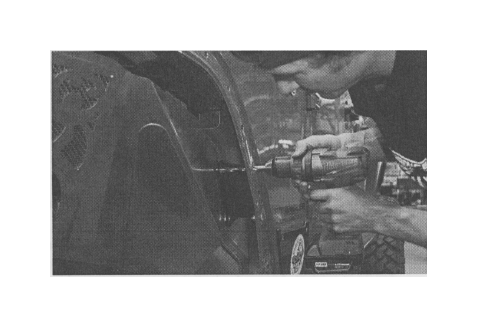

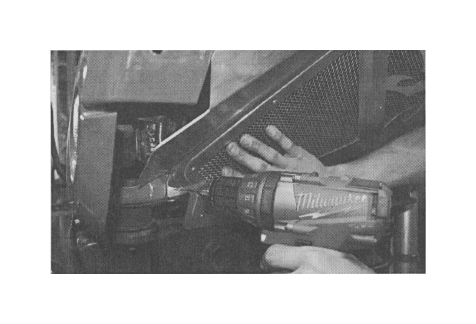

19. Use a 3/8" bit to drill through the second (un-bolted) hole in the Lower Sub-Frame Bracket, using it as a drill guide to drill the corresponding hole through the Inner Fender.

FAQ: Why do I have to drill these holes? Why aren't they already laser-cut into the panel at the Poison Spyder factory?

ANSWER: The JK Inner Fender is designed to fit all revisions of Poison Spyder JK Crusher Flares. The location of the Lower Sub-Frame Bracket has changed slightly through the several revisions of this product over the years, making it impossible to leave a hole that accommodates all variations. The solution is to leave it blank and let the installer place the hole where it needed to be in order to fit whichever revision Crusher Flare is being used.

20. Reinstall the two bolts (inner and outer) on to the Crusher Flare Lower Sub-Frame Bracket at the hole location that was drilled in the previous step. IMPORTANT: On the INNER bolt, use the supplied 5/16-18 serrated flange nut on the inside of the Jeep's tub, rather than the nylon insert lock nuts that originally came with the Crusher Flares. The flange nuts will grip and be easier to tighten without keeping a wrench on the nut in a hard-to-reach location.

21. Remove the bolt that was first temporarily installed into the Lower Sub-Frame Bracket, and drill through the Inner Fender at that location using a 3/8" bit, similarly as in previous steps for the other hole location.

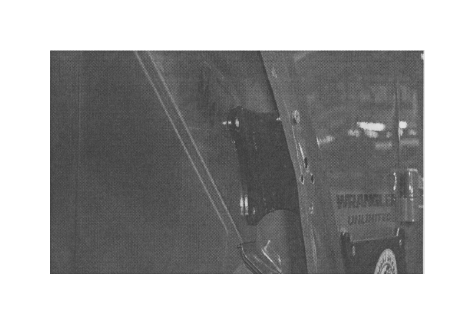

Once this hole has been drilled, remove the outer bolt from the other hole location, install the inner bolt at the new location using another of the supplied serrated flange nuts, leaving the Lower Sub-Frame Bracket installed with only the two inner bolts in place (the two bolts which pinch the Inner Fender between the bracket and the Jeep's inner tub. It may be necessary to enlist the help of a friend to hold a wrench onto the flange nut behind the Inner Fender (accessed from below, inside the frame rail).

22. One of the flare mounting bolts is in a location that will be impossible to access the nut on the back side of the panel after the Inner Fenders have been installed. A 5/16-18 nut-sert will need to be installed in this difficult bolt hole location, which is directly below the hood latch on either side of the Jeep. Drill this hole out to 17/32" in preparation for installing one of the supplied 5/16-18 nut-serts.

NOTE: It is HIGHLY RECOMMENDED to invest in a professional nut-sert installation tool, such as the Marson Giant Threadsetter, available from online tool sellers.

The professional tool will make the installation of nut-serts MUCH easier than using the free tool included in this kit, and it will come in handy with future product installations as well. If using a professional nut-sert installation tool, follow the directions that came with the tool and skip the next three steps of these instructions.

The simple "tool" included with this product is admittedly frustrating to use, however it will work for those with patience who would like to save the cost of the professional tool. If using the simple tool included with this product, continue through the following steps.

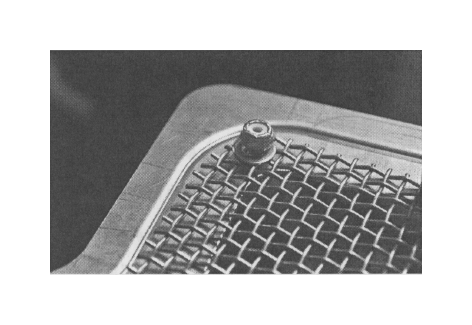

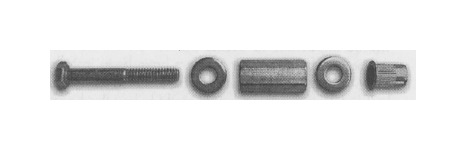

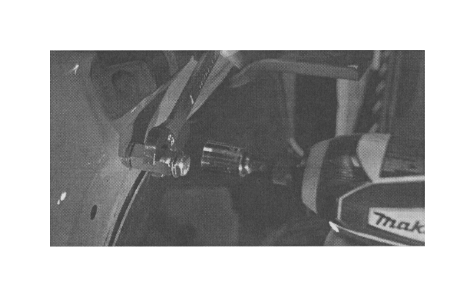

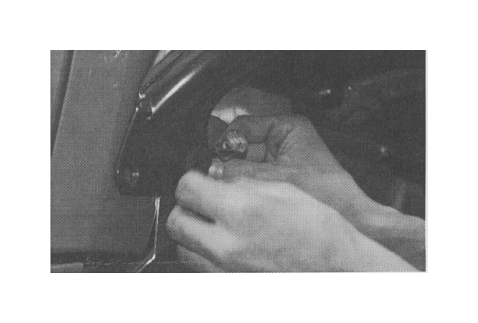

23. The provided nut-sert install tool consists of a bolt, two washers and a coupler (long) nut. Assemble these items as shown (bolt—washer—coupler nut—washer—nut-Bert). Insert the nut-sert end into the hole you drilled.

24. Use an open end wrench to hold the coupler nut stationary while turning the head of the bolt clockwise with a ratchet (or small impact wrench) and socket. As you turn the ratchet, the bolt will draw the far end of the nut-sert toward the inside of the sheet metal, gripping it with the knurled outside edge of the nut-sert as it deforms. Continue to turn the ratchet until the nut-sert is fully seated. DO NOT OVER-TIGHTEN as you can damage the nut-sert, or cause it to lose its grip.

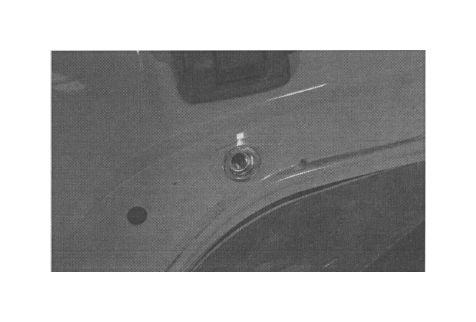

25. Once the nut-sert has seated correctly, loosen the bolt then remove it and the rest of the tool from the nut-sert. Install a new nut-sert onto the tool, oriented the same as the last, and set it aside until your next nut-sert installation. Inspect the nut-sert to make sure it is properly seated and that the surrounding sheet metal isn't excessively deformed. Note that some deformation of the sheet metal is normal, and that it will be covered by the part after installation.

If you "spin" a nut-sert: That is, if it loses its grip due to over-tightening or improper installation, the quickest, easiest fix is to use a MIG welder to place a small tack weld at the edge of the nut-sert flange. Before applying the tack weld, sand or grind the paint from a very small area of the sheet metal where the tack weld will be. Then insert a screw into the nut-sert to protect the threads from weld splatter. Only apply a very small tack or two, as you do not want to heat up and deform the nut-sert or the sheet metal. Then grind the tack(s) smooth and apply touch-up paint to prevent rust.

26. Re-hang the Crusher Flare, installing the forward-most bolt and the lower bolt at the Lower Sub-Frame Bracket (at the rear of the flare). Make sure all of the flare's mounting bolts align properly into their holes.

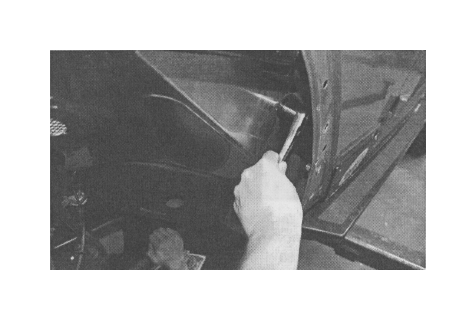

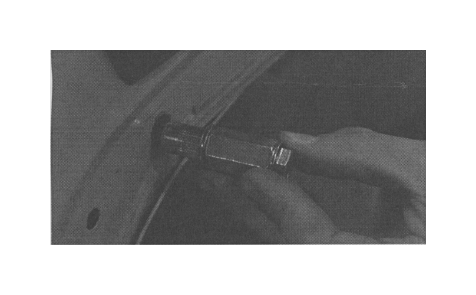

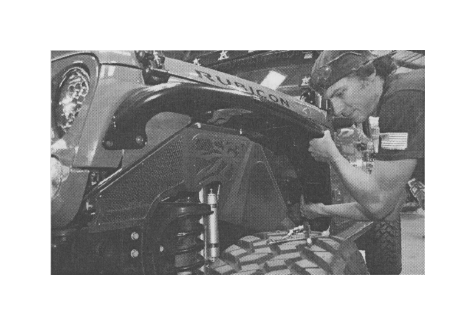

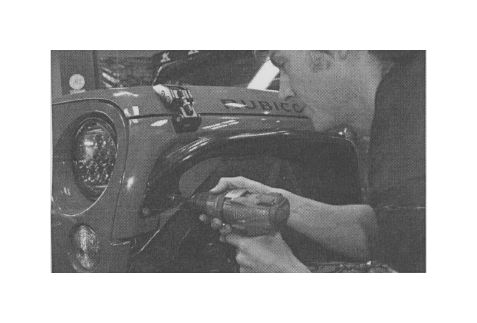

27. At the front-lower corner of the Inner Fender, find the screw-tab which should be resting against the Jeep's body tub sheet metal just above the forward body mount. It may need to be pushed slightly into place. Use the supplied self-tapping sheet metal screw to secure the Inner Fender to the body tub at this screw-tab location. The following photo depicts drilling a pilot hole

28. Use a rotor-broach, hole-saw or step-bit to drill out the 3/4" hole at the forward LED lamp location. If using a rotor-broach or hole-saw, it may be possible to use the hole in the Crusher Flare as the drill guide. If using a step-bit it will probably be necessary to temporarily remove the Crusher Flare after marking the hole location, but before drilling the hole.

FAQ: Why do I have to drill this hole? Why isn't it already laser-cut into the panel at the Poison Spyder factory?

ANSWER: The JK Inner Fender is designed to fit all revisions of Poison Spyder JK Crusher Flares. The location of the LED marker lamp hole has changed slightly through the several revisions of this product over the years, making it impossible to leave a hole that accommodates all variations. The solution is to leave it blank and let the installer place the hole where it needed to be in order to fit whichever revision Crusher Flare is being used.

29. Remove the Crusher Flare (if it wasn't already removed in the previous step)

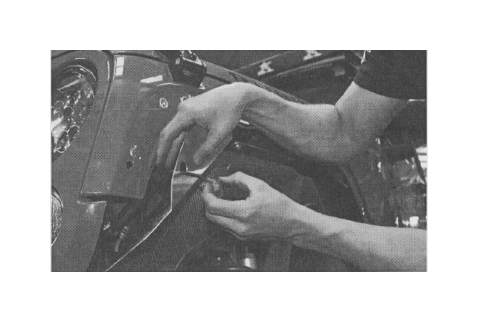

30. Re-install the 3/4" LED marker lamp into the designated hole in the Crusher Flare, taking advantage of the clearance afforded by the new corresponding hole in the Inner Fender. It will be necessary to loosen/remove several of the bolts holding the Inner Fender to the Jeep, so they may be pulled away slightly to gain access behind the panel to re-attach the wiring and install the lamp.

31. Re-install the Crusher Flare while feeding the 3/4" LED lamp through the corresponding light mount hole (it will be necessary to leave the rubber grommet disengaged from the barrel of the lamp.

32. Re-install any removed fasteners, then go back over every bolt on the Crusher Flare and the JK Inner Fenders to ensure that each is tight. Push the LED lamp into place within its rubber grommet.

33. Remove any protective masking tape that may have been applied at the beginning of the installation.

34. Repeat the procedure to install the Inner Fender on the opposite side of the Jeep.

Congratulations, you have completed the installation of your Poison Spyder JK Front Inner Fenders!